Chemical adding device for pulping process

A technology for adding devices and chemicals, used in textiles and papermaking, cellulose treatment with microorganisms/enzymes, raw material separation, etc. It can solve the problem of affecting the simultaneous operation of chemicals and pulping, inability to measure and observe, and inaccurate additions, etc. problem, to achieve the effect of convenient replacement, strong applicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

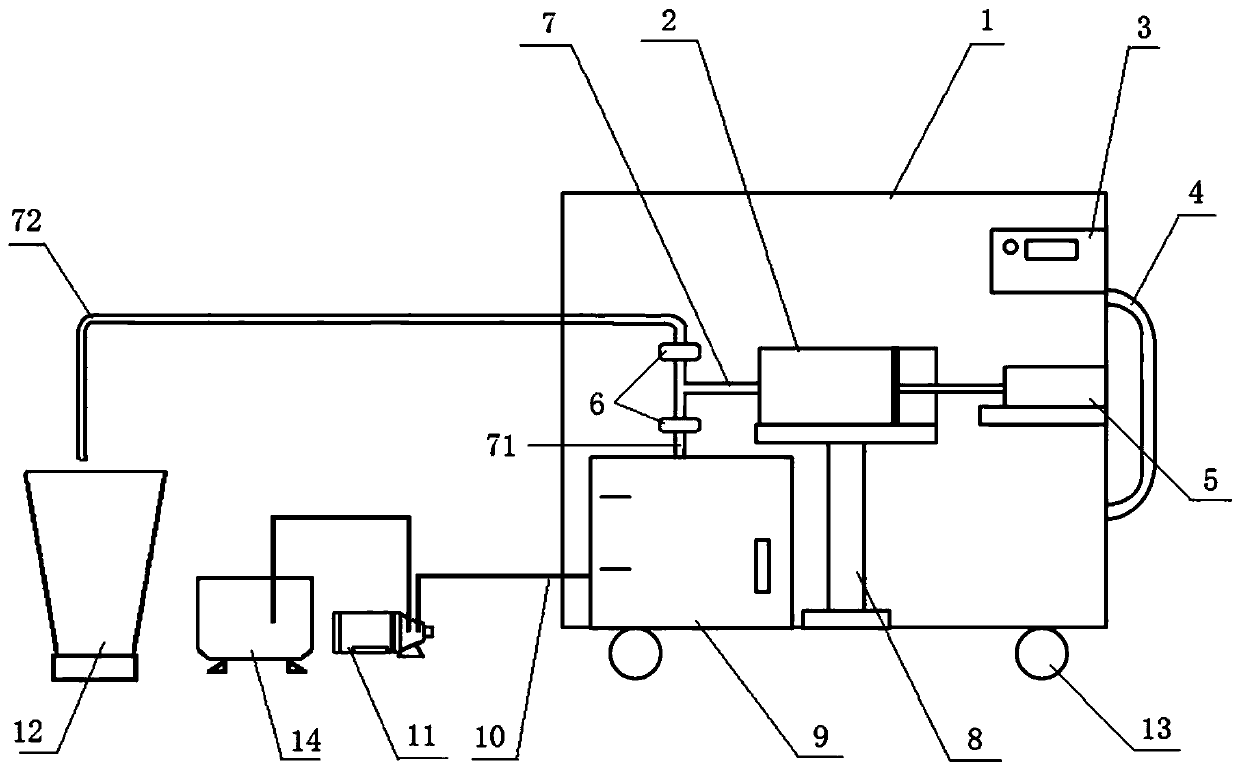

[0030] like Figure 1 to Figure 3 As shown, the present invention relates to a chemical adding device for pulping process, including a frame 1 , a dosing mechanism 2 , a telescopic cylinder 5 , a controller 3 , a dosing barrel 9 and a pulper 12 .

