Sorting system and method

A shelf and reminding device technology, applied in the field of warehousing and logistics, can solve problems such as mistakes and no goods placed, and achieve the effects of reducing labor intensity, facilitating search, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

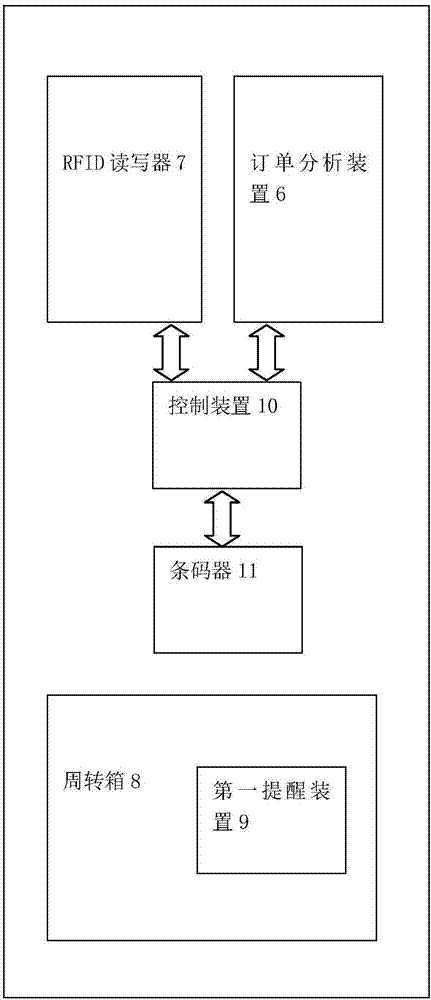

[0069] Such as figure 1 As shown, the picking system includes:

[0070] Several turnover boxes 8, which are used to place commodities;

[0071] Reminding device, it comprises the RFID passive tag and indicator that are connected to each other, and reminding device comprises some first reminding devices 9 that are correspondingly arranged on some turnover boxes 8;

[0072] Graphic code, which is arranged on the first reminding device 9, for identifying the first reminding device 9;

[0073] A control device 10, and an order analysis device 6, an RFID reader / writer 7 and a bar code device 11 connected to the signal;

[0074] Wherein, the order analysis device 6 receives and analyzes the order information, the bar code device 11 scans the graphic code to obtain the first reminder device ID of the corresponding turnover box, and the control device 10 binds the order information with the first reminder device ID of the corresponding turnover box 8, and Control the RFID reader / wr...

Embodiment 2

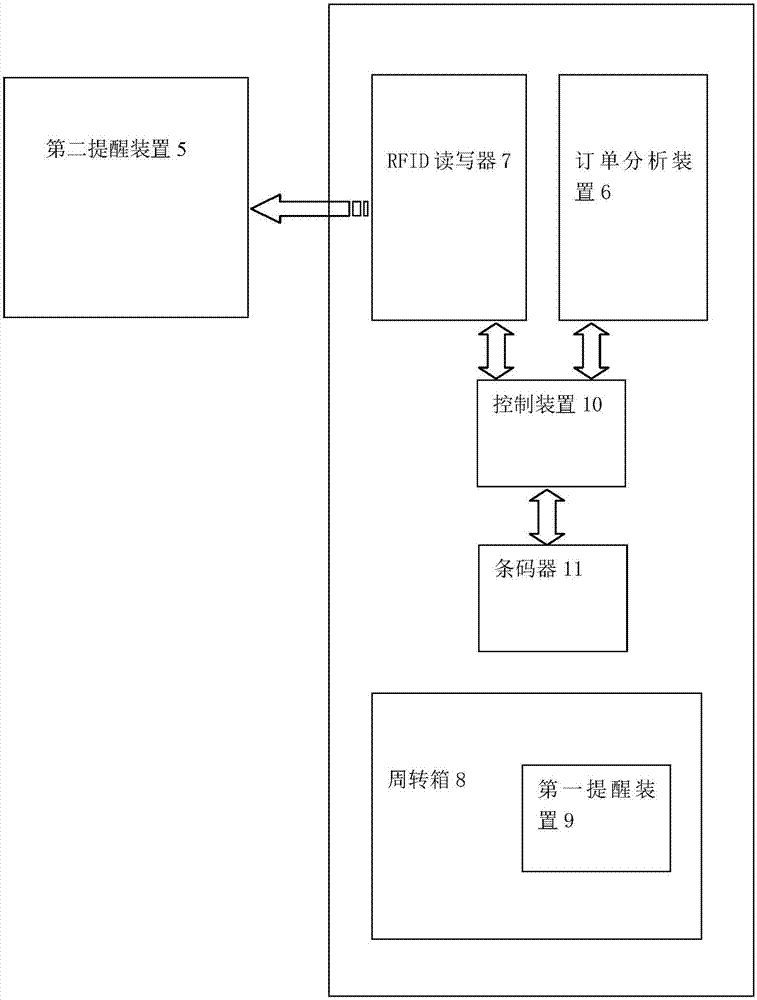

[0076] Such as figure 2 As shown, the picking system includes:

[0077] Several turnover boxes 8, which are used to place commodities;

[0078] Reminding device, it comprises the RFID passive tag and indicator that are connected to each other, and reminding device comprises some first reminding devices 9 that are correspondingly arranged on some turnover boxes 8;

[0079] Graphic code, which is arranged on the first reminding device 9, for identifying the first reminding device 9;

[0080] A control device 10, and an order analysis device 6, an RFID reader / writer 7 and a bar code device 11 connected to the signal;

[0081] Wherein, the order analysis device 6 receives and analyzes the order information, the bar code device 11 scans the graphic code to obtain the first reminder device ID of the corresponding turnover box, and the control device 10 binds the order information with the first reminder device ID of the corresponding turnover box 8, and Control the RFID reader / w...

Embodiment 3

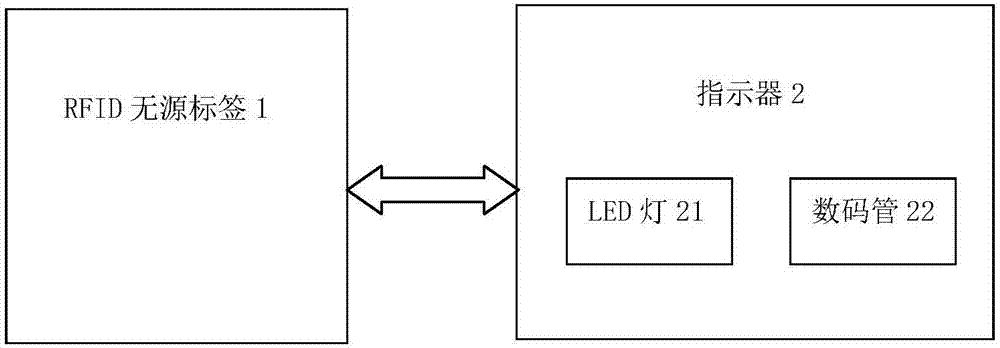

[0090] Such as image 3 As shown, the reminder device in the above-mentioned picking system includes: an RFID passive tag 1 and an indicator 2 connected to the RFID passive tag 1, and the RFID passive tag 1 is used to control the display of the indicator 2 in response to an external wireless signal . The indicator 2 includes an LED light 21 and a digital tube 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com