Mechanical arm

A manipulator and articulation technology, applied in the field of manipulators, can solve the problems of difficult manipulator stretching, heavy burden on electric push rods, shortening the service life of electric push rods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further detailed explanation through specific implementation mode below:

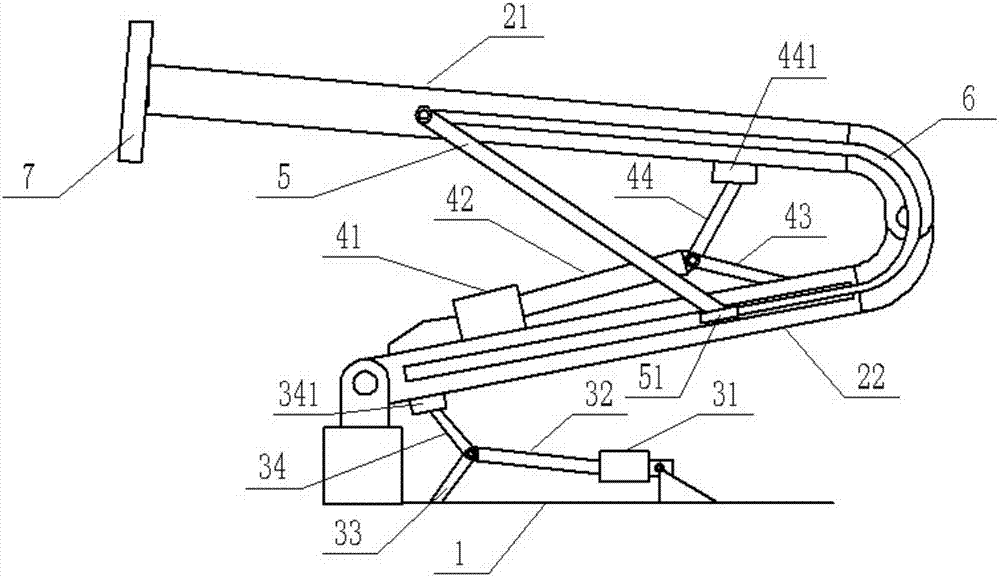

[0014] The reference numerals in the accompanying drawings include: base 1, upper bracket 21, lower bracket 22, first cylinder 31, first telescopic rod 32, first push rod 33, first main push rod 34, first slider 341, the second cylinder 41, the second telescopic rod 42, the second push rod 43, the second main push rod 44, the second slider 441, the support rod 5, the third slider 51, the thick iron wire 6, the plane plate 7 .

[0015] The embodiment is basically as attached figure 1 Shown: a kind of mechanical arm, comprises base 1, the lower bracket 22 that is hinged with base 1, the upper bracket 21 that is hinged with lower bracket 22, is provided with first driving mechanism between base 1 and lower bracket 22, and described first The drive mechanism is installed on the base 1 and includes a first cylinder 31, a first telescopic rod 32 connected to the first cylinder 31, a first main push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com