Chemical teaching instrument dusting and drying device

A drying device and instrument technology, applied in chemical instruments and methods, drying gas arrangement, drying, etc., can solve the problems of ineffective dust removal, slow drying speed, incomplete dust removal, etc., and achieve fast drying speed , clean thoroughly, avoid the effect of being too wet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

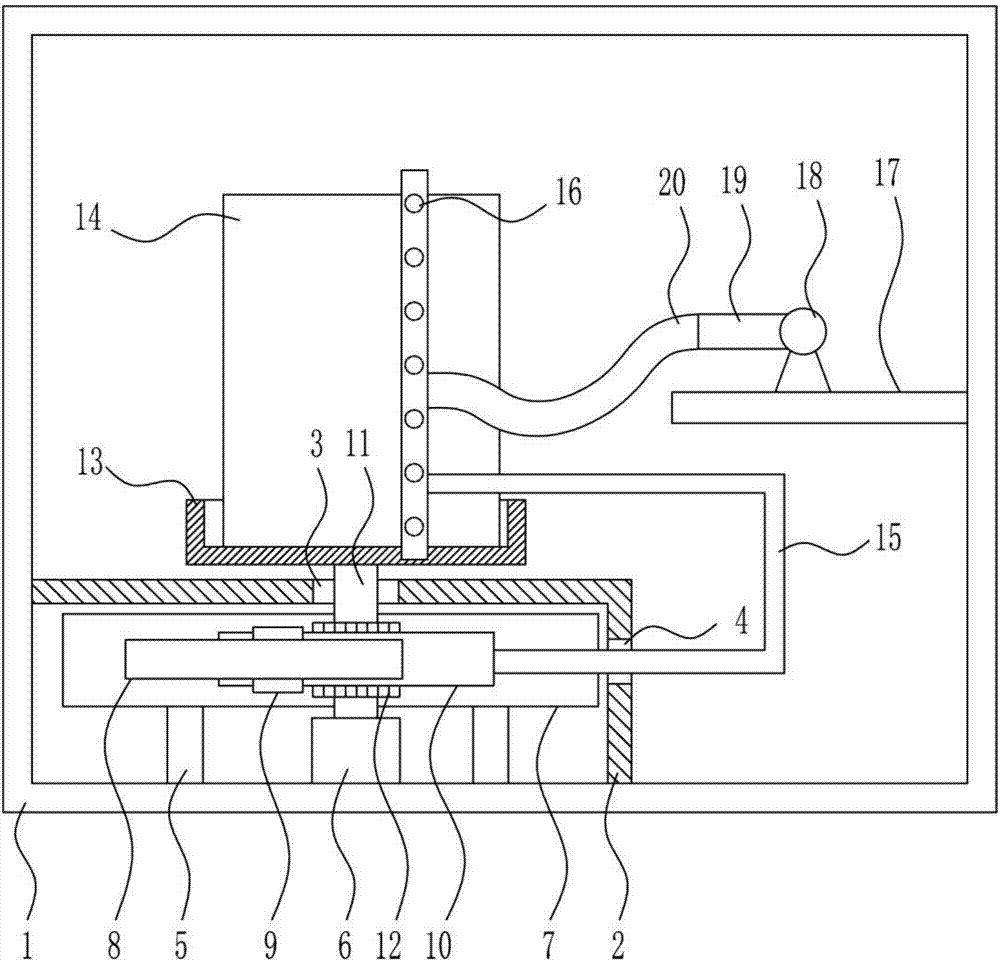

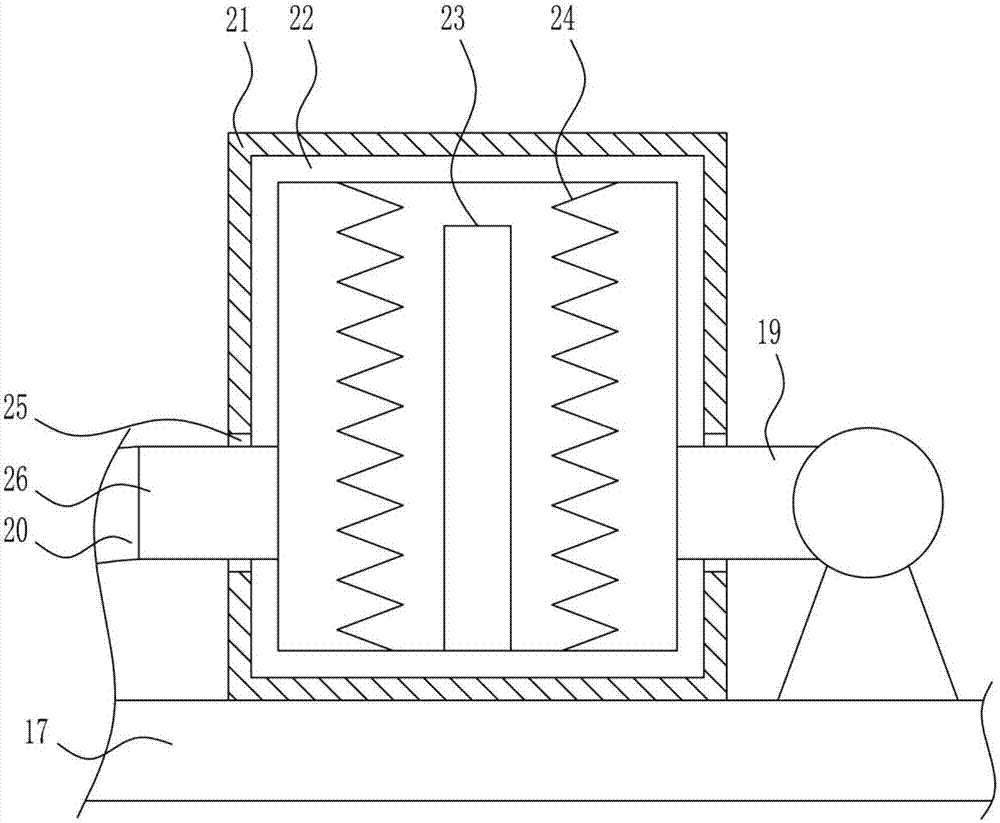

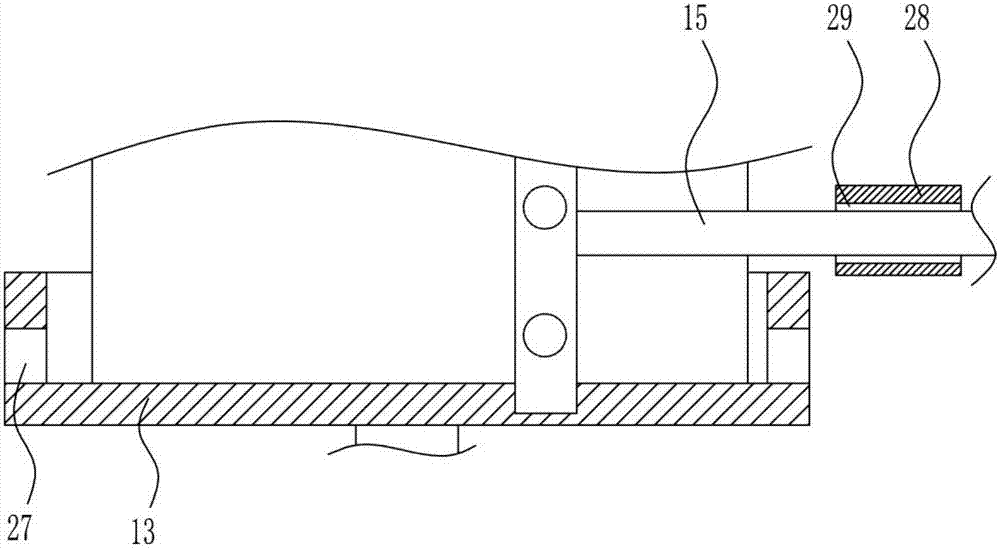

[0021] A chemical teaching instrument dust removal and drying device, such as Figure 1-3 As shown, it includes a box body 1, a casing 2, a bracket 5, a motor 6, a first casing 7, a slide rail 8, a slider 9, a rack 10, a rotating shaft 11, a sector gear 12, a placement frame 13, and a connecting rod 15 , blowing pipe 16, fixed plate 17, blower fan 18, first air outlet pipe 19 and flexible pipe 20, casing 1 is provided with casing 2 on the left side of the inner lower wall, and the top of casing 2 has first through hole 3, casing 2 Right wall has guide hole 4, is provided with support 5 and motor 6 in box body 1 inner lower wall inner left shell 2, support 5 is positioned at the left and right sides of motor 6, and support 5 upper end is provided with first housing 7, the first The inner sides of the front and rear walls of the housing 7 are provided with slide rails 8, on which slide rails 8 are slidably connected with sliders 9, on which sliders 9 are provided with racks 10, ...

Embodiment 2

