Automatic cable take-up and pay-off device of nuclear power plant underwater mobile robot

A mobile robot and automatic retractable technology, which is applied in the field of nuclear power testing equipment, can solve problems such as movement obstruction, high labor intensity, and affecting positioning accuracy, and achieve the effects of reducing radioactive dose levels, reducing labor intensity, and streamlining mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

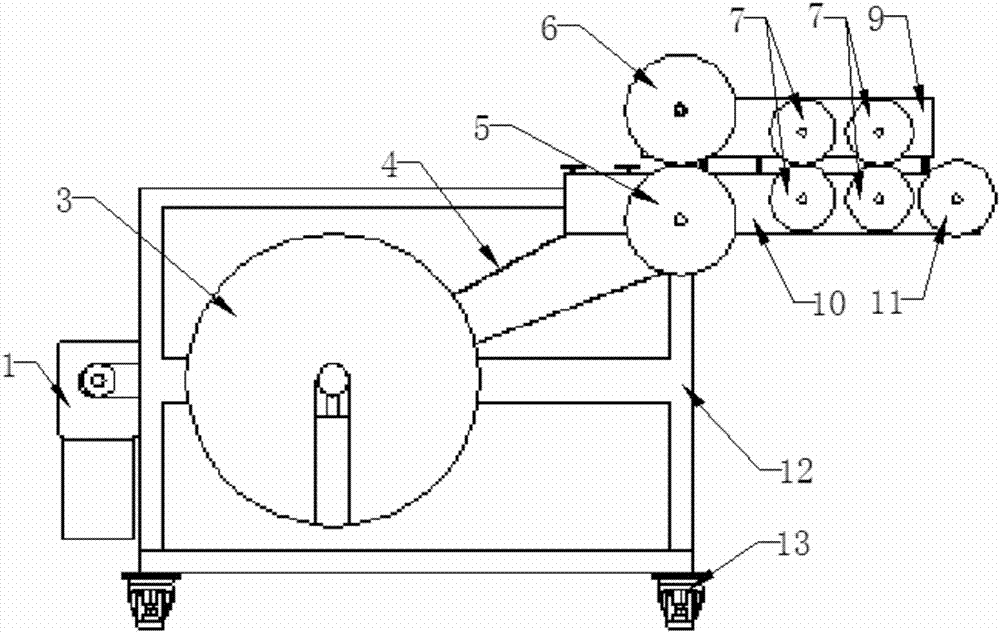

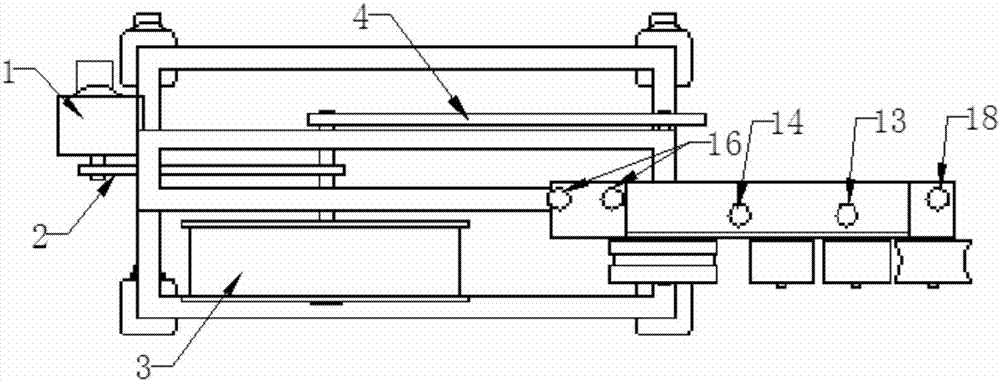

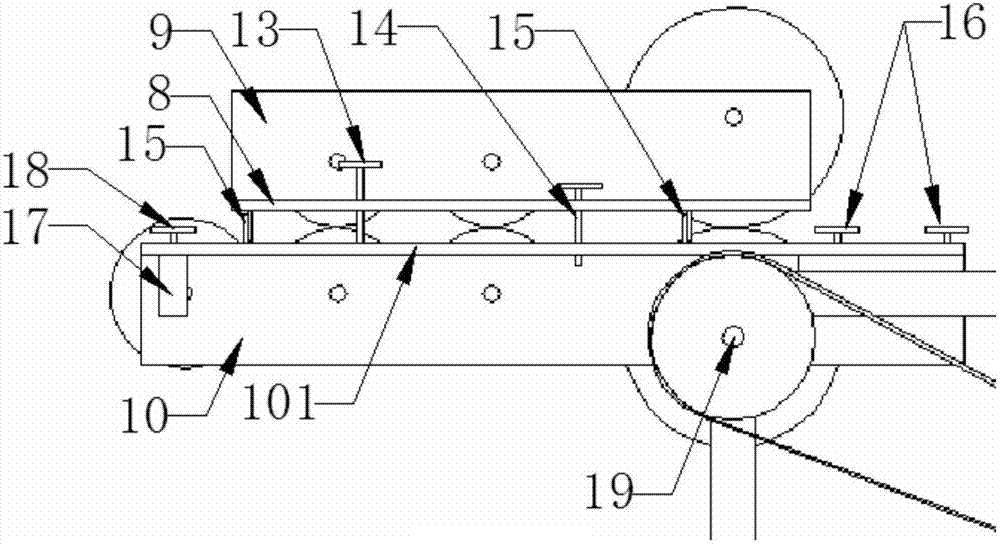

[0020] Such as figure 1 , 2 , 3, 4, and 5, the cable automatic retracting device of the nuclear power plant underwater mobile robot includes a frame 12; the take-up roller 3, cable introduction mechanism, caster 131 and drive mechanism installed on the frame 12 .

[0021] The cable introduction mechanism includes a first rotating shaft 19 rotatably connected to the frame 12, a support plate connected to the first rotating shaft 19, at least one pair of pressing rollers 6 mounted on the support plate , At least one pair of decontamination rollers 7 installed on the support plate and at least one introduction roller 11 installed on the support plate, the peripheral surface of which is concave in an elliptical arc shape. In this embodiment, there is a pair of pinch rollers 6, two pairs of decontamination rollers 7, the axes of the intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com