Ventilation fan for degreasing

A ventilation fan and fan blade technology, applied in the field of ventilation fans, can solve problems that affect people's health, unclean cleaning, complicated operation, etc., and achieve the effects of saving manpower, increasing cleaning time, and increasing time for oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

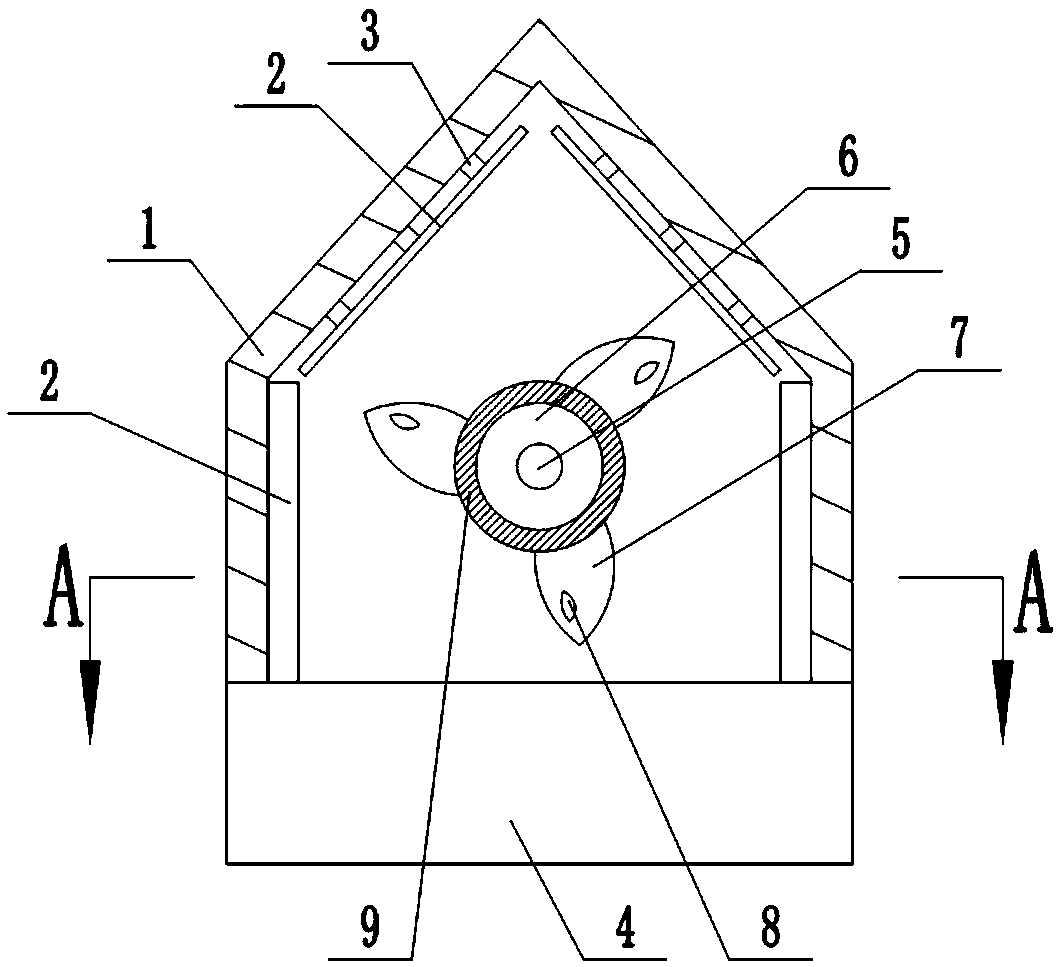

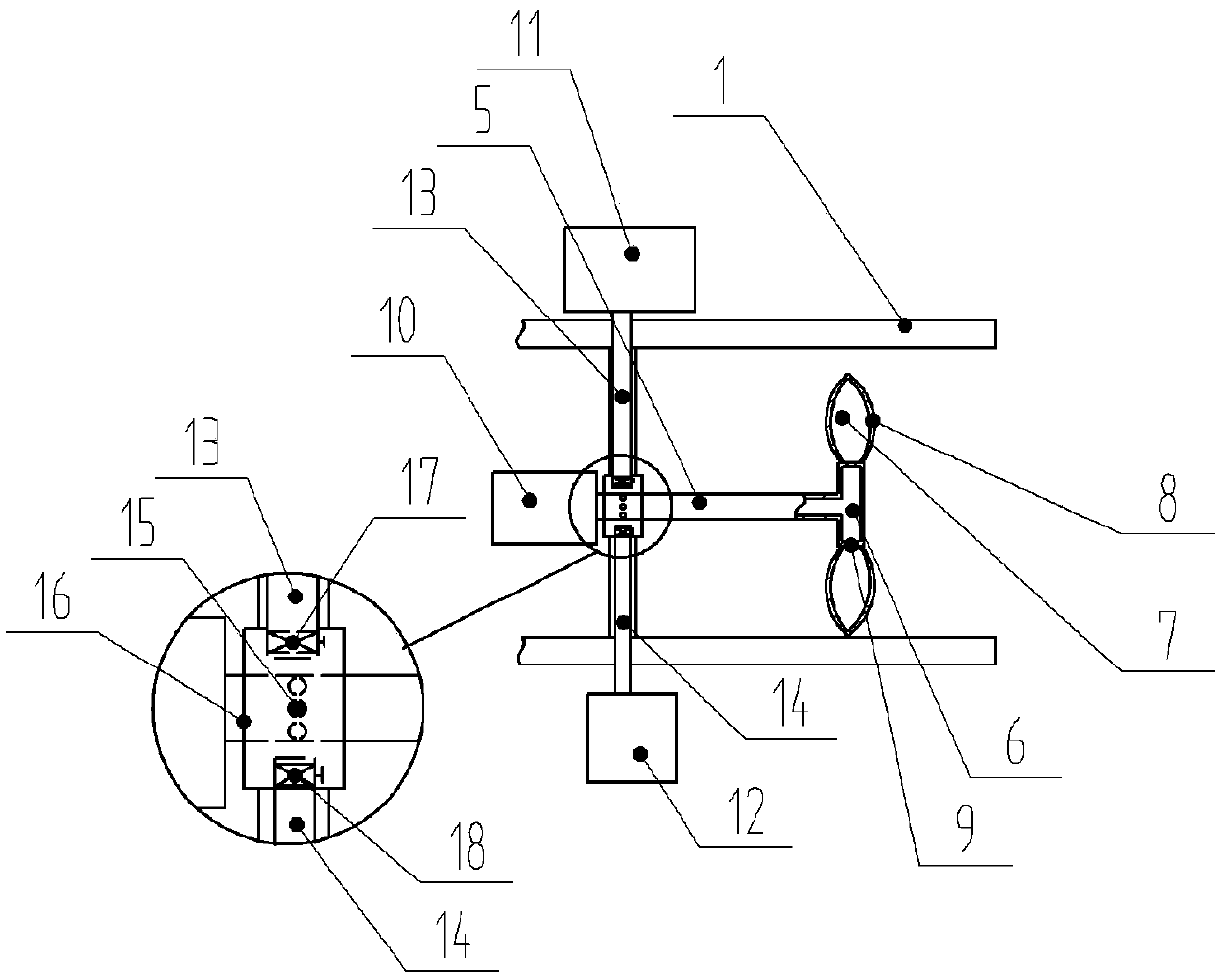

[0021] The reference signs in the drawings of the description include: housing 1, drainage plate 2, connecting column 3, collection tank 4, rotating shaft 5, flow tank 6, fan blade 7, oil inlet hole 8, water outlet hole 9, motor 10, the first A water tank 11, a second water tank 12, a first delivery pipe 13, a second delivery pipe 14, a water inlet 15, a fixed cover 16, a first valve 17, and a second valve 18.

[0022] Explanation: The up, down, left, and right sides or ends in the embodiments are subject to the up, down, left, and right sides or up, down, left, and right ends of the attached drawings.

[0023] The embodiment is basically as attached figure 1 Shown: the ventilation fan used to remove oil, including a prismatic shell 1, a prismatic through hole is opened in the center of the shell 1, drainage pipes are arranged on both sides of the shell 1, and a Six connecting colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com