Drive circuit with power factor correction used for LED street lamp

A technology for power factor correction and LED street lamps, applied in the field of LED driving, can solve problems such as multiple peripheral devices, and achieve the effects of high lighting efficiency, low manufacturing cost and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

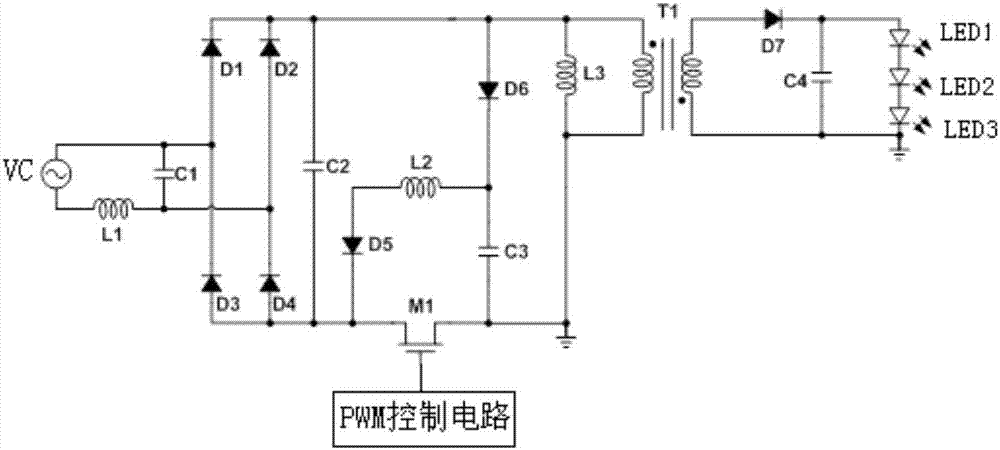

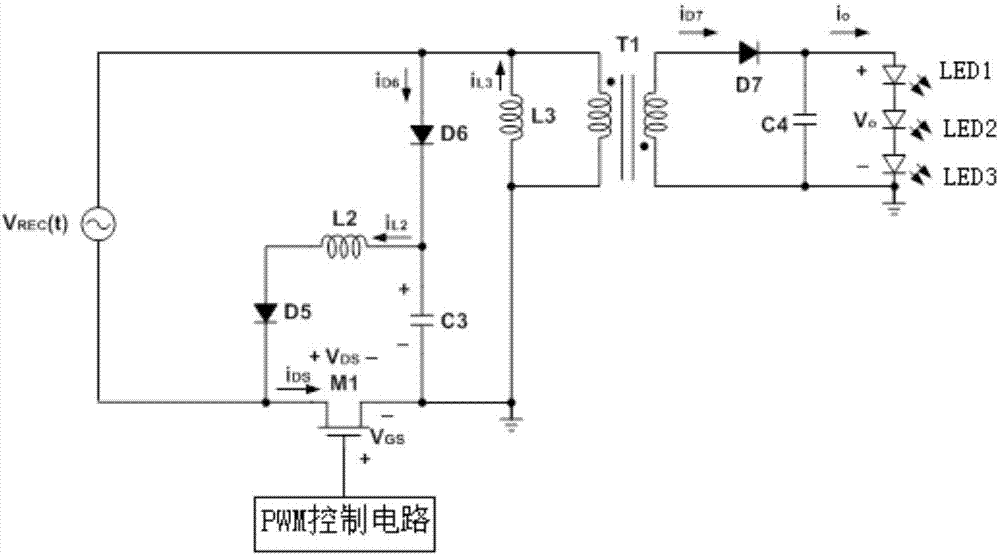

[0018] Please refer to figure 1 , the drive circuit with power factor correction for LED street lamps of the present invention includes an AC power supply, a full-bridge rectifier circuit, a primary control circuit, an energy transmission circuit and a secondary output rectifier circuit, and the full-bridge rectifier circuit includes a first diode D1 , the second diode D2, the third diode D3 and the fourth diode D4, the primary control circuit includes the fifth diode D5, the sixth diode D6, the second inductor L2, the third capacitor C3 and The power switch tube M1, the energy transmission circuit includes a third inductor L3 and a transformer T1, and the secondary output rectification circuit includes a seventh diode D7.

[0019] The anode of the first diode D1 and the cathode of the third diode D3 are connected to one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com