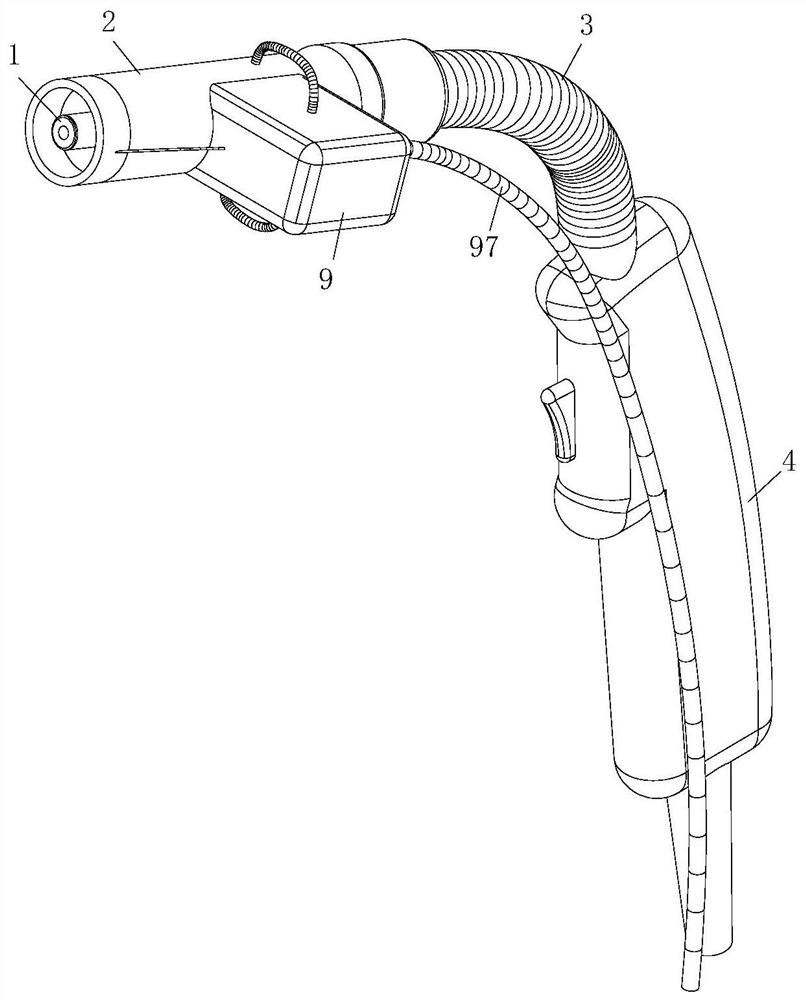

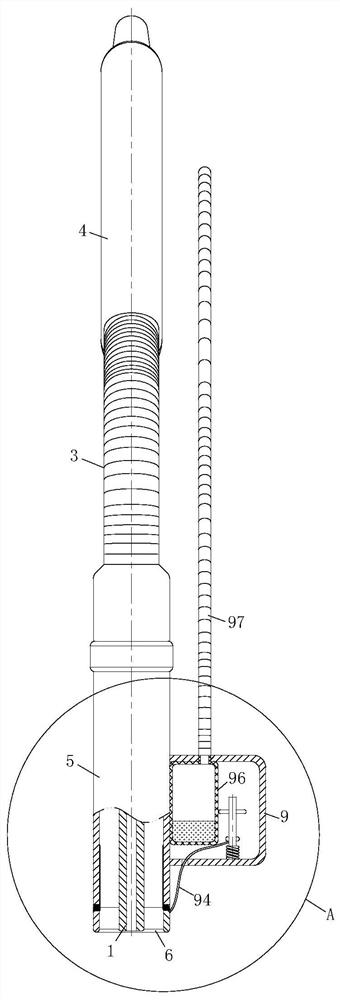

A welding torch head

A welding torch and torch head technology, which is applied in the field of electric welding equipment, can solve problems such as difficult operation, damage to the protective cover and welding tip, and large welding current, and achieve the effect of strengthening the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

