Heat-resistant fuel-activating substance

a fuel-activating substance and heat-resistant technology, applied in the direction of fuels, liquid carbonaceous fuels, lighting and heating apparatus, etc., can solve the problems of no significant effect that enables an improvement in combustion efficiency, and achieve stable combustion flame, increase flame temperature, and reduce the amount of fuel use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

(1) Test Results in Boiler

[0079]The above heat-resistant fuel-activating substance was affixed in a specific boiler and the energy saving efficiency was verified. Herein, the “energy saving efficiency” was defined as follows.

[0080]First, a coefficient obtained by dividing the amount of fuel (unit: liter in the case of liquid fuel, m3 in the case of gas fuel) used during the test by the amount of water (unit: m3) used to obtain steam before affixing of the heat-resistant fuel-activating substance was defined as a “fuel use coefficient before affixing” (Eb).

[0081]On the other hand, a coefficient obtained by dividing the amount of fuel used during the test by the amount of water used to obtain steam after affixing of the heat-resistant fuel-activating substance is similarly defined as a “fuel use coefficient after affixing” (Ea).

[0082]Then, an energy saving ratio (η) is defined by the following equation:

η=(Eb−Ea) / Eb×100.

[0083]That is, a ratio (%) of a decrease in amount before and afte...

first embodiment

(1-1) First Embodiment

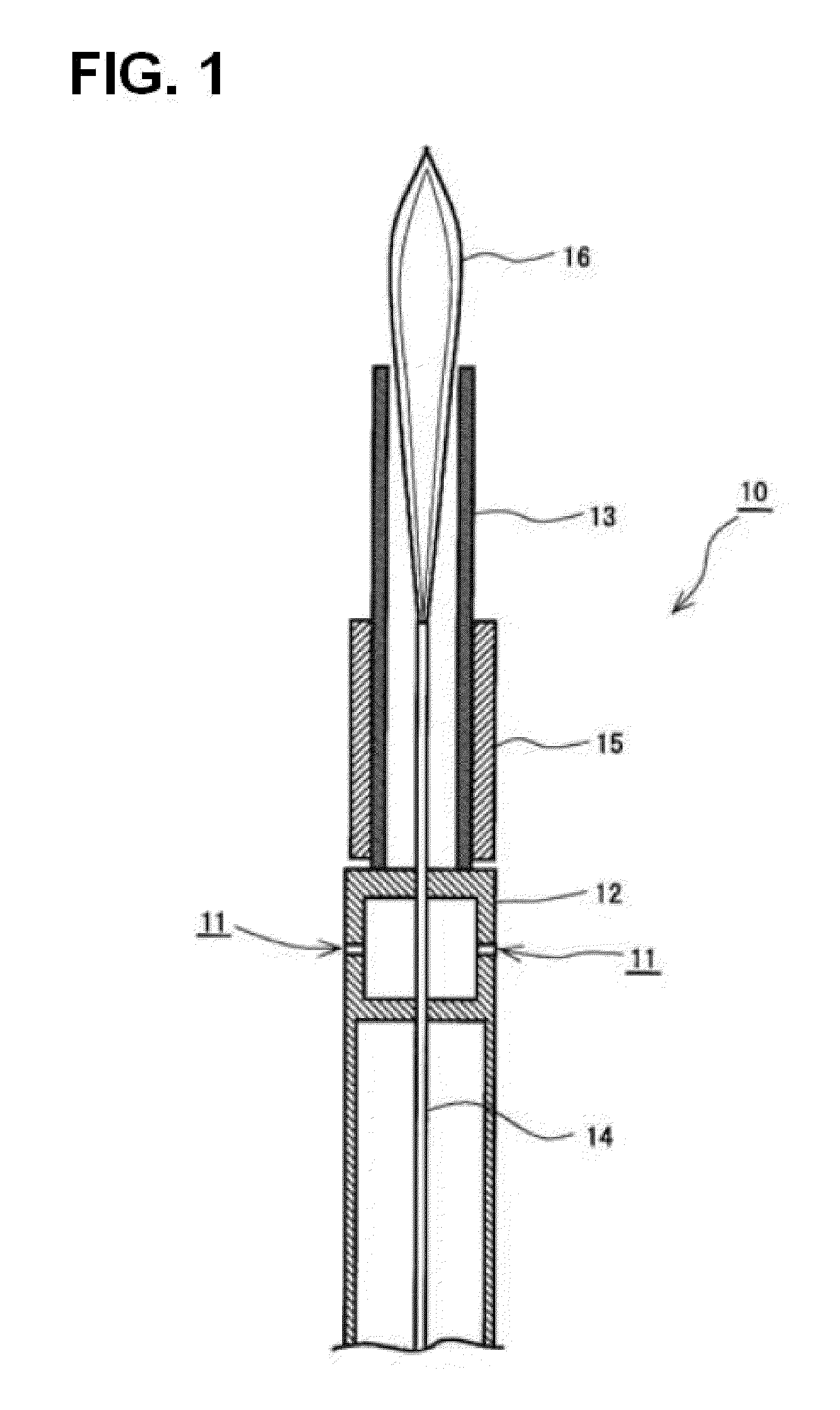

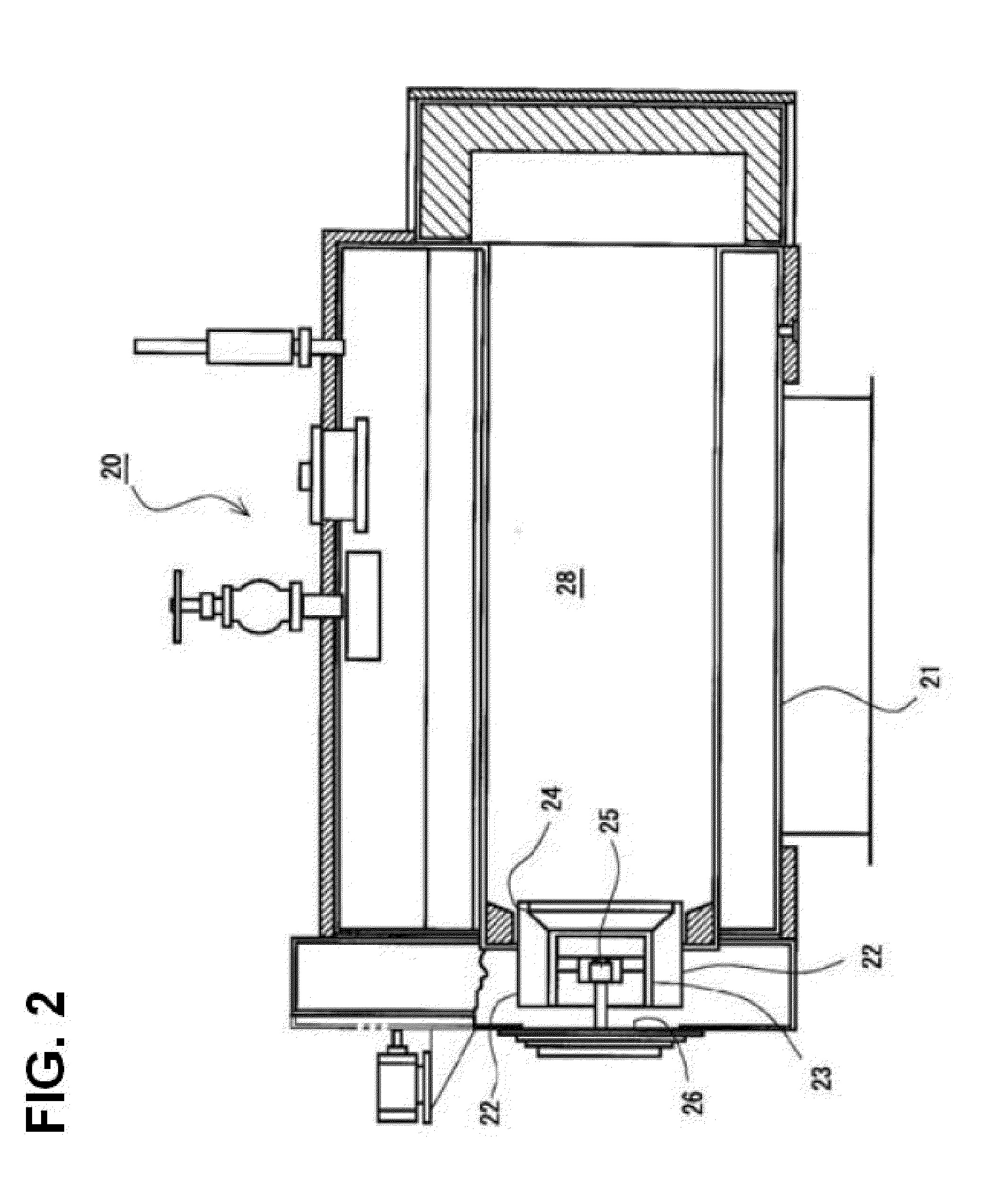

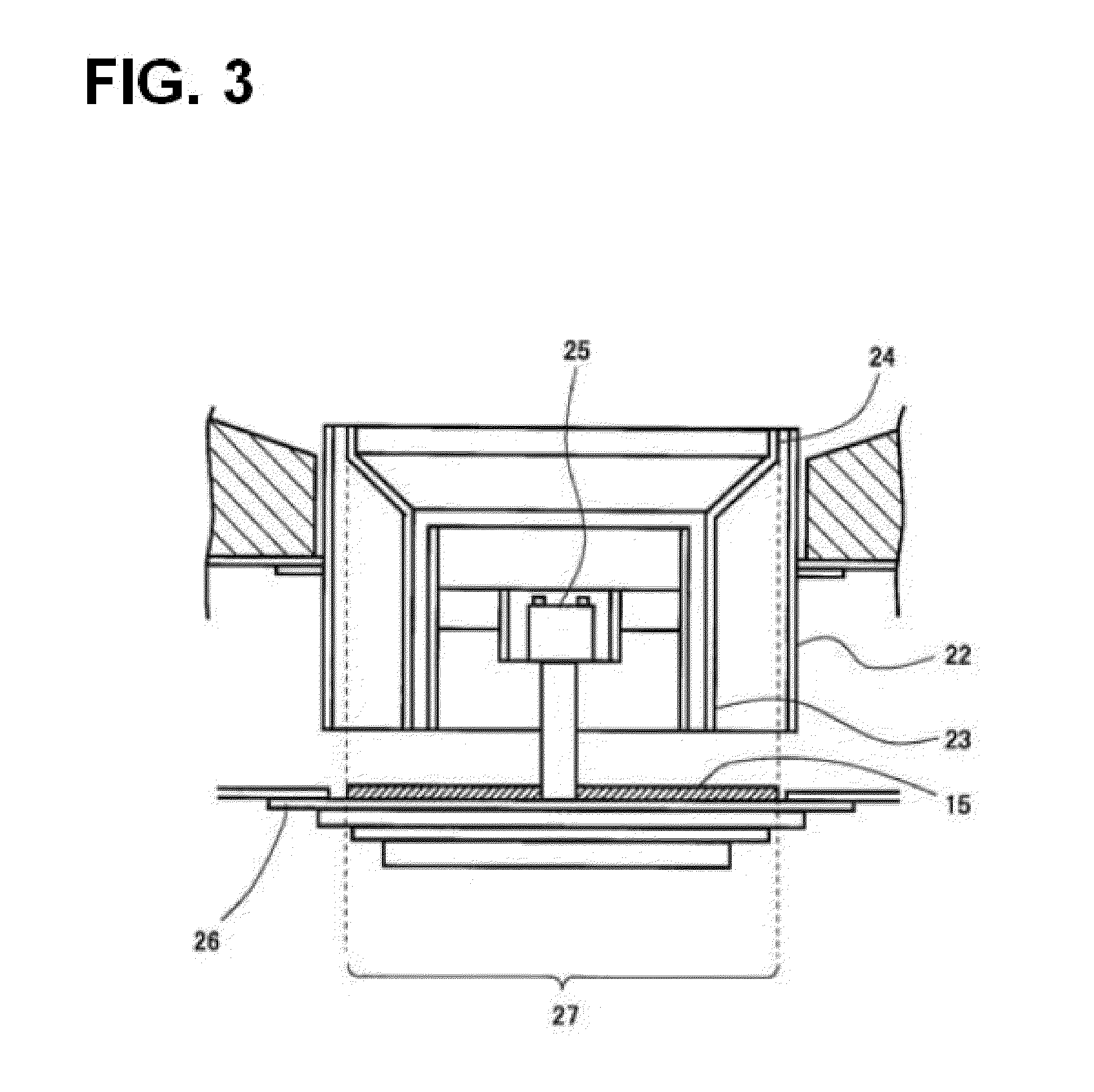

[0085]As the first embodiment, verification was conducted using a flame-tube smoke-tube boiler as a specific boiler. The fuel used in this flame-tube smoke-tube boiler (KMS-16A, IHI PACKAGED BOILER CO., LTD.) was A-heavy oil, the burner used was a gun type burner, the boiler capacity was 8,000 kg / h, and the control method was a proportional control method. FIG. 2 is a schematic view of the flame-tube smoke-tube boiler 20, and FIG. 3 enlarges a gun type burner portion thereof. A combustion device 22 was attached to one end (left end in FIG. 2) of a combustion chamber 28 in a boiler body 21, and a combustion cone 23 enabled a cone maximum diameter portion 24 having the maximum outer diameter to open toward inside the boiler body 21 (rightward in FIG. 2, upward in FIG. 3), and emitted flame from the tip of gun type burner 25 located in almost the shaft center to a center direction of a combustion chamber 28. A flange 26 that fixed the gun type burner 25 was provid...

second embodiment

(1-2) Second Embodiment

[0087]As the second embodiment, verification was conducted using a once-through boiler as a specific boiler. The fuel used in this once-through boiler (STE2001GLM, Nippon Thermoener Co., Ltd.) was LPG, the burner used was a gun type burner, the boiler capacity was 1,667 kg / h, and the control method was a 3-position control method. FIG. 4 is a schematic view of the once-through boiler 30, and FIG. 5 enlarges a gun type burner portion thereof. A combustion device 32 was attached to one end (upper end in FIG. 4) of a combustion chamber 38 in a boiler body 31, and a combustion cone 33 enabled a cone maximum diameter portion 34 having the maximum outer diameter to open toward inside the boiler body 31 (downward in FIG. 4 and FIG. 5), and emitted flame from the tip of gun type burner 35 located in almost the shaft center to a center direction of a combustion chamber 38. A flange 36 that fixed the gun type burner 35 was provided at the rear end of the combustion devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| spectral emissivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com