Lifting tool and method special for lifting brick fuel and crane for lifting tool and method

A spreader and carbon brick technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of uneven stacking of carbon bricks, not on the same line, and failure to solve the stacking of carbon bricks, etc., to ensure the contact area and increase Effect of high gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

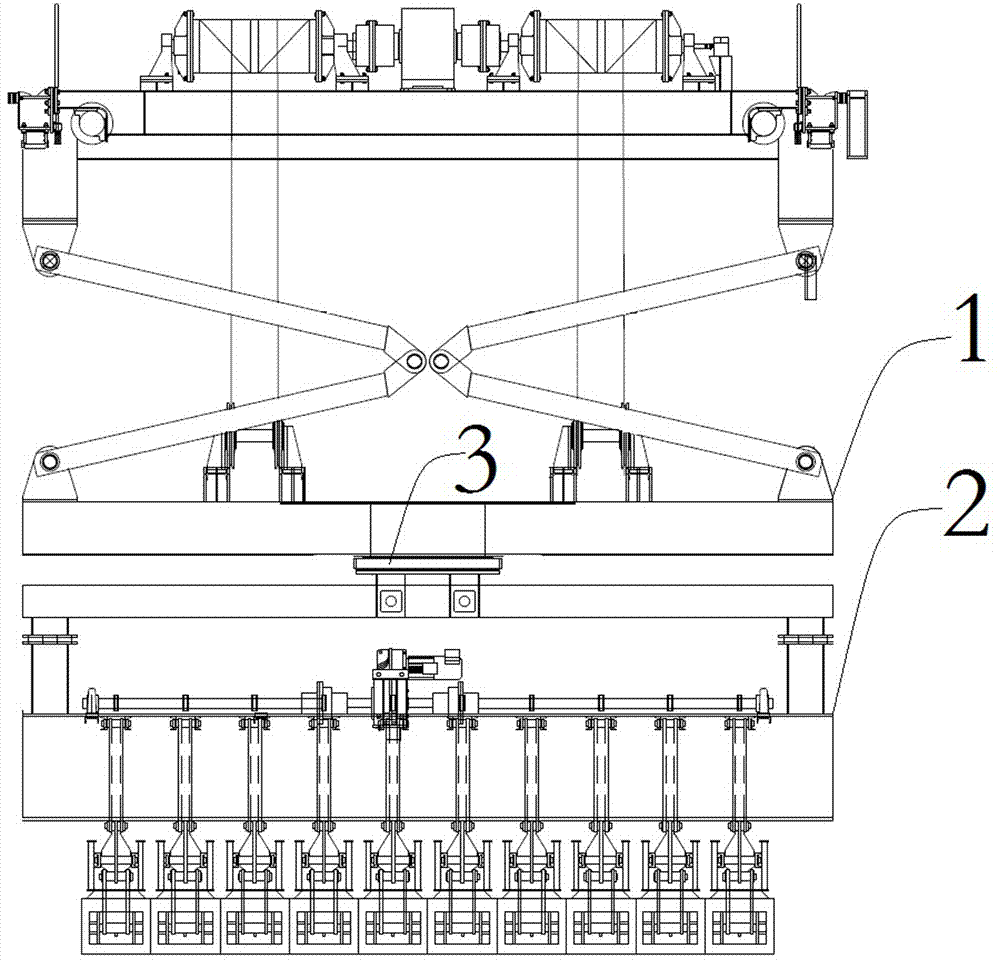

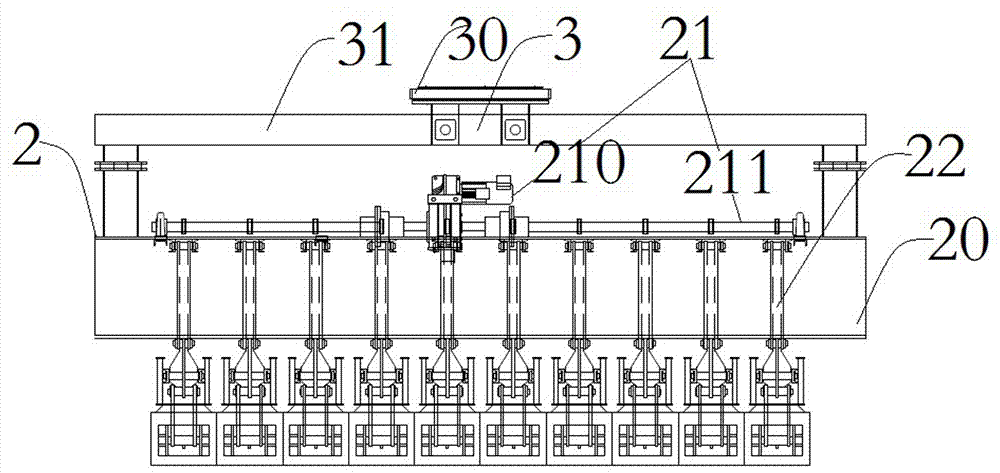

[0038] Such as Figure 1~4 As shown, in this embodiment, a hoisting device dedicated to hoisting carbon bricks is provided, including a hoisting device 1 and a hoisting device 2 , and the hoisting device 1 and the hoisting device 2 are connected through a slewing mechanism 3 .

