Fastener quenching device

A quenching device and fastener technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of fastener deformation, waste, large temperature difference of fasteners, etc., so as to delay the falling speed, disperse evenly, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

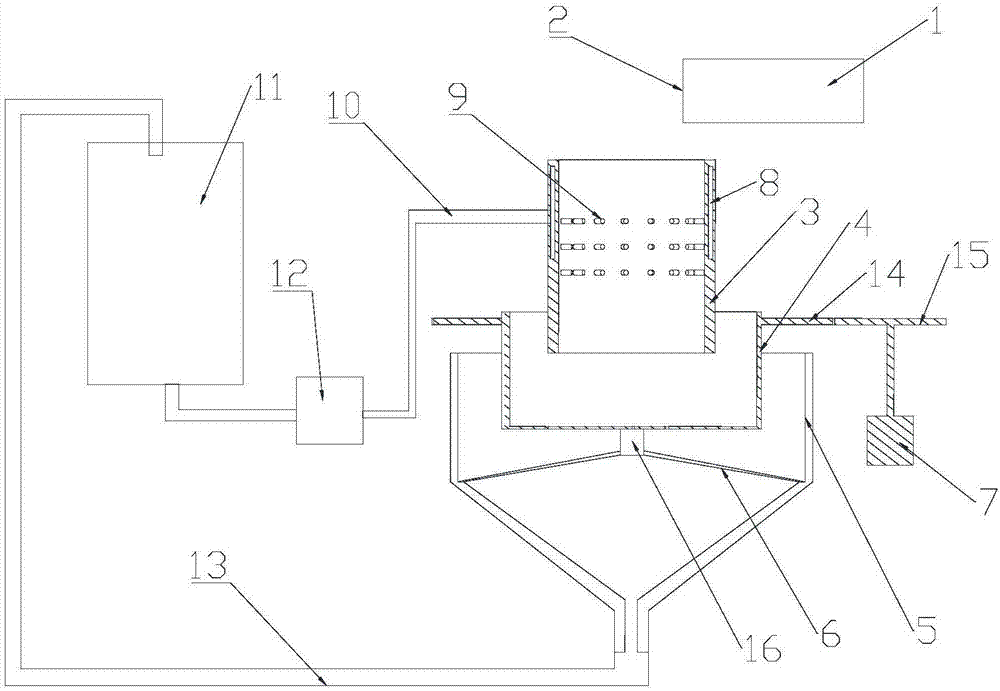

[0011] The present invention will be further described now in conjunction with accompanying drawing.

[0012] like figure 1 As shown, a fastener quenching device includes a quenching furnace 1, and the quenching furnace 1 includes a discharge port 2, a tubular spray pipe 3 is provided below the discharge port 2, and the pipe at the upper end of the spray pipe 3 The outlet is located below the discharge port 2, and the spray pipe 3 is provided with a charging barrel 4, and the nozzle at the lower end of the spray pipe 3 extends into the charging barrel 4, and the charging barrel 4 is located in the oil collecting barrel 5, and the oil collecting barrel 4 A support 6 is installed in the barrel 5, and the charging barrel 4 is installed on the support 6 rotatably around its axis. The side wall and the bottom of the barrel 4 are grid-shaped, and the charging barrel 4 is controlled by a motor 7 to rotate. The pipe wall of the spray pipe 3 is provided with a sealed oil chamber 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com