A posture solution and prediction method of mining and transportation equipment in fully mechanized mining face

A fully mechanized mining face and attitude technology, applied in navigation calculation tools and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

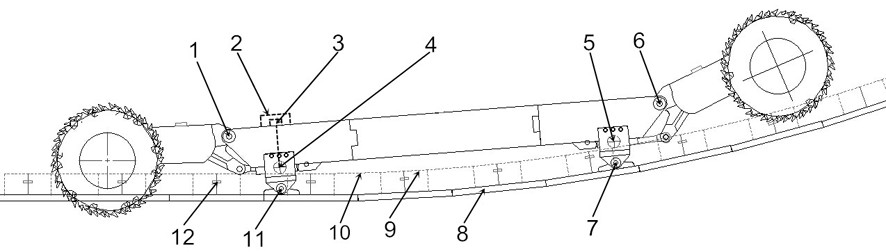

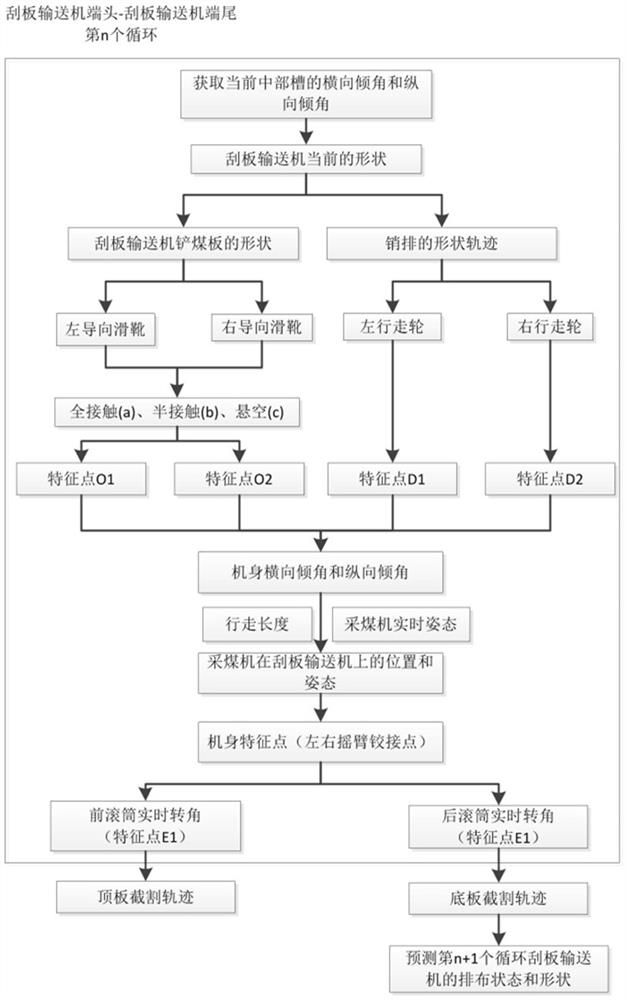

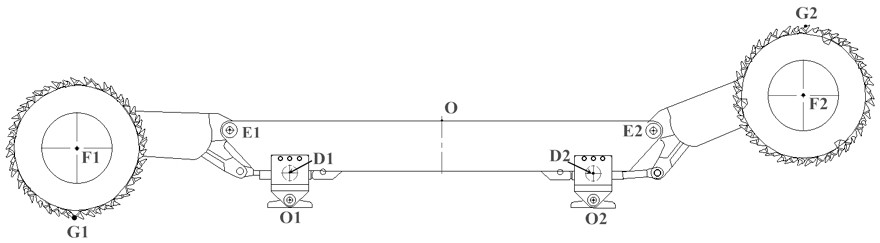

[0067] Implement the above-mentioned problem of positioning and attitude determination of shearers and scraper conveyors in fully mechanized mining working faces of coal mines, and propose a method for solving and predicting attitudes facing mining and transportation equipment in fully mechanized mining working faces. The method for positioning and determining attitude is The method is to obtain the shape by acquiring the posture data of the scraper conveyor in real time under the composite working condition of the uneven bottom plate of the fully mechanized mining face, and to obtain the shape through the contact and contact between the left and right support slide shoes of the shearer and the coal shoveling plate of the scraper conveyor. The coupling relationship between the left and right travel wheels and the pin row is used to solve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com