Multifunctional reeling-off equipment

A multifunctional and equipment technology, applied in the field of fire extinguishing, rescue and escape equipment outside the building, can solve the problems of complex structure, affecting the speed and efficiency of rescue and fire extinguishing, and the fire hydrant door being blocked by residents with sundries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

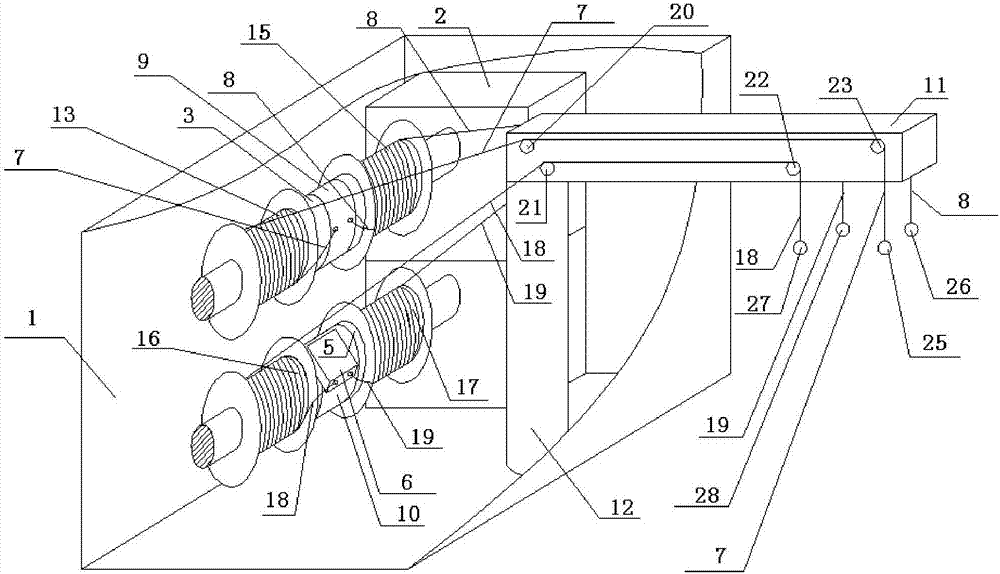

[0074] like figure 1 shown, figure 1It is a schematic oblique view of the multifunctional rope releasing device according to the first embodiment of the present application. The multifunctional rope-releasing equipment includes a housing 1, a motor 2, a rotating shaft 3, a rotating shaft 5, a slow descender 6, a pull rope 7, a pull rope 8, a rotating body 9, a rotating body 10, a cantilever 11, and a column 12, Above-mentioned electric motor 2, rotating shaft 3, rotating shaft 5, descender 6, stay cord 7, stay cord 8, rotating body 9, rotating body 10, column 12 are arranged in the casing, and motor 2 and rotating shaft 3, rotating shaft 5 The connection can drive the rotating shaft 3 and the rotating shaft 5 to rotate. The above-mentioned rotating body 9 is sleeved on the outer circumference of the rotating shaft 3 and can rotate in one direction around the rotating shaft 3. The above-mentioned rotating body 10 is sleeved on the outer circumference of the rotating shaft 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com