High-temperature calibration device for probe microphone

A calibration device and microphone technology, which is applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem of reducing the accuracy and reliability of calibration results, unable to install symmetrically, and lacking related research on high-temperature environment acoustic calibration, etc. problems, to achieve the effect of broadening the calibration temperature range, improving accuracy and credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

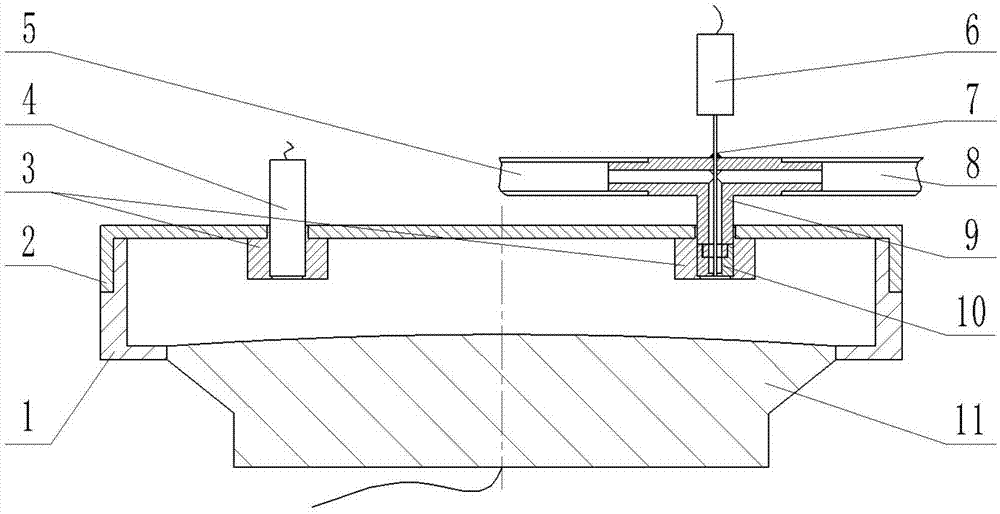

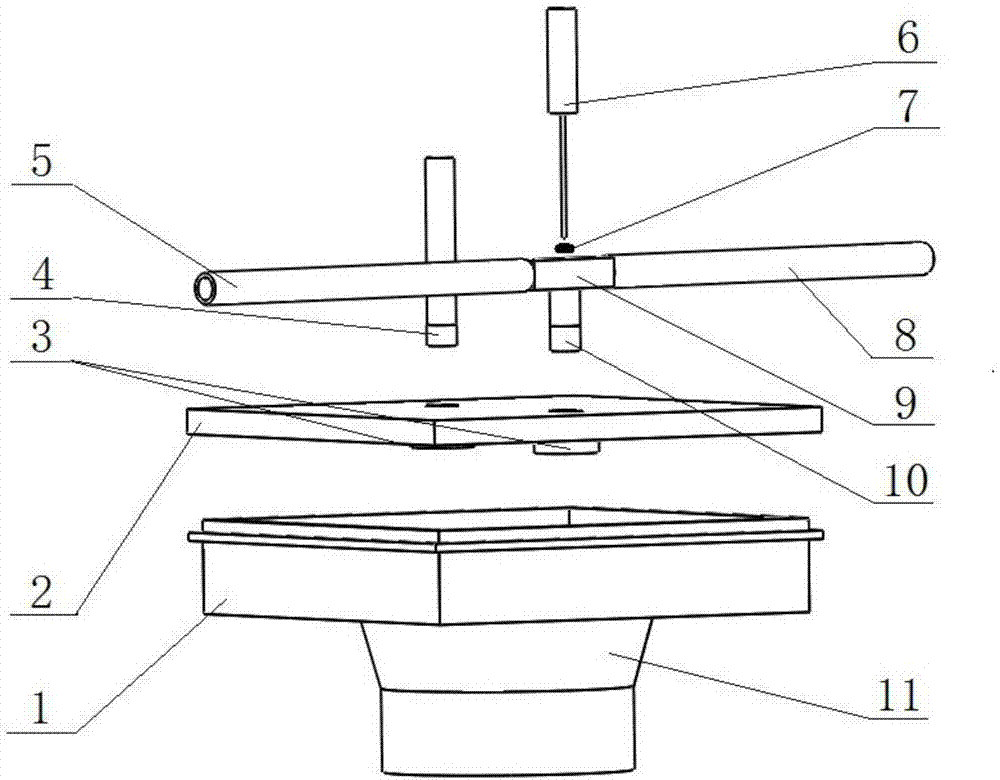

[0033] The overall structure is as figure 1 shown, supplemented by 3D assembly splits such as figure 2 to supplement. The calibration object is the probe microphone 6 of any type, and the reference object is the standard microphone 4 . The device body consists of two parts: first, the coupling cavity for high temperature calibration (lower coupling cavity 1, upper coupling cavity 2, isolation lining 3, sound source 11), which is the sound