Anti-loosening and anti-skidding combined gasket

A gasket and anti-skid technology, which is applied in the field of mechanical parts, can solve the problems of easy loose gaskets and achieve good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

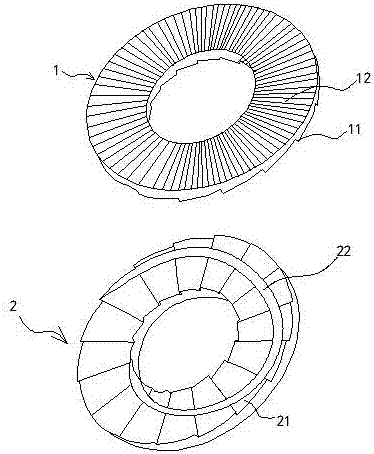

[0021] Example: A combination of anti-loose and anti-skid gaskets

[0022] See attached figure 1 , including an upper gasket 1 and a lower gasket 2 for matching use, the upper gasket 1 is an upper ring gasket structure, and a number of positively rotating upper locking grooves are provided on the front of the upper ring gasket structure 12. The plurality of upper locking grooves 12 are evenly arranged in sequence along the circumference of the upper annular gasket structure, and a plurality of counter-rotating upper locking teeth 11 are provided on the reverse side of the upper annular gasket structure.

[0023] The lower gasket 2 is a lower annular gasket structure, on the front of the lower annular gasket structure, there are several counter-rotating lower locking grooves, and the locking grooves are evenly arranged in sequence along the circumference of the lower annular gasket , on the opposite side of the lower ring gasket structure are provided with a number of forward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com