Water pipe gasket assembly equipment

A technology for assembling equipment and gaskets, applied in the field of manufacturing and processing, can solve the problems of labor consumption, low production capacity, low utilization rate of personnel, etc., and achieve the effects of saving labor costs, reducing production costs, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

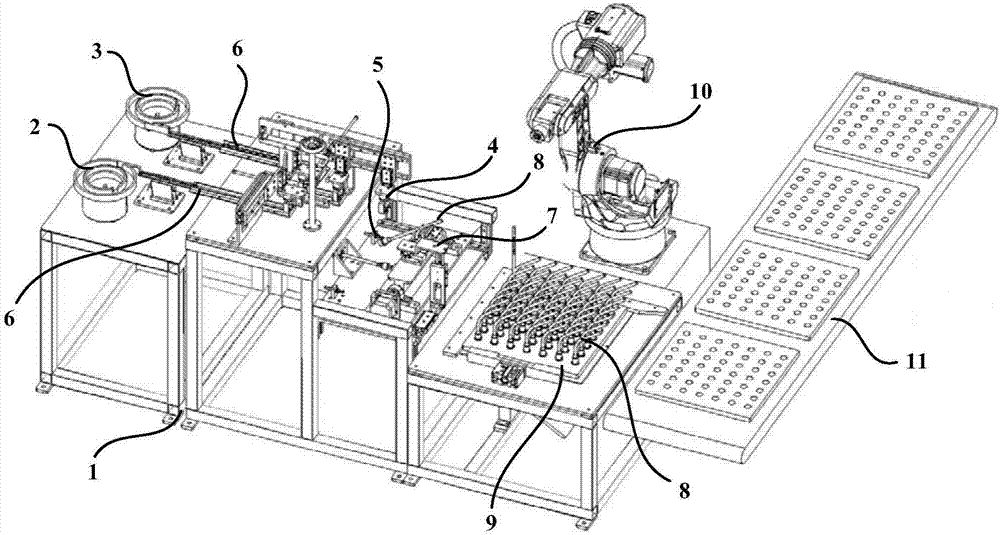

[0034] In order to improve the assembly efficiency of the water pipe sealing gasket, reduce the production cost and the use of human resources. An embodiment of the present invention provides a water pipe sealing gasket assembly equipment. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

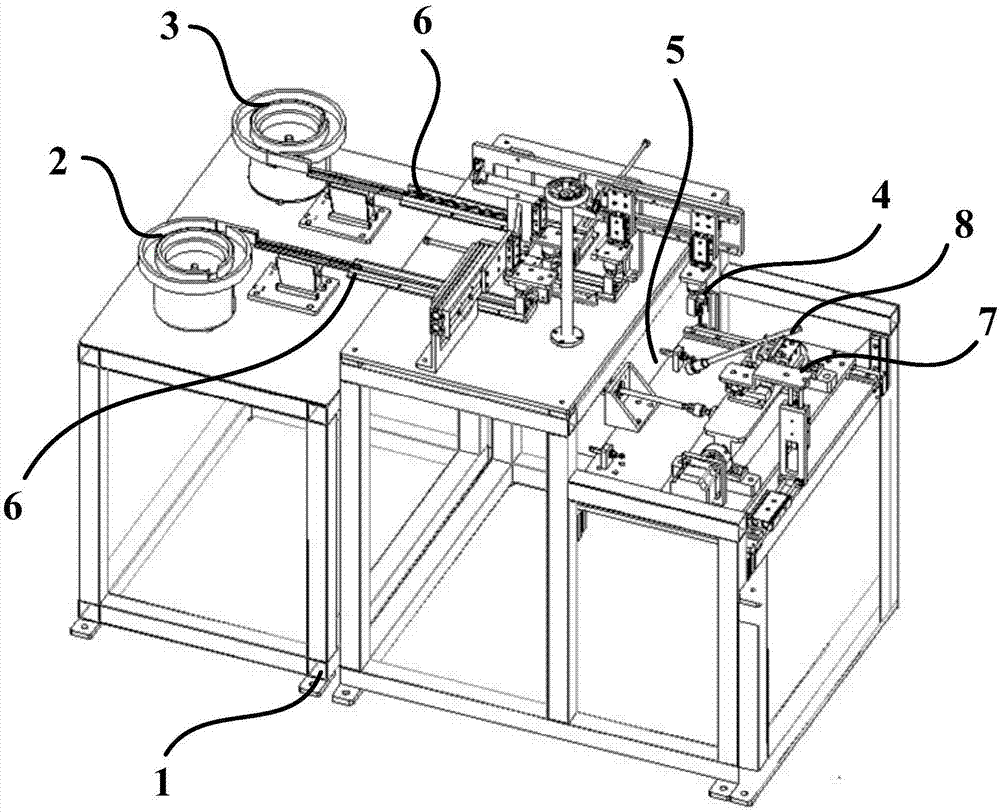

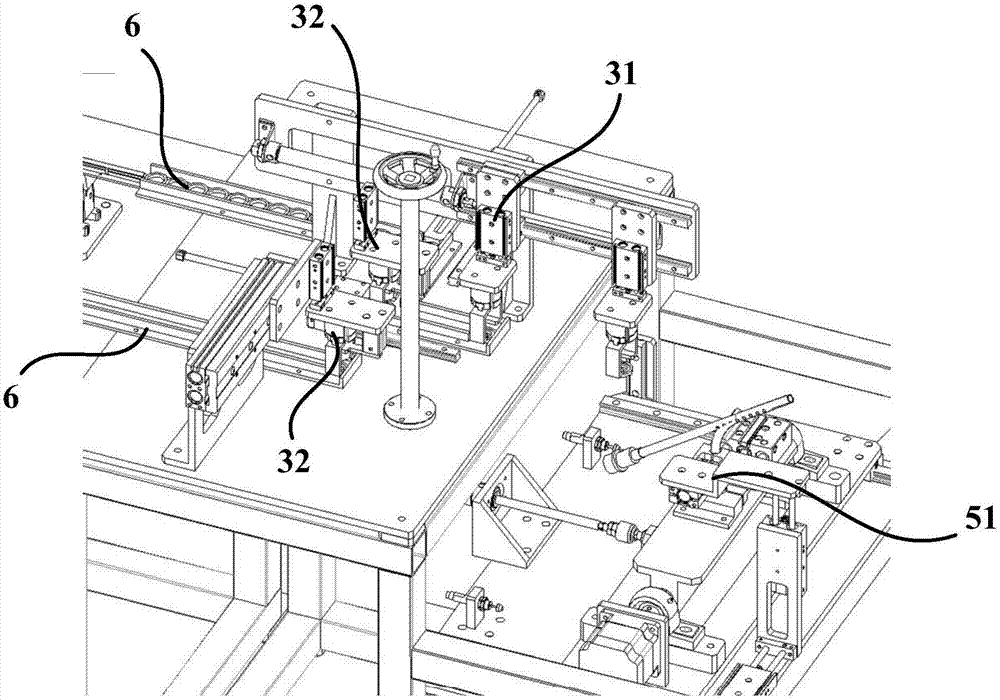

[0035] refer to figure 1 , the water pipe gasket assembly equipment provided by an embodiment of the present invention includes a carrier frame 1, and at least two gasket feeding trays 2 arranged on the carrier frame 1, a gasket pre-installation mechanism 3, an assembly manipulator 4 and a water pipe fixing device. Mechanism 5, wherein at least two gasket feeding trays 2 are connected to the gasket pre-installation mechanism 3 through the feeding slideway 6, the water pipe fixing mechanism 5 has a gasket pressing device 7 and is fixed with a water pipe 8 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com