field environment for probe microphone calibration; The plug main body 9, the heat plug lower cover 10, the air inlet pipe 5, and the air outlet pipe 8) are the thermal field environment and the adapter for the calibration of the probe microphone.

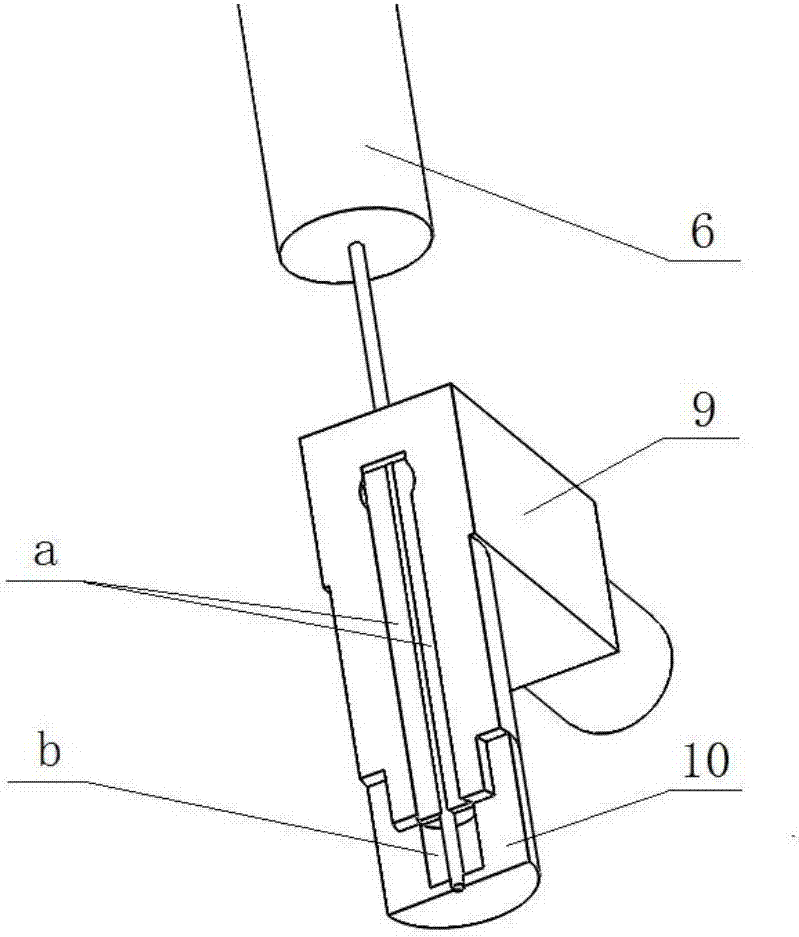

[0034] In order to facilitate machining, the main body 9 of the glow plug is divided into two parts: the upper part of the glow plug and the lower part of the glow plug 10; To open a ventilation groove, it is necessary to ensure that the two ventilation grooves and the central through hole kee...

Embodiment 2

[0042] In addition, according to different requirements, the present invention can also be designed as an opposite design, such as Figure 4 shown, the principle and method of use are the same as figure 1 The designed side-by-side structure is exactly the same, except that the standard microphone 4 and the probe microphone 6 are changed from side-by-side installation to opposite installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com