[0023] A chemical teaching instrument dust removal and drying device, such as Figure 1-3 As shown, it includes a box body 1, a casing 2, a bracket 5, a motor 6, a first casing 7, a slide rail 8, a slider 9, a rack 10, a rotating shaft 11, a sector gear 12, a placement frame 13, and a connecting rod 15 , blowing pipe 16, fixed plate 17, blower fan 18, first air outlet pipe 19 and flexible pipe 20, casing 1 is provided with casing 2 on the left side of the inner lower wall, and the top of casing 2 has first through hole 3, casing 2 Right wall has guide hole 4, is provided with support 5 and motor 6 in box body 1 inner lower wall inner left shell 2, support 5 is positioned at the left and right sides of motor 6, and support 5 upper end is provided with first housing 7, the first The inner sides of the front and rear walls of the housing 7 are provided with slide rails 8, on which slide rails 8 are slidably connected with sliders 9, on which sliders 9 are provided with racks 10, ...

Embodiment 3

[0026] A chemical teaching instrument dust removal and drying device, such as Figure 1-3 As shown, it includes a box body 1, a casing 2, a bracket 5, a motor 6, a first casing 7, a slide rail 8, a slider 9, a rack 10, a rotating shaft 11, a sector gear 12, a placement frame 13, and a connecting rod 15 , blowing pipe 16, fixed plate 17, blower fan 18, first air outlet pipe 19 and flexible pipe 20, casing 1 is provided with casing 2 on the left side of the inner lower wall, and the top of casing 2 has first through hole 3, casing 2 Right wall has guide hole 4, is provided with support 5 and motor 6 in box body 1 inner lower wall inner left shell 2, support 5 is positioned at the left and right sides of motor 6, and support 5 upper end is provided with first housing 7, the first The inner sides of the front and rear walls of the housing 7 are provided with slide rails 8, on which slide rails 8 are slidably connected with sliders 9, on which sliders 9 are provided with racks 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com