Paperboard stamping forming device and method

A stamping forming and cardboard technology, which is applied in the field of stamping and forming equipment for paper materials to meet the depth requirements, reduce cracks and improve the deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

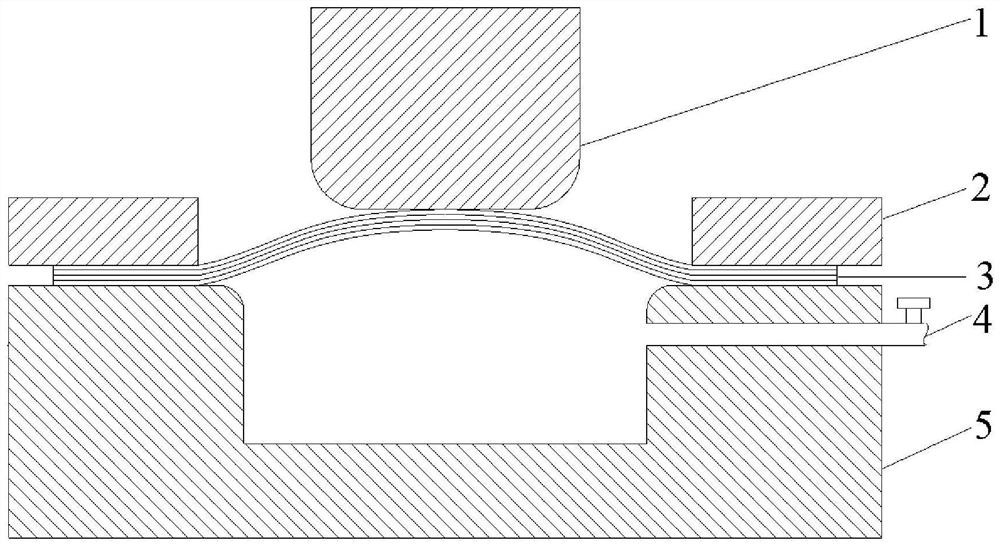

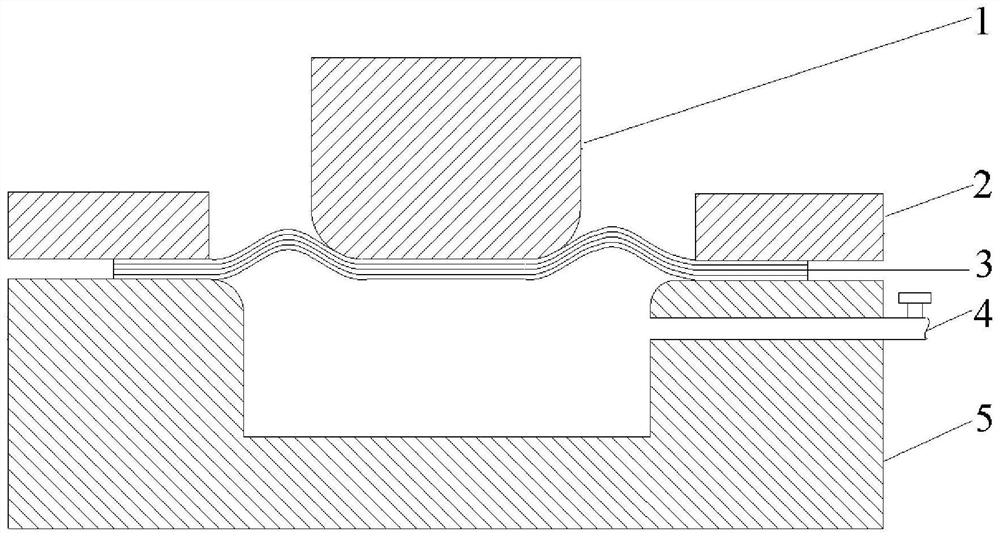

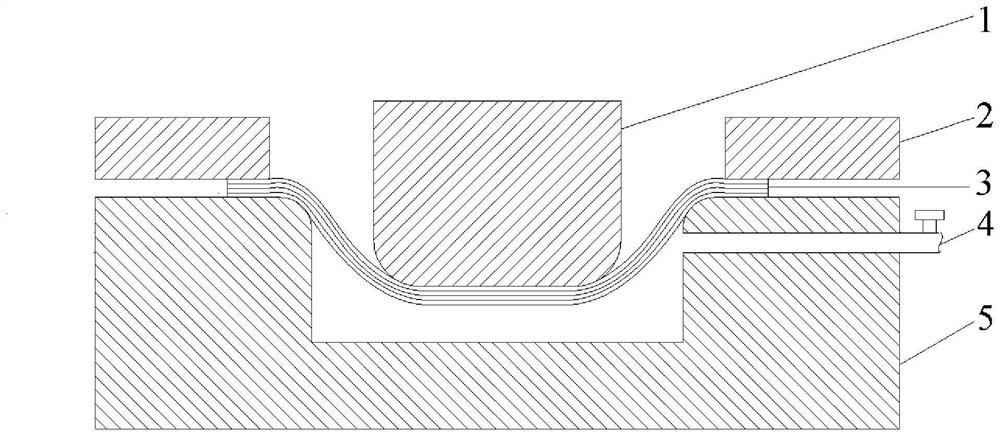

[0031] In an exemplary embodiment of the present invention, as Figure 1-Figure 3 As shown, a cardboard stamping and forming device is given.

[0032] like figure 1 The shown cardboard stamping and forming device is used for stamping and forming paper-based materials to obtain paper containers, especially for stamping and forming of cardboard 3, by deforming the cardboard 3 twice in opposite directions, the deformation ability of the entire area of the cardboard 3 is exerted, and the The deformable amount of the cardboard 3 can reduce cracks, breakage and other problems during the forming process, and improve the forming depth of the paper container.

[0033] The cardboard stamping and forming device mainly includes a stamping element for providing stamping action and a pressing component 4 for providing pre-deformation. 3. Pre-deformation is generated, and the direction of the pre-deformation is opposite to the required stamping and forming direction, and then the pressin...

Embodiment 2

[0051] In another exemplary embodiment of the present invention, as Figure 1-Figure 3 As shown, a cardboard stamping forming method is given.

[0052] Cardboard stamping and forming methods, including:

[0053] Along the thickness direction of the cardboard 3, the multi-layer cardboards 3 are stacked in sequence, and the stacked cardboards 3 are deformed together;

[0054] Clamp the edge of the cardboard 3 and apply a pre-action force to the cardboard 3, so that the cardboard 3 has a pre-deformation in the opposite direction to the stamping deformation;

[0055] Keeping the pre-acting force, press the cardboard 3, and overcome the pre-acting force to produce the punching deformation of the cardboard 3.

[0056] In order to keep the paperboard 3 in a proper deformation state, one or more parameters of pressure, temperature and humidity acting on the paperboard 3 are controlled when the pre-force is applied.

[0057] In addition, it is also necessary to adjust the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com