Labor-saving pressure rebound mechanism for furniture

A rebound mechanism and furniture technology, applied in furniture parts, home appliances, applications, etc., can solve problems such as affecting user experience and inappropriate use by users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

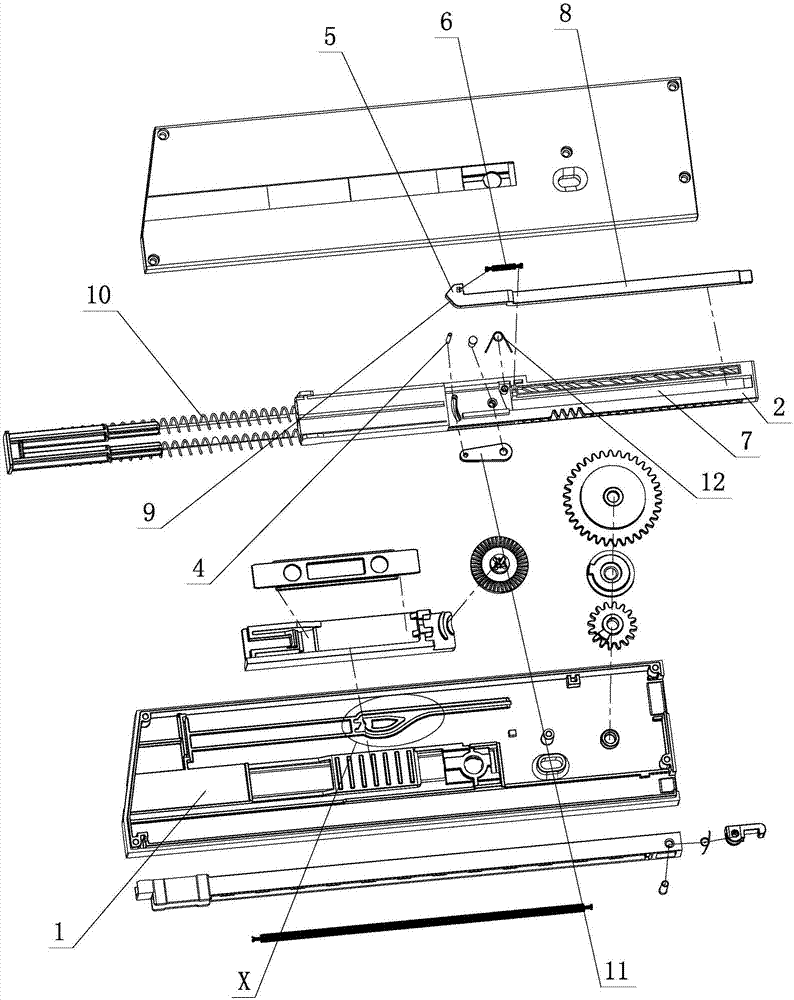

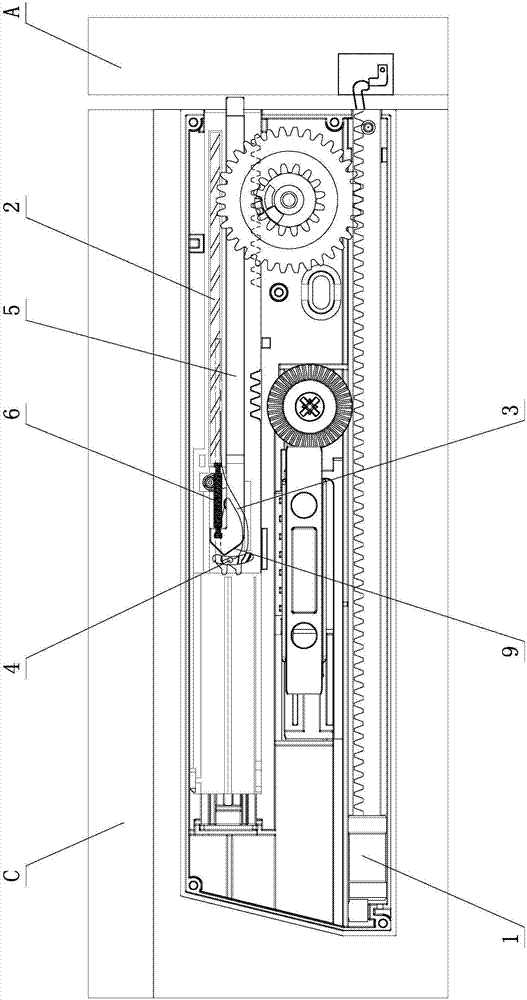

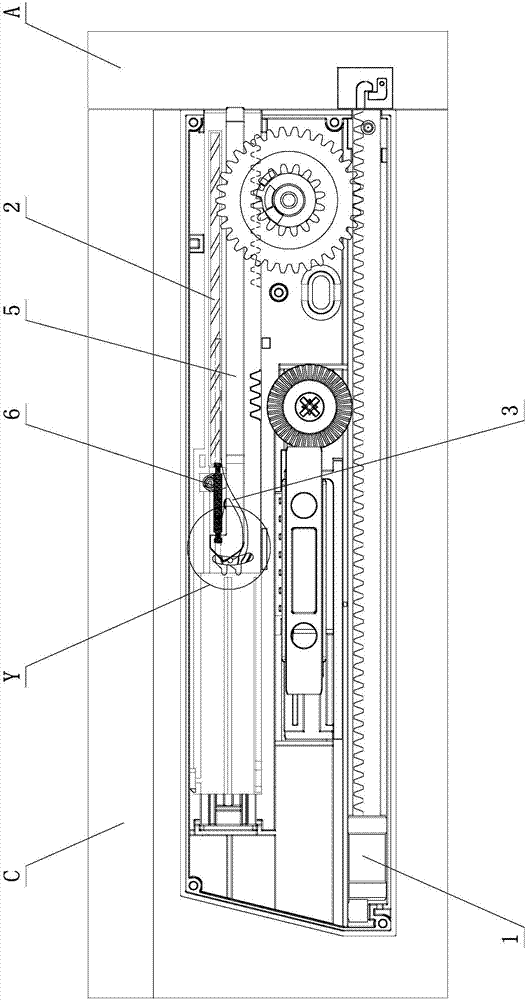

[0021] see Figure 1-Figure 8 , the furniture uses a labor-saving push rebound mechanism, including a push rebound device. The push rebound device at least includes a rebound bracket 1 and a push element 2. The push element 2 is positioned and / or slid on the bounce bracket 1, and the bounce bracket 1 is provided with a heart-shaped chute. 3. The sliding part 4 and the sliding element 5 are arranged on the pushing element 2, and the sliding element 5 is slidably arranged on the pushing element 2; Acting on the sliding part 4 , the sliding part 4 slides along the track of the heart-shaped chute 3 in a sequential direction, and drives the pushing element 2 to slide on the rebound bracket 1 .

[0022] Further speaking, the sliding element 5 and the sliding part 4 rely on each other or form a certain gap.

[0023] Further, a return spring 6 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com