Positioning jig for adjusting stage blades and method for processing blade steam channel profiles by using the jig

A blade positioning and blade steam channel technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor machining dimensional accuracy, and the polishing process cannot meet the requirements of drawing accuracy, so as to ensure product quality and processing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

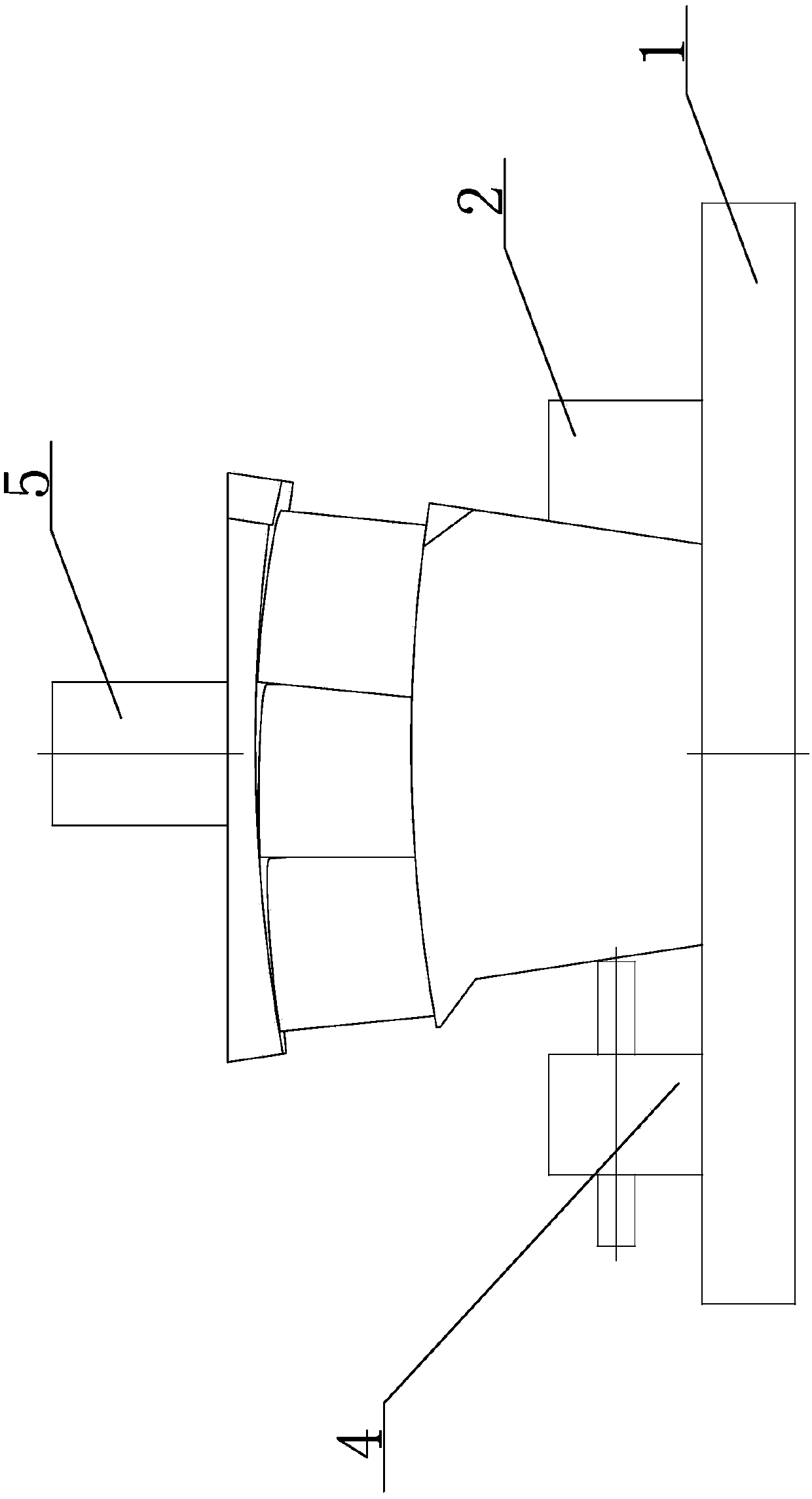

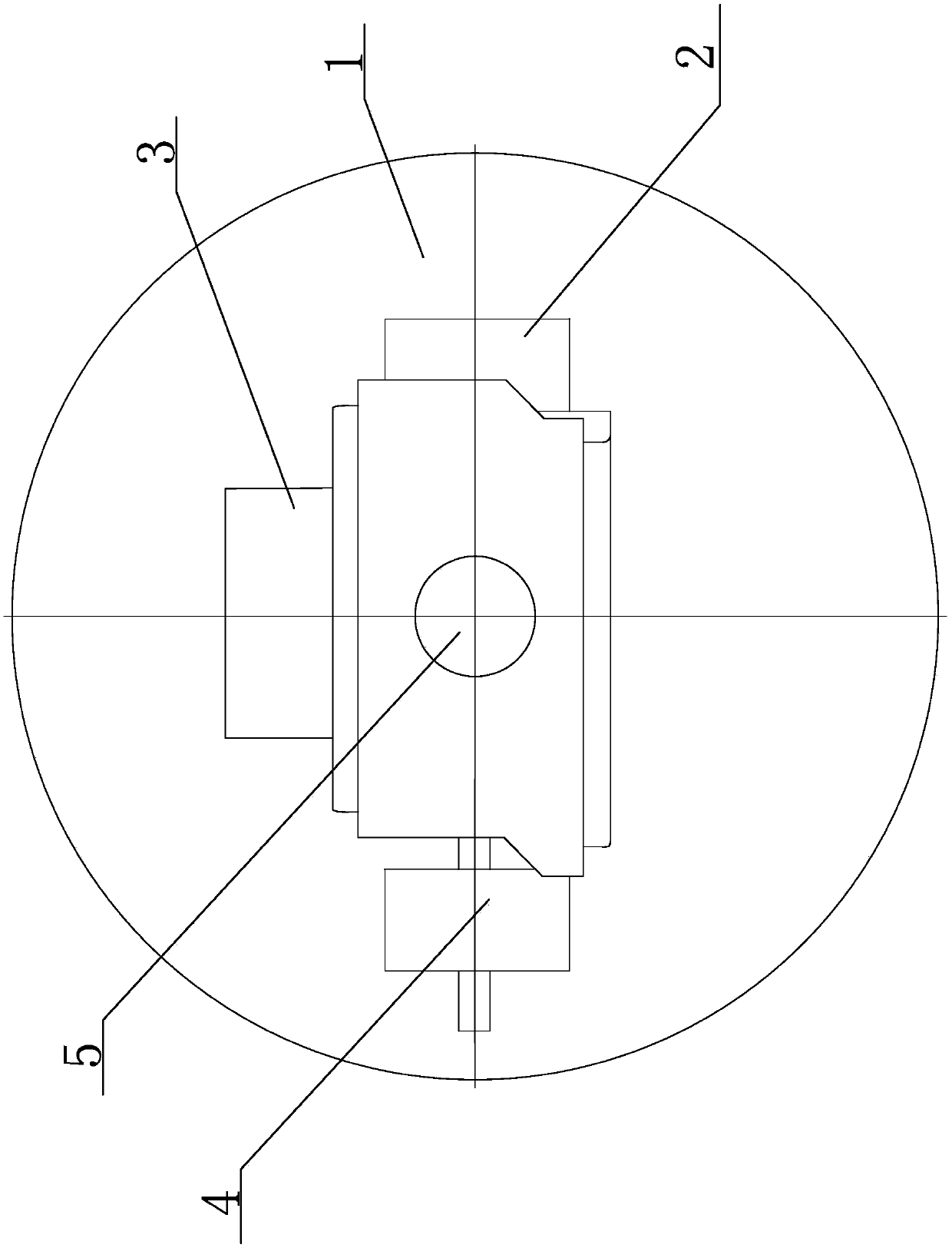

[0022] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, the adjustment stage blade positioning fixture described in this embodiment includes a clamp body 1, a first positioning block 2, a second positioning block 3, a top wire positioning assembly 4 and a top block 5, and the clamp body 1 is plate-shaped body, the clamp body 1 is fixedly installed on the workbench of the machine tool, the first positioning block 2 and the jacking wire positioning assembly 4 are arranged oppositely, and the first positioning block 2 and the jacking wire positioning assembly 4 are relatively fixedly installed on the upper end surface of the clamping body 1 , the second positioning block 3 is installed on the tailstock of the machine tool, one end of the top block 5 is installed on the rotary table of the CNC five-axis milling machine, the other end of the top block 5 is on the root of the blade of the regulating stage, and the blade of the regulating stage bl...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1-Figure 2 Describe this embodiment, the adjustment level blade positioning fixture described in this embodiment, the jackscrew positioning assembly 4 includes a jackscrew block and a jackscrew, the jackscrew block is fixedly installed on the upper end surface of the clamp body 1, and the jackscrew is threadedly installed on the jackscrew On the block, and the top wire top is at the top of the blade on the back diameter side of the regulating stage blade, and the other structures are the same as in the first embodiment.

