Feedforward compensation design method of thermal power generating unit AGC system

A technology of feed-forward compensation and thermal power units, which is applied in general control systems, control/regulation systems, instruments, etc., can solve the problems that are difficult to meet the AGC adjustment rate, adjustment accuracy and response time at the same time, and achieve shortened response time and multi-assessment The effect of increasing the power and improving the response accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

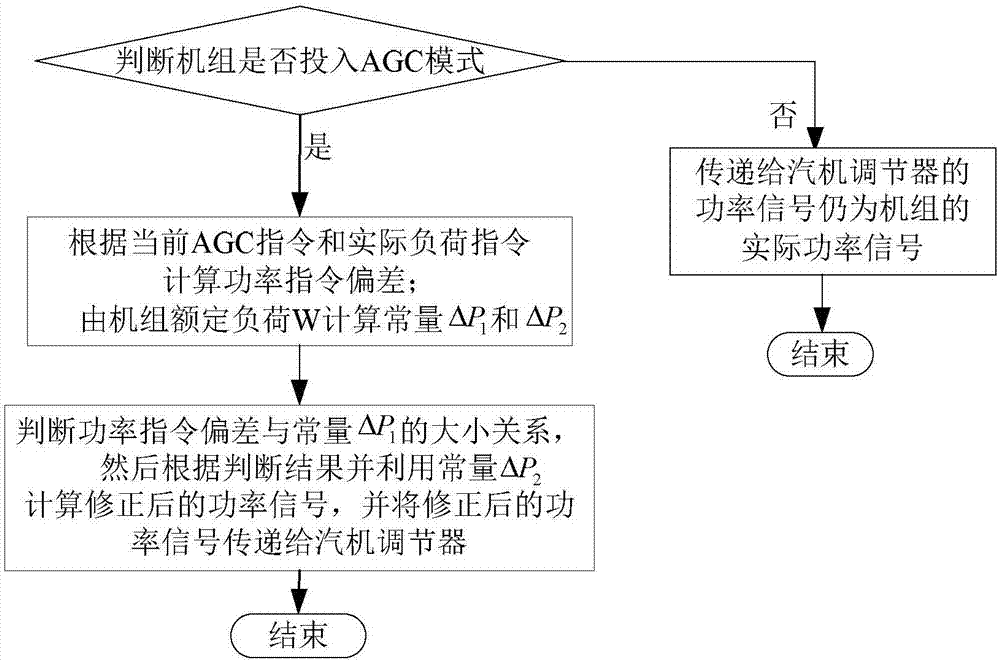

Method used

Image

Examples

Embodiment 1

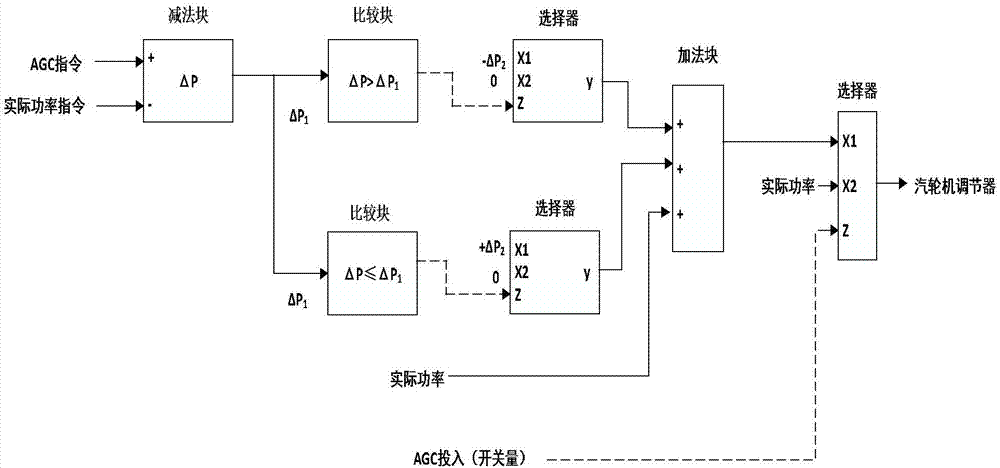

[0051] Complete the construction of the functional relationship and the calculation of the constants in the AGC feed-forward compensation logic of the 300MW unit through steps 1 to 3, and the calculation result is ΔP 1 =1.2,ΔP 2 = 2.8, according to image 3 The logical structure shown is designed and implemented in the unit DCS. Comparing the adjustment rate K before and after optimization 1 , Adjustment accuracy K 2 , response time K 3 , as shown in Table 1, after optimization, the adjustment rate K 1 From 1.05 to 1.23, the adjustment accuracy K 2 From 0.85 to 1.50, the response time K 3 From 0.95 to 1.51.

[0052] Generally, the calculation method of the three comprehensive adjustment performance indicators for the AGC assessment of the unit by the power grid is as follows:

[0053] Adjustment rate K 1 Indicates the degree to which the actual adjustment speed of the unit accounts for the standard speed. If the calculated value is less than 0.1, take it equal to 0.1...

Embodiment 2

[0068] Complete the construction of the functional relationship and the calculation of the constants in the AGC feed-forward compensation logic of the 200MW unit through steps 1 to 3, and the calculation result is ΔP 1 =0.7, ΔP 2 = 1.8, according to Figure 4 The logical structure shown is designed and implemented in the unit DCS. Comparing the adjustment rate K before and after optimization 1 , Adjustment accuracy K 2 , response time K 3 , as shown in Table 2, after optimization, the adjustment rate K1 increases from 0.45 to 0.91, and the adjustment accuracy K 2 From 0.95 to 1.52, the response time ratio K 3 Increased from 1.05 to 1.32.

[0069] Table 2 Comparison of parameters before and after optimization of 200MW unit

[0070] AGC performance index

Adjustment rate K 1

Adjustment accuracy K 2

Response timeK 3

before optimization

0.45

0.95

1.05

Optimized

0.91

1.52

1.32

[0071] This strategy improves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com