Sheet torsion rod spring structure, vehicle suspension and manufacturing method of sheet torsion rod spring structure

A manufacturing method and a torsion bar spring technology, which are applied in the manufacture of sheet torsion bar spring structures and in the field of vehicle suspension, can solve the problems of heavy weight, large change angle of the transmission shaft, and large change in the angle of the transmission shaft, so as to achieve production and replacement. Low cost, small change in drive shaft angle, and the effect of improving smooth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

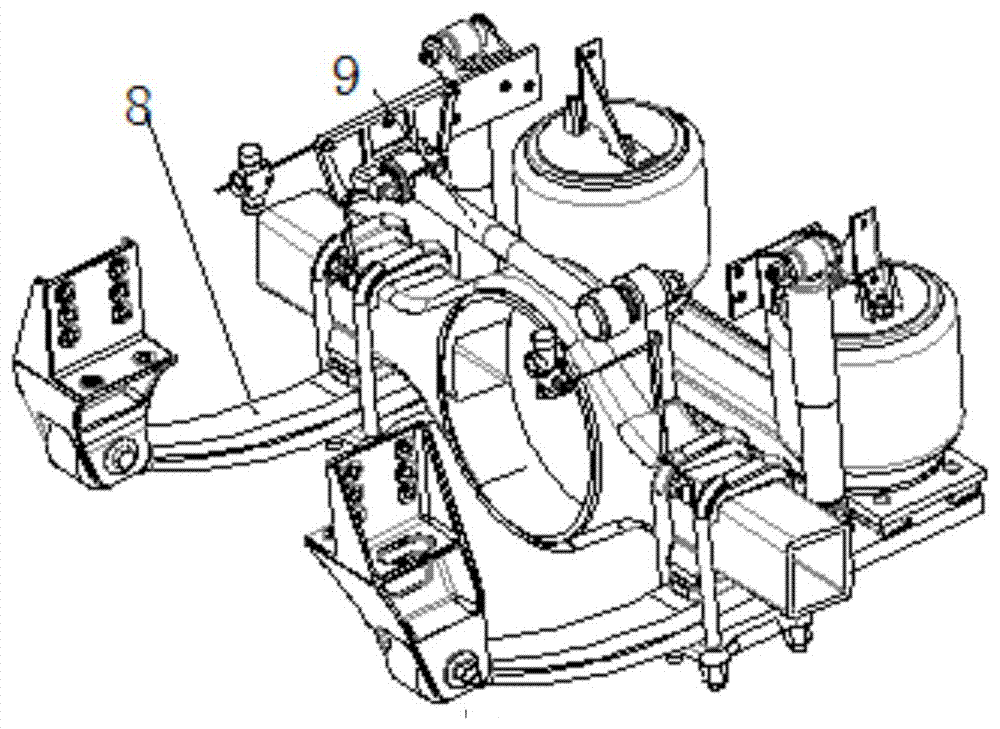

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

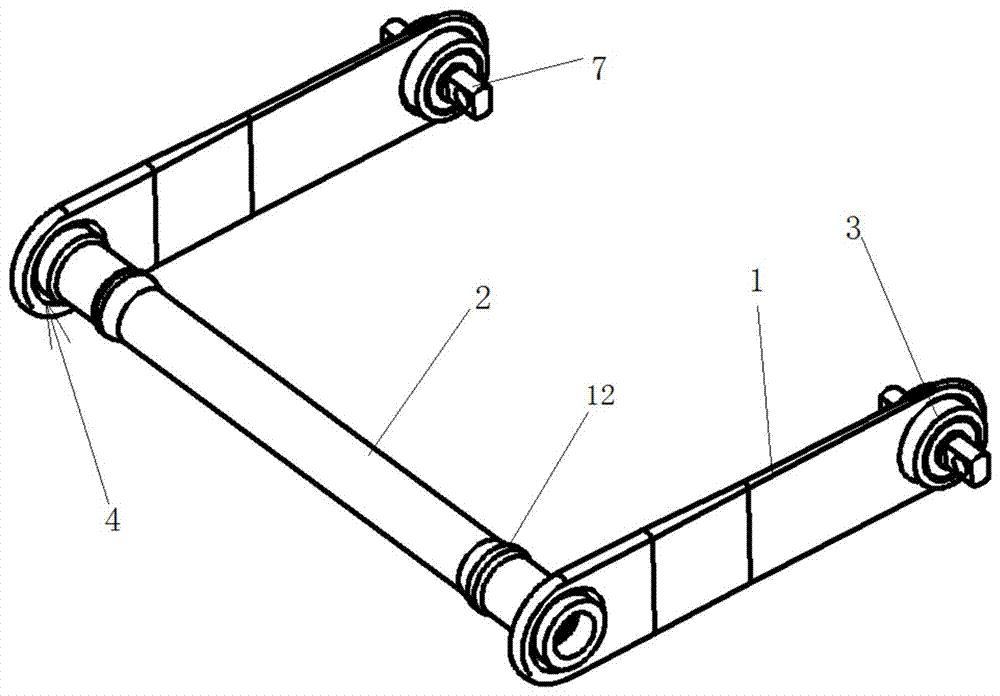

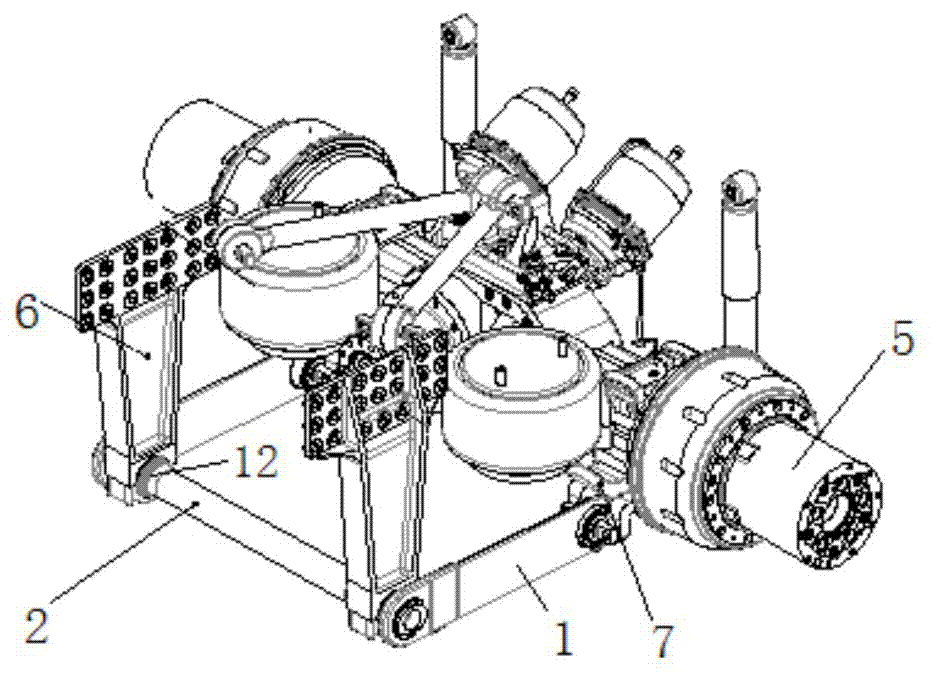

[0028] Such as Figure 1-Figure 2 As shown, the embodiment of the present invention first discloses a leaf torsion bar spring structure, including two leaf springs 1 and a torsion bar 2, one end of any one leaf spring 1 is welded to one end of the torsion bar 2, and the other One end is fixedly connected with a spherical hinge bushing 3, and the two spherical hinge bushings 3 are coaxial and their centerlines are parallel to the centerline of the torsion bar 2 to form a similar parallelogram structure.

[0029] In this embodiment, in order to further reduce weight and realize lightweight design, after finite element simulation analysis, the stress of leaf spring 1 decreases from the connection with torsion bar 2 to the direction of ball joint bushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com