specific Embodiment approach 3

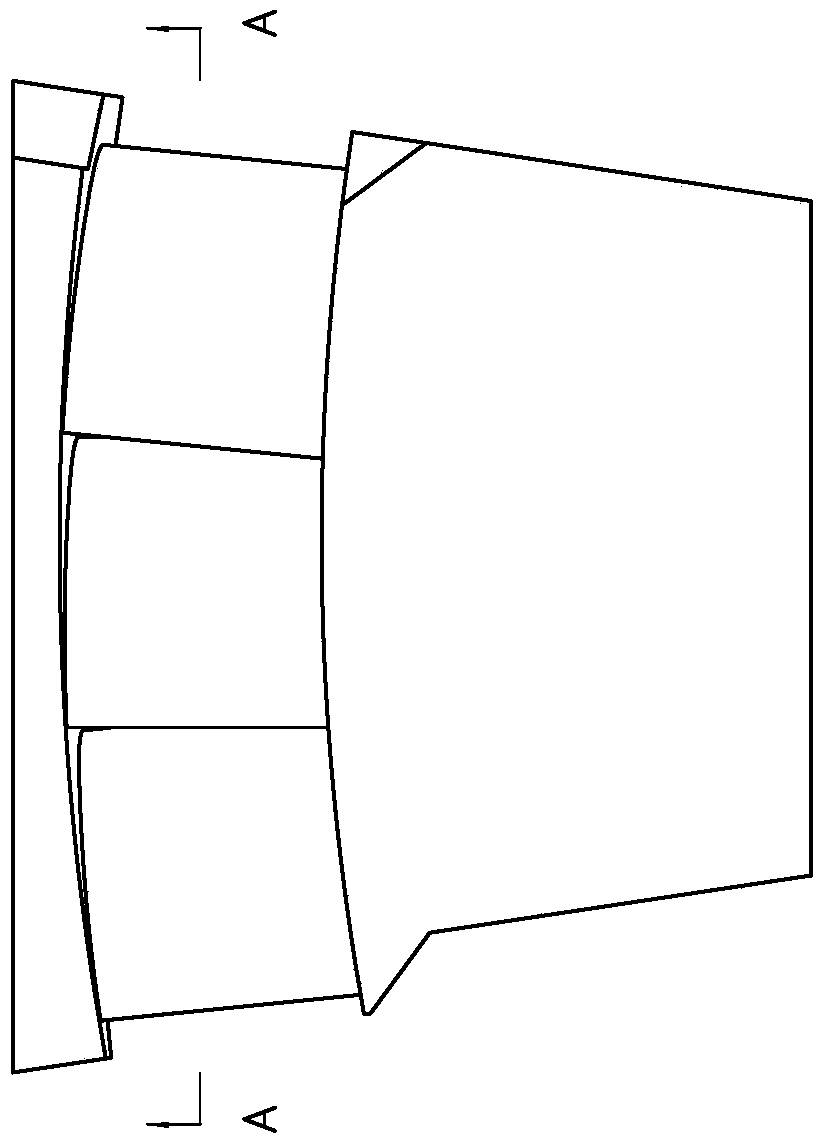

[0024] Specific implementation mode three: combination Figure 1-Figure 7 Describe the present embodiment, the processing method of using the regulating stage blade positioning fixture to process the steam channel profile of the regulating stage blade described in this embodiment, the method is realized according to the following steps:

[0025] Step 1: Installation: Install the clamp body 1 on the workbench of the five-axis CNC milling machine. There are two cavities for the three steam channel profiles of the adjusting stage blade before processing, and the processing surface of each cavity has 0.5mm machining surplus. quantity;

[0026] Step 2: Positioning: Place the blade of the regulating stage upside down on the upper end surface of the clamp body 1, the top wire is on the top of the blade on the back diameter side of the blade of the regulating stage, and the first positioning block 2 is positioned on the inner diameter surface of the blade of the regulating stage. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com