Transverse overall movement device for support and construction method thereof

A translation device and construction method technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of serious wear of Bailey beams, difficult brackets, and high safety risks, avoiding disassembly and re-installation, and improving construction efficiency. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

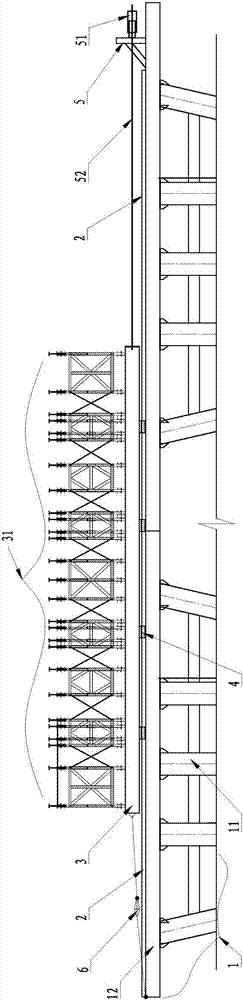

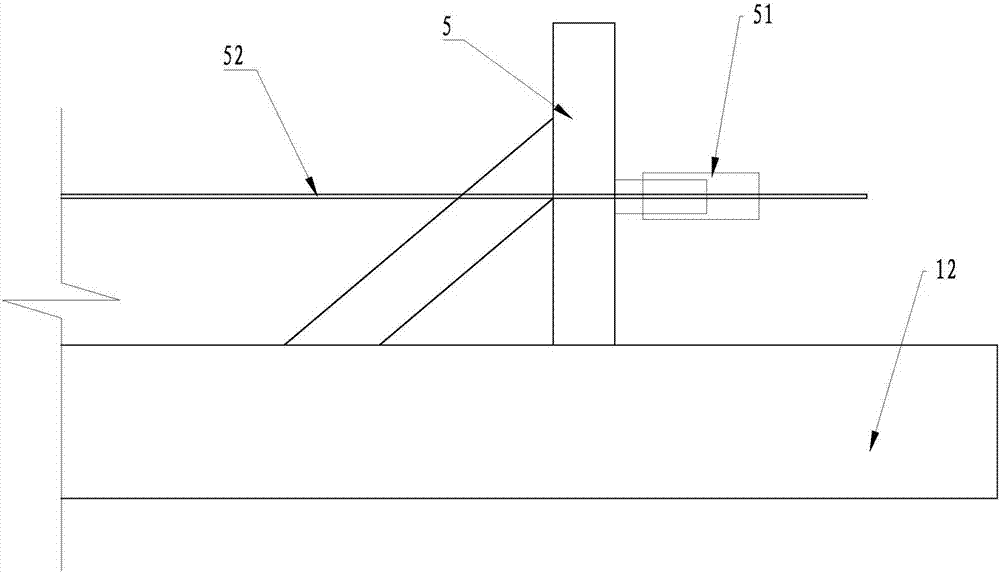

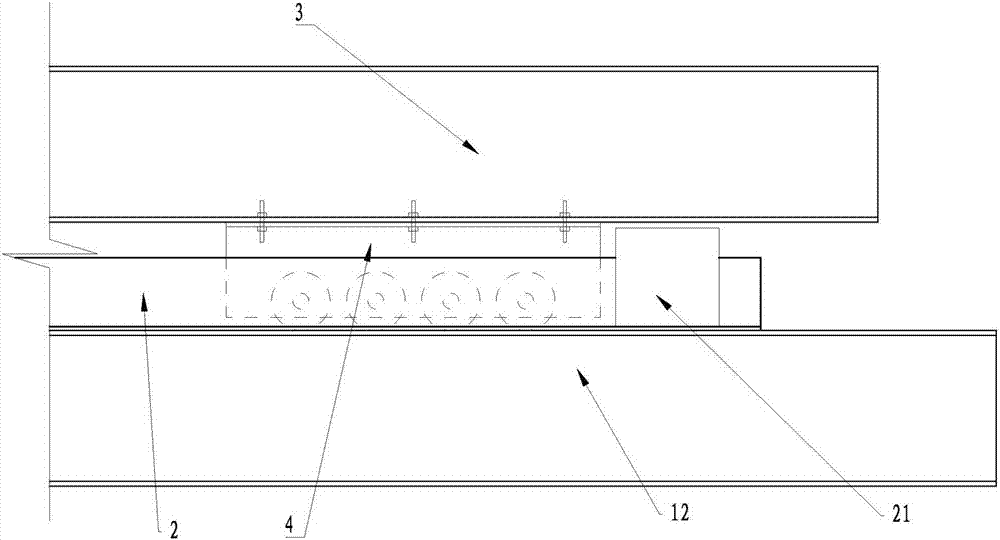

[0042] The specific embodiment of the present invention sees Figure 1-6 :

[0043] The present invention mainly discloses a support horizontal overall translation device and its construction method. Some simple connection methods and structures are well known to those skilled in the art, so they will not be described in detail. The structural diagrams related to the features of the present invention are not and need not be completely drawn according to the actual size, and will be described first.

[0044] A kind of bracket lateral overall translation device, such as Figure 1-6 , including a carrier frame 1, and also includes a support beam 3 sliding on the carrier frame 1 and above which a bracket 31 to be translated is fixed, a sliding track 2 is fixed on the carrier frame 1, and the sliding track 2 has a plurality of Evenly distributed installation gaps, each of the installation gaps is equipped with a detachable interlocking rail 8 or a supporting sand cylinder 9, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com