Method for preventing calcium, magnesium and iron adhesion blockage at top of chlorination furnace during production of titanium tetrachloride

A technology of titanium tetrachloride and chlorination furnace, applied in the direction of titanium halide, etc., can solve the problem that the outlet pipeline is easy to be blocked, achieve the effects of convenient connection, simple production, and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

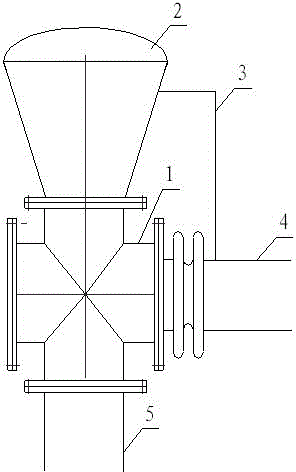

[0021] The invention is a method for preventing calcium, magnesium and iron from adhering and clogging the top of a chlorination furnace in the production of titanium tetrachloride, which can effectively solve the problem that the outlet pipe of the top of the chlorination furnace is easily blocked in the production of titanium tetrachloride , which laid the basic conditions for improving the production and use efficiency of the chlorination furnace.

[0022] It should be pointed out that the top of the chlorination furnace is equipped with an outlet pipeline, and the outlet pipeline discharges the chloride impurity gas formed by calcium, magnesium and iron.

[0023] In the present invention, a smoke exhaust and anti-blocking device is arranged on the outlet pipe, and the device includes a four-way pipe 1, an inverted conical dust collection cover 2, a pressure balance pipe 3, a first gas pipe 4, a second gas pipe 5, Spare pipes and related gate valves, although these configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com