Onboard compact optoelectronic pod

An optoelectronic pod, compact technology, used in aircraft parts, transportation and packaging, etc., can solve the problems of a large number of pod slip rings, low utilization of pod space, large size of pod, etc., to improve reliability. performance and usability, control of structural dimensions, and the effect of reducing the height of the pod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

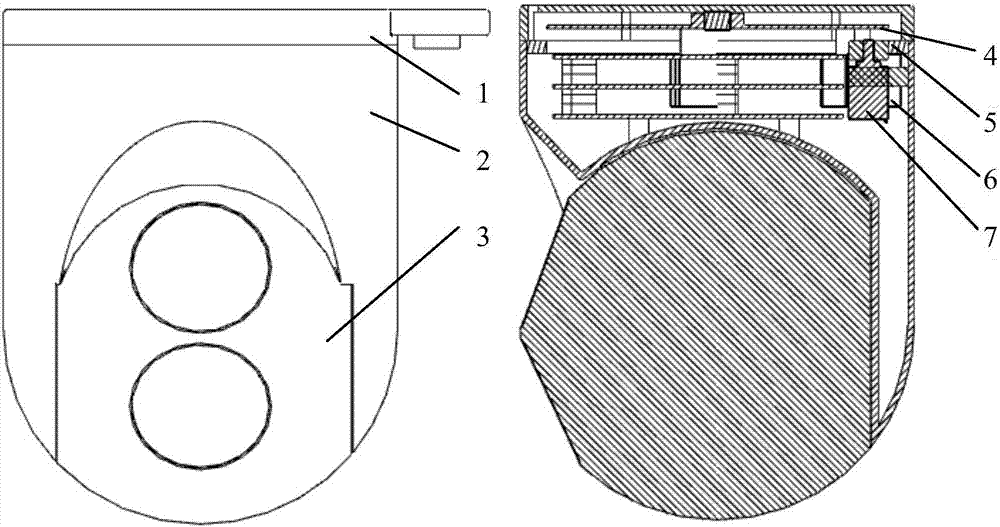

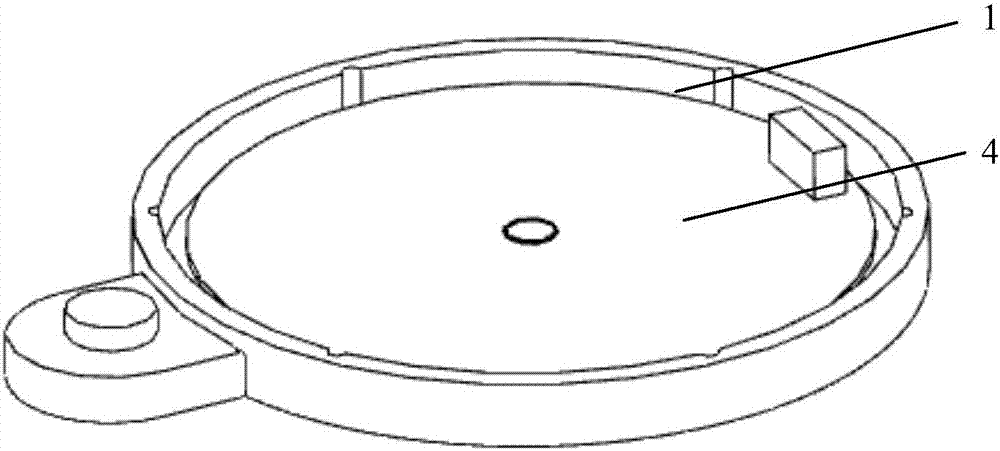

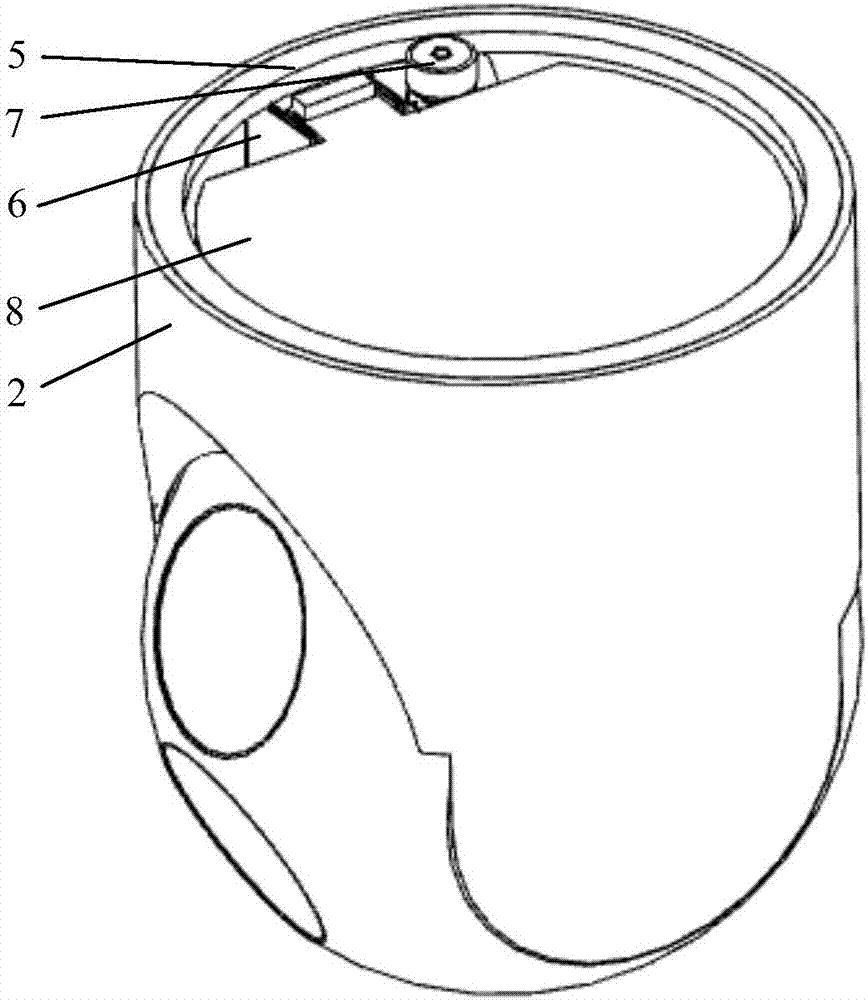

[0015] This embodiment includes an azimuth upper cover 1 , a main frame 2 , an outer pitching component 3 , a disc-type conductive slip ring 4 , a bearing 5 , a clip 6 , a motor 7 and a pod signal processing circuit board 8 .

[0016] Bearing 5 uses a bearing inner ring with a gear, the outer ring of the bearing is fastened to the main frame of the pod, the inner ring of the bearing with the gear is fastened to the azimuth upper cover, and the inner ring of the bearing is driven by a motor. The stator of the special disc-type conductive slip ring is fastened to the azimuth upper cover.

[0017] The conductive slip ring is fixed by the stator of the disc-type conductive slip ring and the azimuth upper cover, and the slip-ring disc rotor uses the clips fixed on the main frame to clamp the slip-ring plug, so that the main frame can rotate with the slip-ring rotor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com