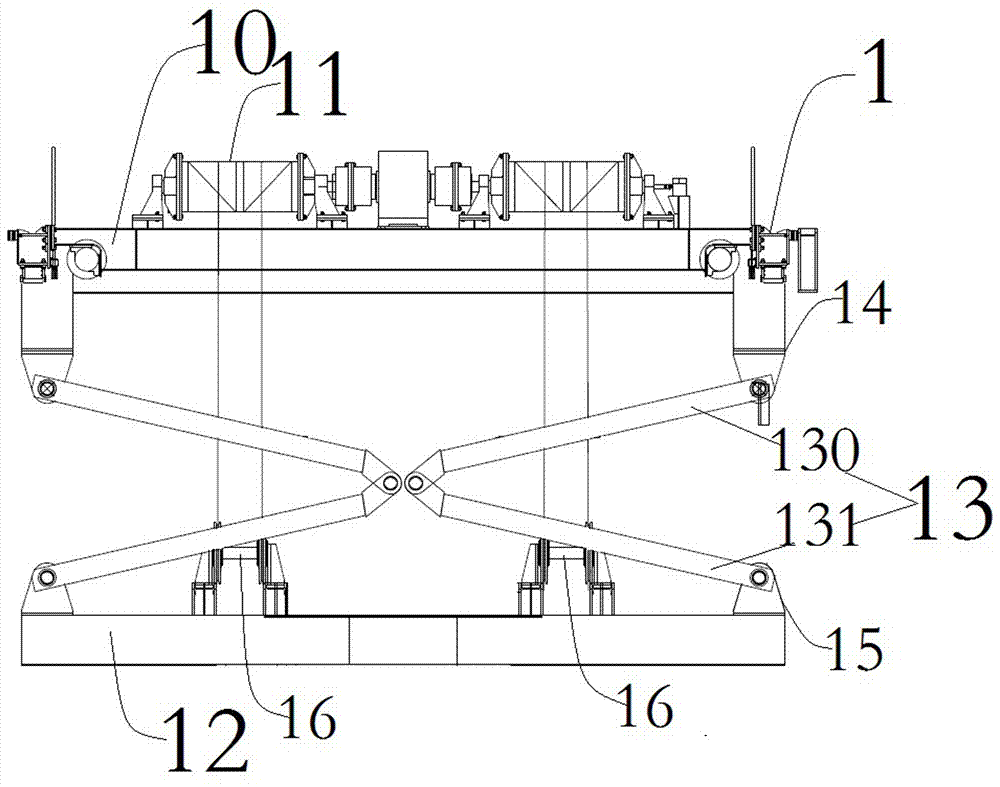

[0039] Such as figure 2 As shown, the hoisting device 1 includes a spreader main beam 10, two winches 11 arranged on the spreader main beam, and a sub-beam 12 connected by steel ropes or belts on the winches 11;

[0040] The secondary beam 12 is provided with two pulley mechanisms 16 that cooperate with the hoist 11, and the pulley mechanisms 16 are correspondingly arranged in the vertical direction of the hoist 11, and are connected with the hoist 11 by steel ropes or belts;

[0041] A connecting rod device 13 is also included between the main beam 10 of the spreader and the sub-beam 12. The connecting rod device 13 includes a connecting rod 130 and a connecting rod 131. One end of the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com