Tipping plow

A technology of overturning plow and overturning frame, applied in the field of overturning plow, can solve the problems of high power, easy damage to the plough share by roots and inconvenience, etc., and achieves the requirements of reducing horsepower, avoiding damage to the plough share, and ensuring stable and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

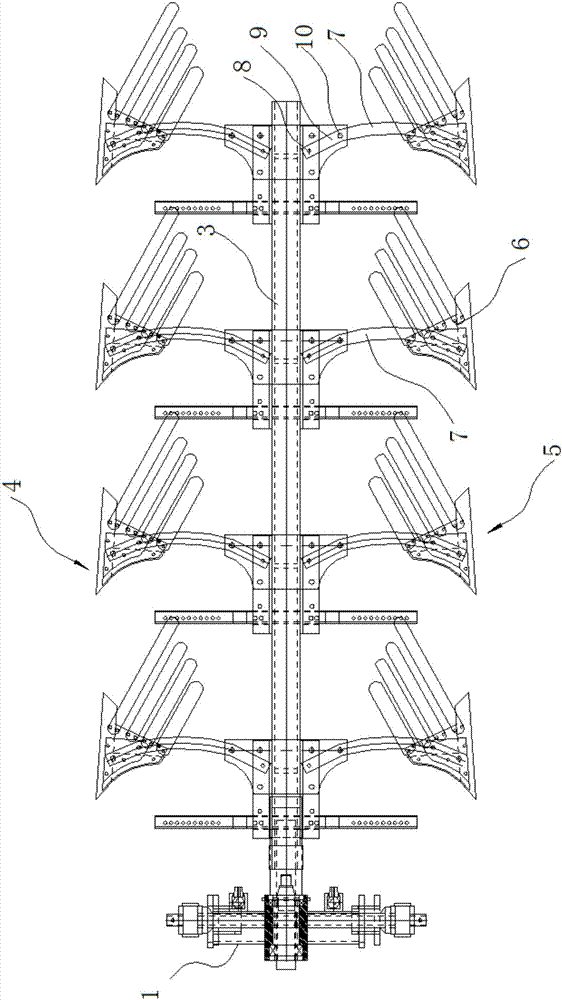

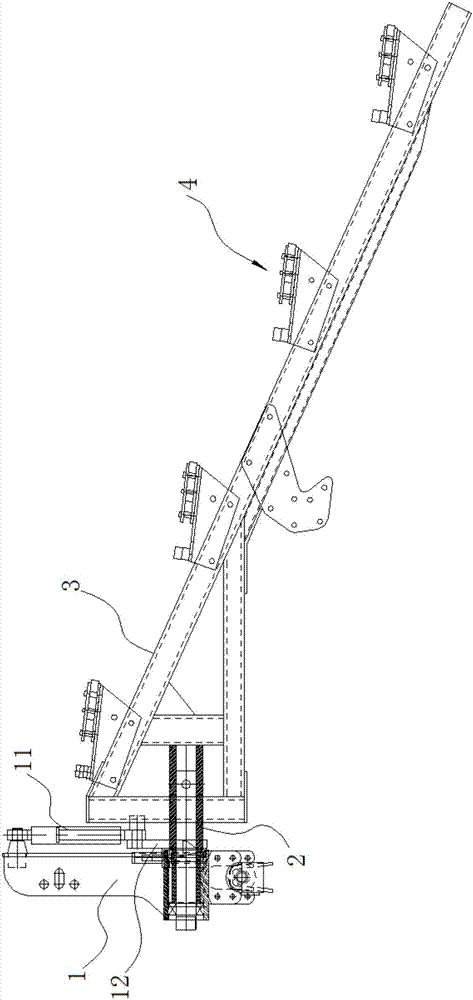

[0014] Such as figure 1 with figure 2 As shown, a kind of overturning plow comprises a suspension frame 1 connected with a tractor, a rotating shaft 2 is rotatably installed on the suspension frame 1, a turning frame 3 is fixedly installed on the rotating shaft 2, the suspension frame 1 and the rotating shaft 2 is provided with a turning drive device, along the length direction of the turning frame 3, the turning frame 3 is provided with an upper plowshare 4 and a lower plowshare 5 which are mutually symmetrical with respect to the length direction of the turning frame 3. The shapes and angles of the upper ploughshare 4 and the lower ploughshare 5 are mutually symmetrical with respect to the length direction of the turning frame 3, the suspension frame 1 is installed behind the tractor, and a straight line perpendicular to the line connecting the two rear wheels of the tractor passes through the turning frame 3 in the middle of the length direction. This can effectively red...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap