Aggregate dryer burner device and method

A burner, main combustion technology, applied in burners, combustion equipment, non-progressive dryers, etc., can solve the problem of ineffective combustion of heavy oil, and achieve the effect of reducing requirements, saving costs, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

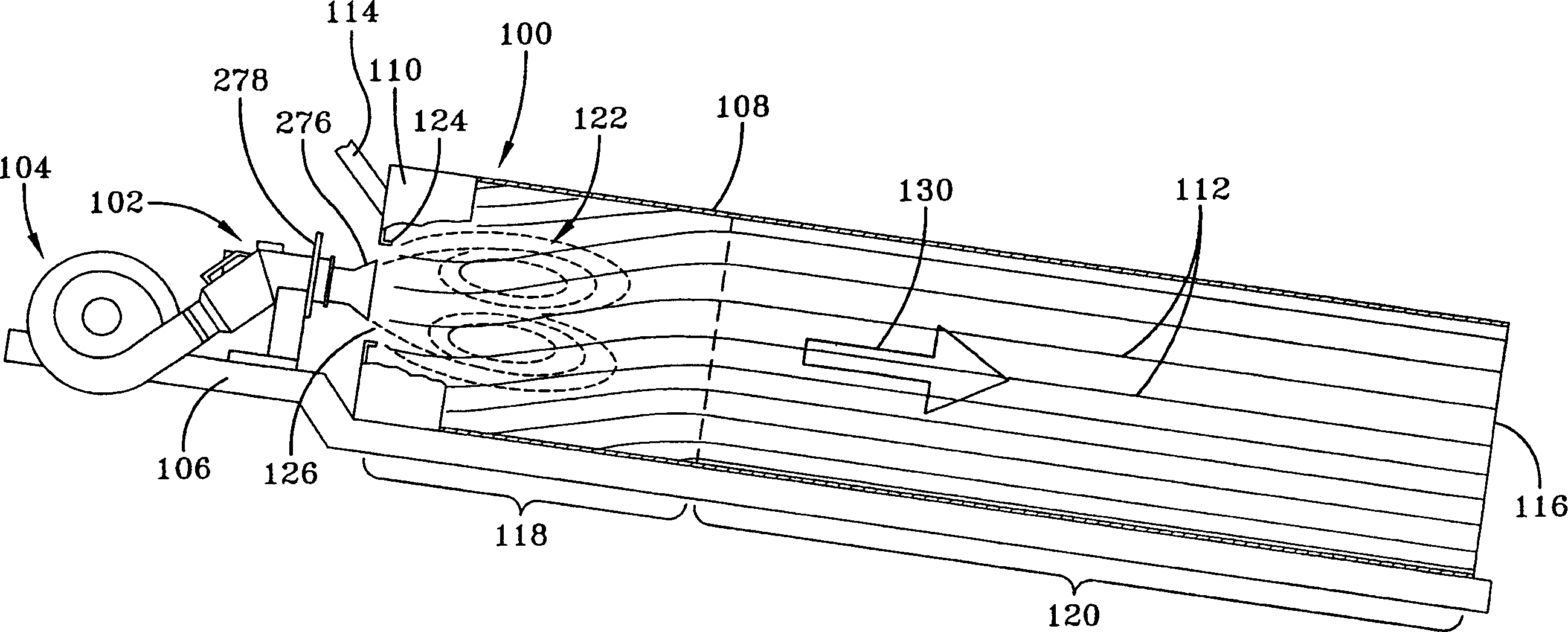

[0028] figure 1 A portable rotary stock drier 100 for drying and preheating stock mixed with petroleum-based materials in the manufacture of paving asphalt is schematically shown, heated by the burner of the present invention. The dryer 100 is heated by a burner 102 which includes a main combustion air supply such as a centrifugal blower 104 for supplying combustion air to the burner. Other types of primary combustion air supplies are readily available and are known in the art. The blower preferably produces air at a pressure in the range of approximately 22 osig to 28 osig. In the most preferred embodiment, the blower produces air at a pressure of approximately 24 osig. The dryer 100 , burner 102 and blower 104 are mounted on a suitable frame 106 .

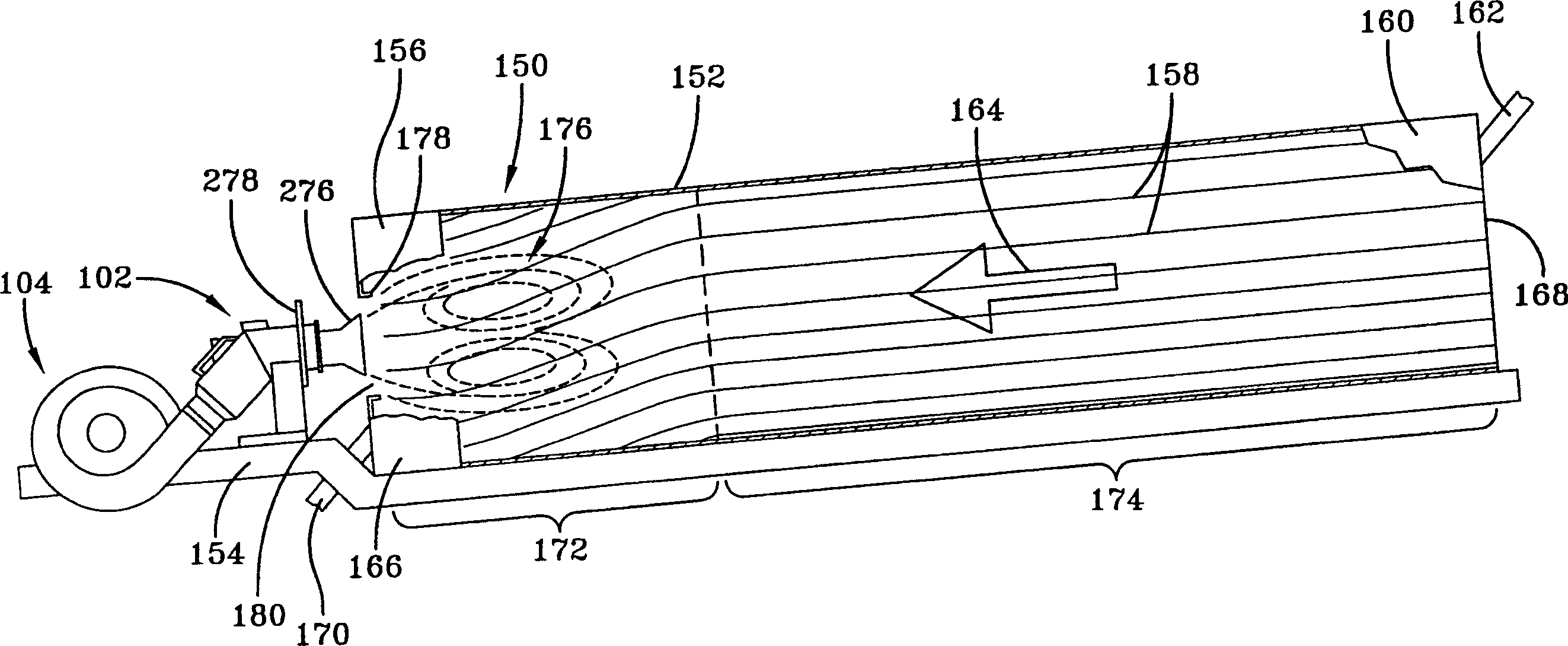

[0029] figure 2 Another portable rotary stockpile dryer, countercurrent dryer 150, for drying and preheating stockpile mixed with petroleum-based materials in the manufacture of paving asphalt, is schematically shown, heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com