High-titanium molten blast furnace slag hot charging furnace device

A technology of blast furnace slag and high titanium type is applied in the field of hot charging furnace device of high titanium type molten blast furnace slag, which can solve the problems of manual operation, inability to guarantee sealing, equipment influence, etc., and achieves convenient operation, simple structure and low procurement cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

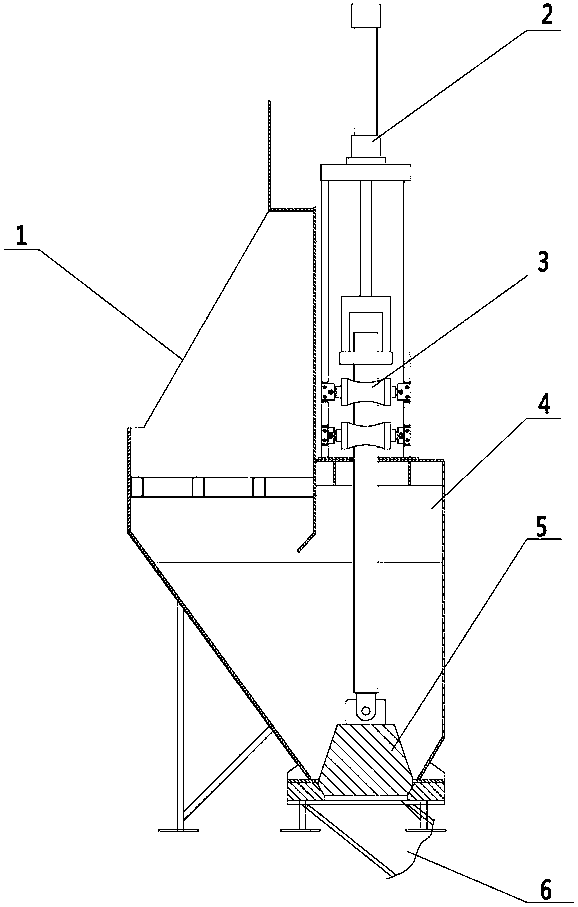

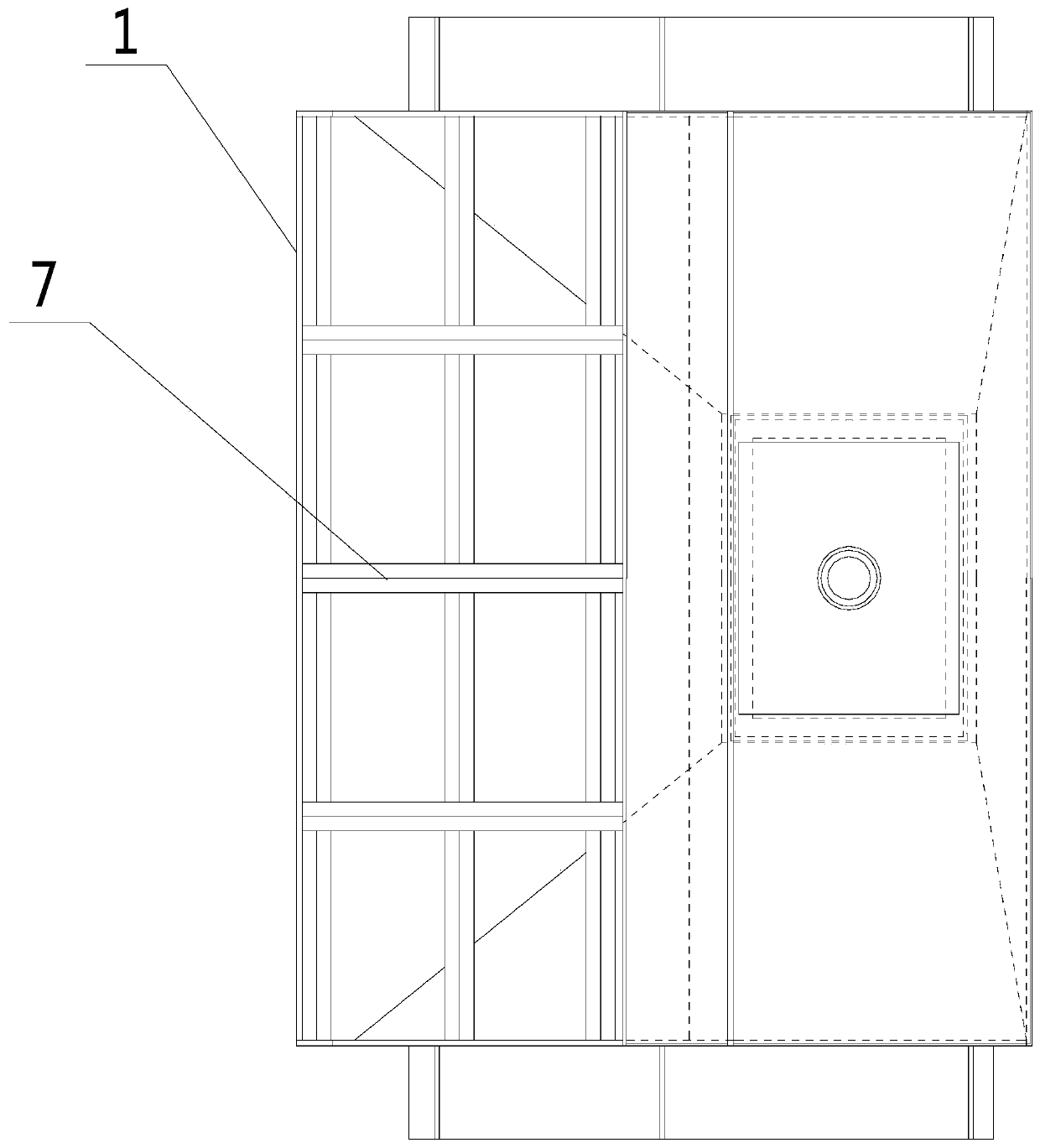

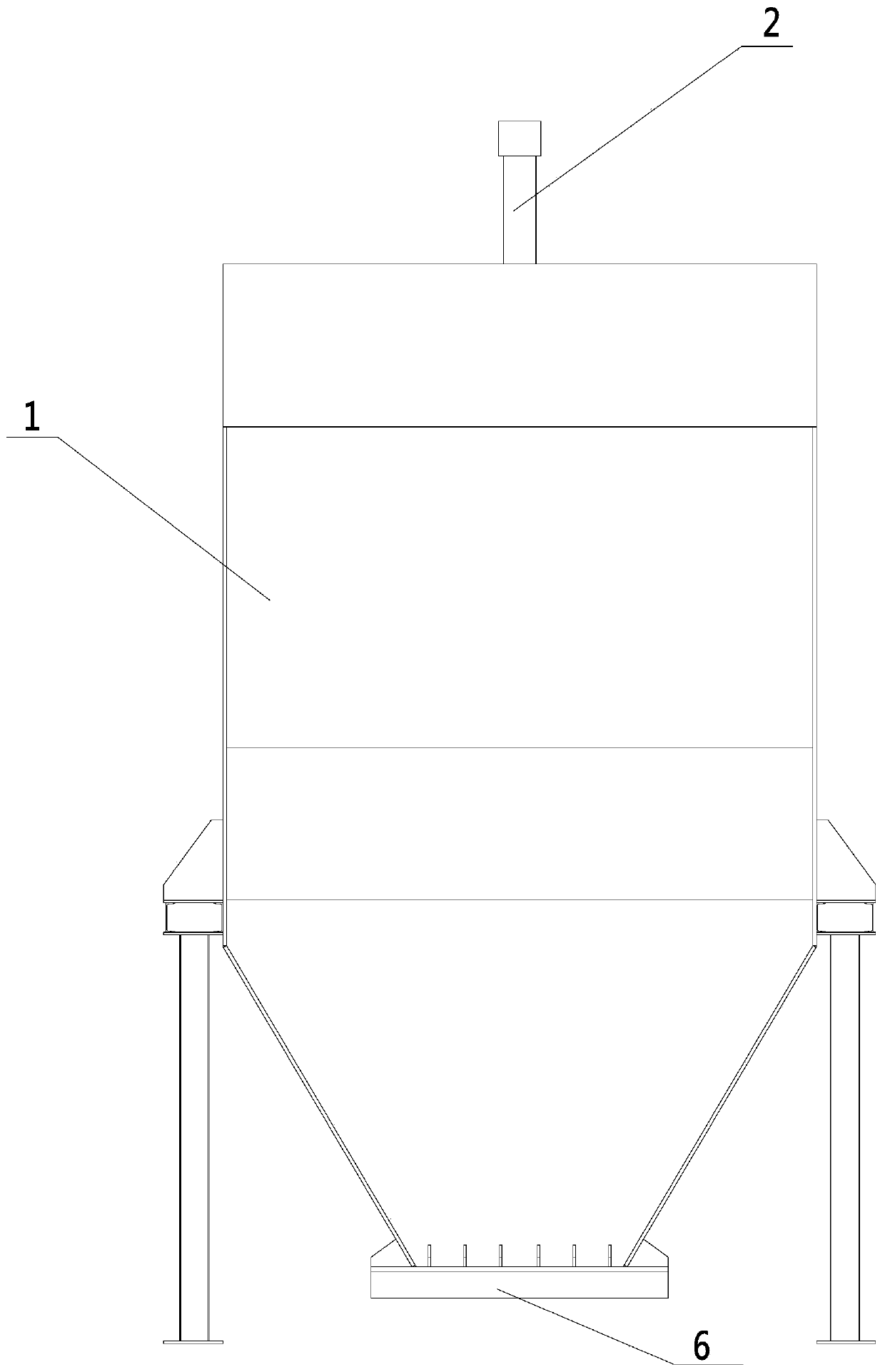

[0015] Such as figure 1 , figure 2 , image 3 The shown high-titanium type molten blast furnace slag hot charging furnace device includes a device body 4, and the device body 4 includes a hot slag inlet 1, a slag outlet 6 and a gate sealing device arranged in the device body 4. The gate The sealing device seals the slag outlet 6 by being in close contact with the slag outlet 6, wherein a slag skimming plate structure 7 is arranged at the hot slag inlet 1 .

[0016] In actual use, in order to reduce production energy consumption, it is necessary to pour hot blast furnace slag into the carbonization furnace without affecting the carbonization furnace equipment. Therefore, it is very An ideal solution, which can not only ensure that the hot blast furnace slag can enter the carbonization furnace safely, but also avoid the problem of directly introducing the hot blast f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com