Preceding counting and conveying device for packaging and boxing of oral cigarettes

A conveying device and snus technology, which are applied in the directions of packaging, package protection, transportation and packaging, etc., can solve the problems of inconvenient cleaning of snus pouches, easy inclusion of tobacco powder, and increased airflow, etc., and achieve accurate counting. And the effect of dust removal, weighing, buffering and conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

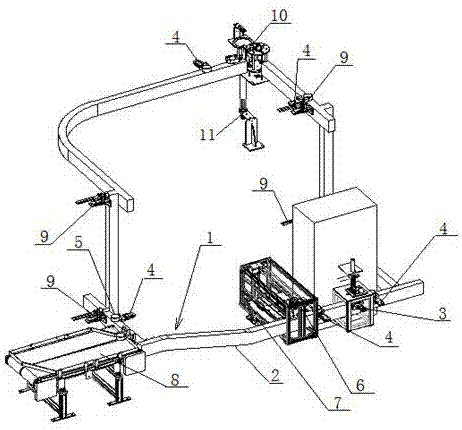

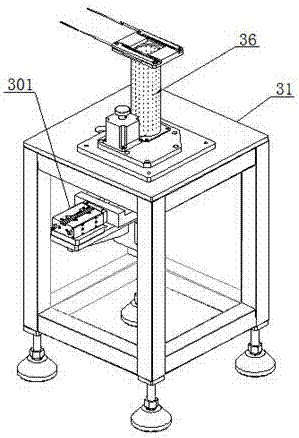

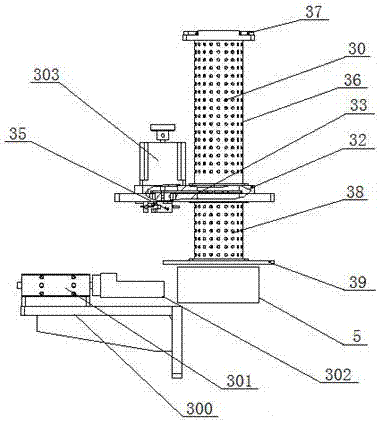

[0046] Such as Figure 1-11 Shown as follows: a pre-counting and conveying device for packaging cigarettes into a box, comprising a cigarette-containing pouch packaging machine and a circulating conveying line 1 matched with it. The circulating conveying line 1 includes a group set at each station On the conveyor 2, and the counting mechanism 3, the feeding device 4, the transfer box 5, the final weighing mechanism 6, the reject assembly 7, the buffer mechanism 8, the lifting and pushing assembly 9, the upper The feeding mechanism 10, the feeding assembly 11, the counting mechanism 3 is arranged on one side of the cigarette-containing pouch packaging machine and one end of the circulating conveying line 1 as a starting station for conveying. The end weighing mechanism 6 , Rejecting component 7, lifting and pushing component 9, feeding mechanism 10, and feeding component 11 are arranged on the circulating conveyor line 1 in sequence, arranged in continuous stations, and a distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com