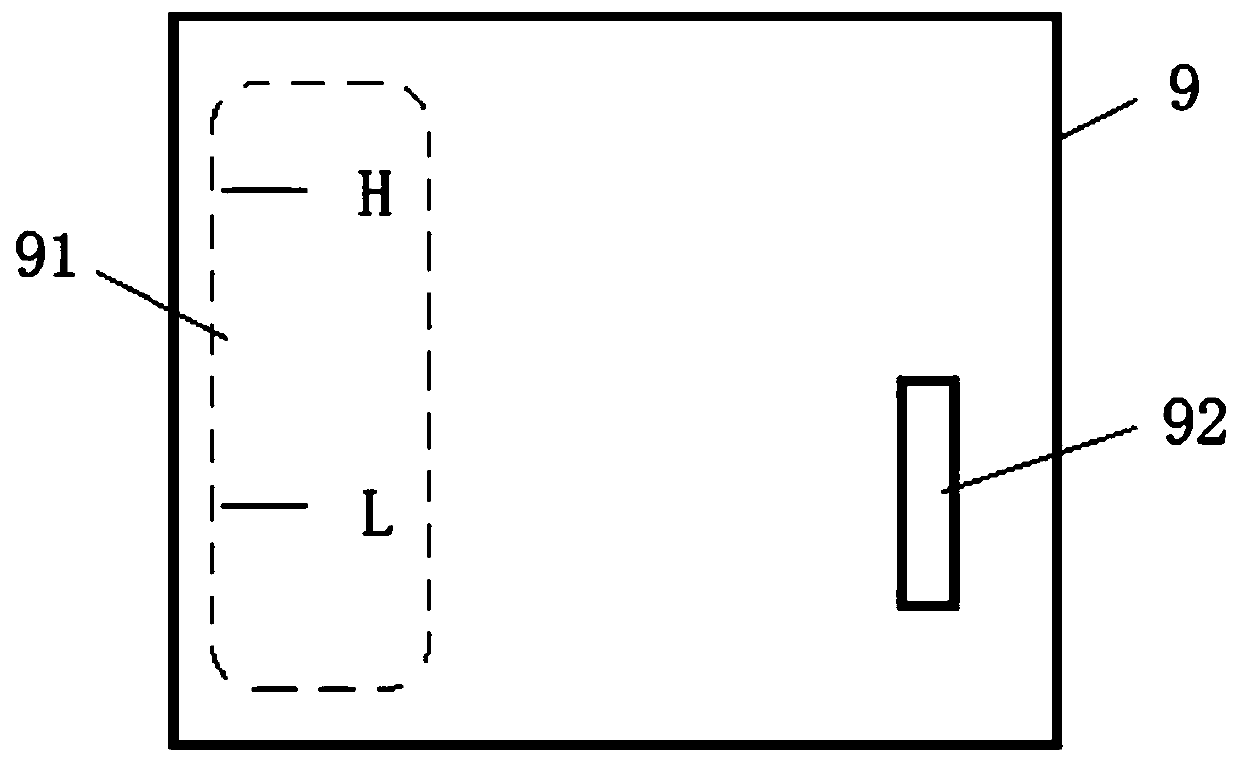

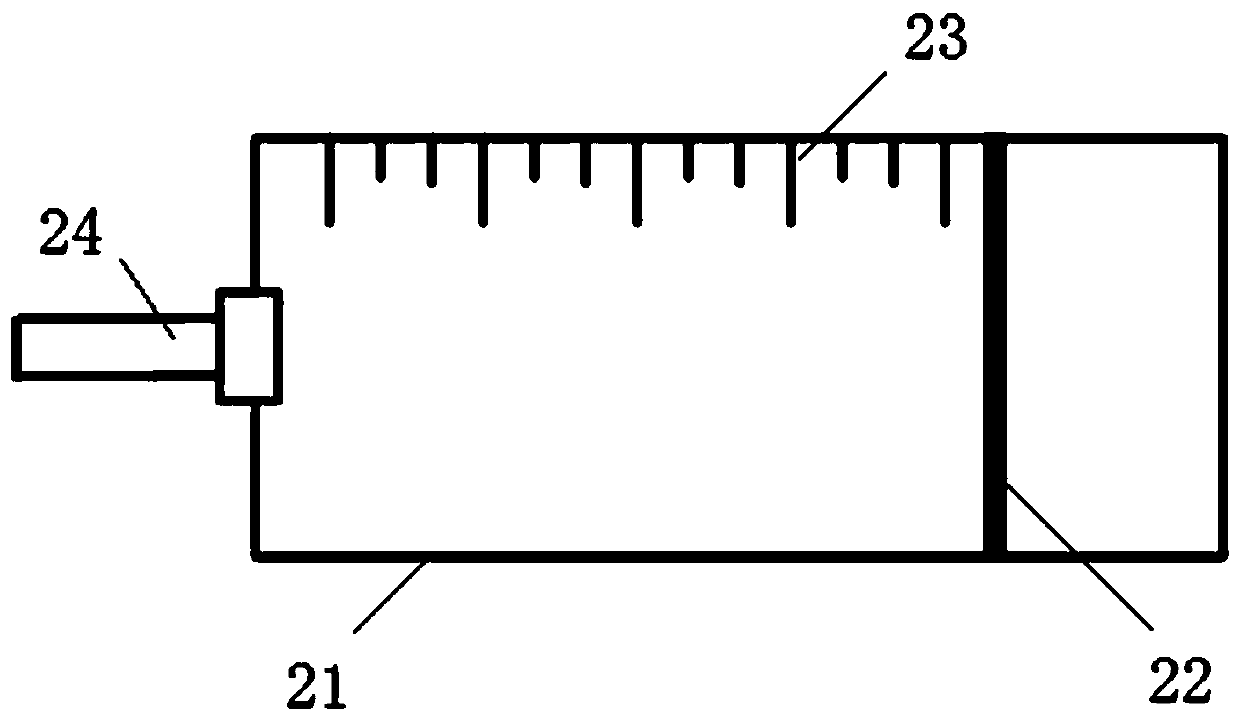

[0031] The frame 1 of the present invention is a semi-enclosed structure. Four rollers 13 are symmetrically arranged at the bottom of the frame 1 . The dosing barrel 9 is fixed on the inner wall of the bottom plate of the rack 1 , the dosing mechanism 2 is fixed on the inner wall of the bottom plate through the bracket 8 , and the height of the dosing mechanism 2 is higher than that of the dosing barrel 9 . The telescopic cylinder 5 and the controller 3 can be fixed in the frame 1 through a structure such as a fixing plate, and the controller 3 is connected to the telescopic cylinder 5 . The dosing mechanism 1 includes a casing 21 , a piston 22 and an infusion tube 23 . The casing 21 is a transparent structure, and the casing 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com