A production quality inspection system for electric locomotive connectors

A detection system and technology for electric locomotives, which are applied in the testing of machine/structural components, measurement of electrical variables, and testing of mechanical components, etc., can solve problems such as difficulty in detection of needle shrinkage, failure of control systems, and inability to guarantee production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer and more comprehensive understanding of the present invention, its specific implementation is now described with reference to the accompanying drawings.

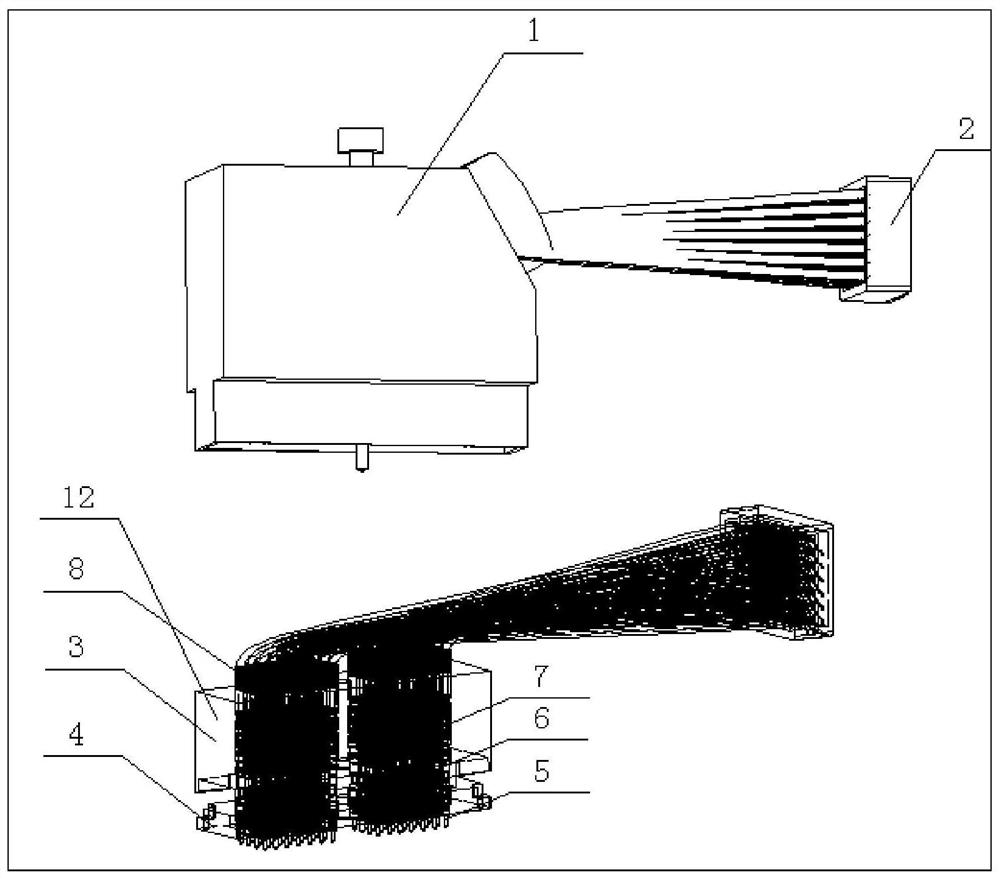

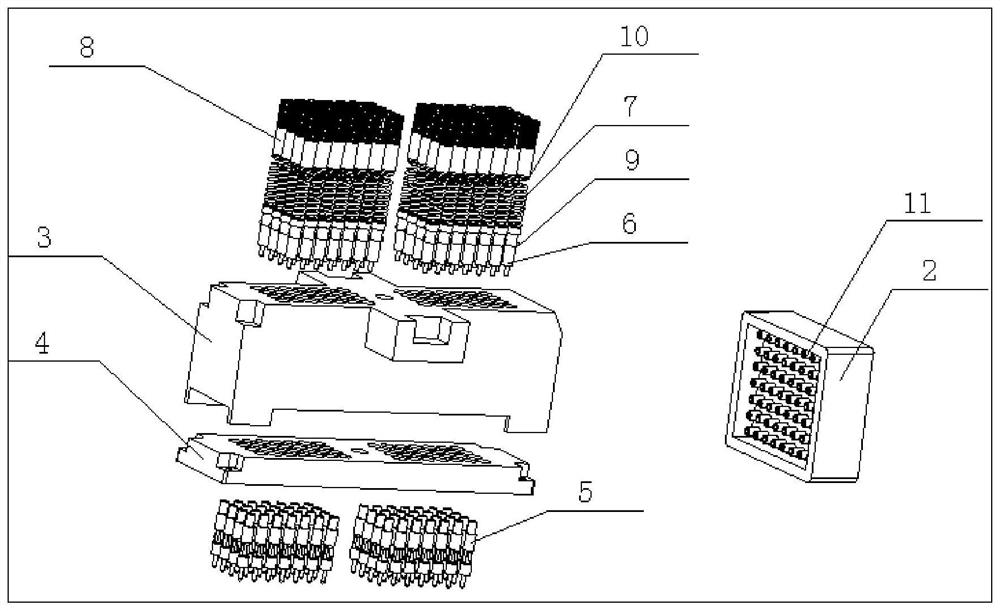

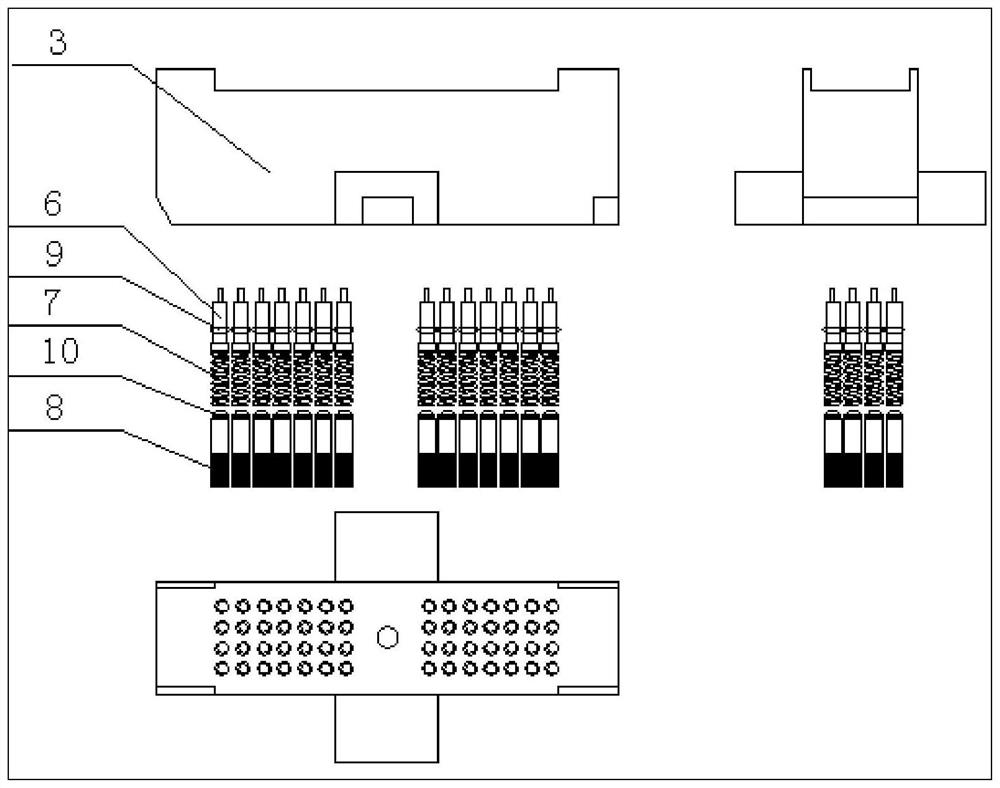

[0035] The present invention provides a production quality inspection system for electric locomotive connectors. The system includes a housing 1, an oil pressure detection system 12, and an electrical detection system, such as figure 1 . The shell 1 is provided with a boss c, and the boss c is provided with a mounting hole, which is used to set the pin plate 4 to prevent the pin plate from moving along the z direction; the shell 1 is provided with a boss b, which is used to set the oiling plate 3 , used to clamp the oil injection plate 3 to prevent the oil injection plate 3 from moving along the z direction, such as figure 2 , Figure 8 shown.

[0036] In this embodiment, the oil pressure detection system 12 includes a docking pin 5 , a pin plate 4 , an oil filling plate 3 , a piston 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com