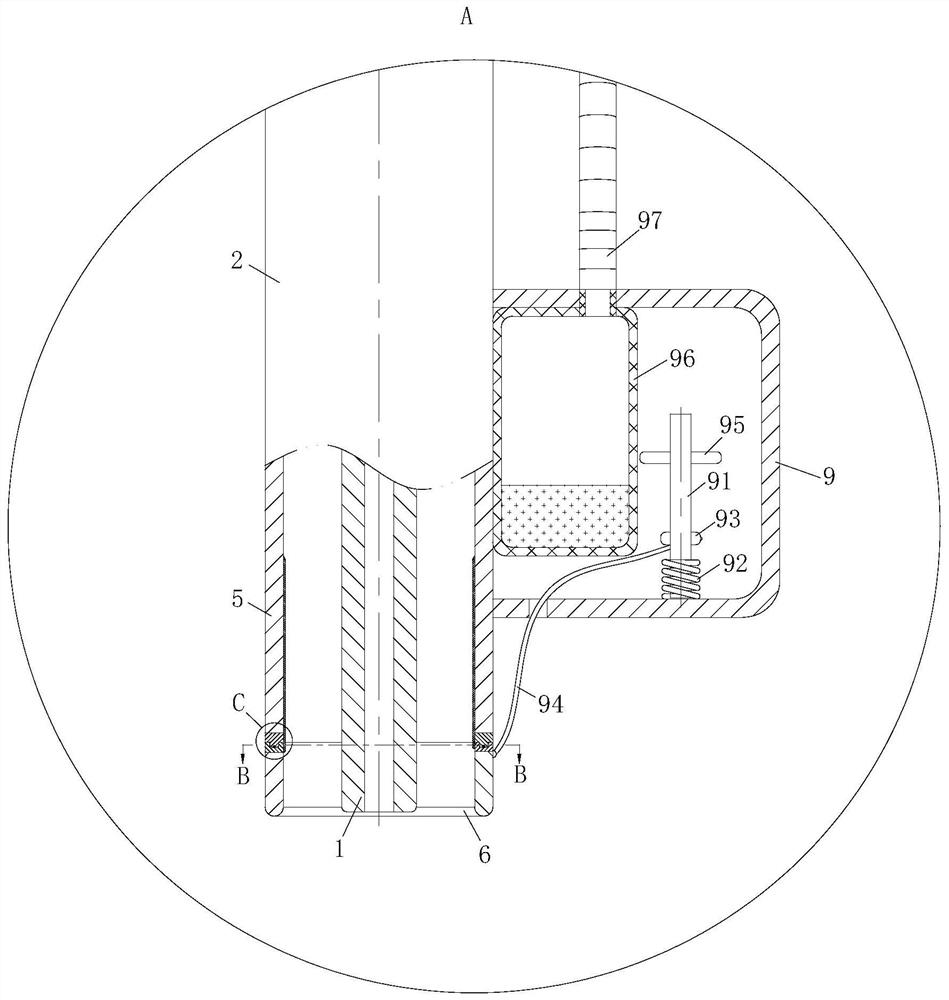

[0028] As an embodiment of the present invention, the number of grooves 81 on the second ring magnet 8 is at least three and arranged evenly in a ring, and the distribution form and number of the scrapers 21 are the same as the grooves 81; At the same time, the number of grooves 81 on the second ring magnet 8 is set to at least three and is uniformly distributed in a ring, and the distribution form and quantity of the scrapers 21 are the same as the grooves 81, which increases the number of jobs of the scrapers 21 and greatly reduces The working stroke of the scraper 21 is improved, so that the scraper 21 can quickly scrape off the welding slag on the inner wall of the upper sheath 5, which improves the working efficiency of the scraper 21, and the reduction of the working stroke of the scraper 21 also reduces the surface damage of the scraper 21 when it is working. The amount of residual welding slag makes it easier for the push plate 83 to shake off and remove the residual we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com