Chip antenna and electronic equipment using the chip antenna

A chip antenna, patch antenna technology, applied in the direction of antenna, antenna array, antenna components, etc., can solve the problem that the signal cannot be radiated to a wider angle range, and achieve the effect of widening the signal radiation angle and improving the omnidirectionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

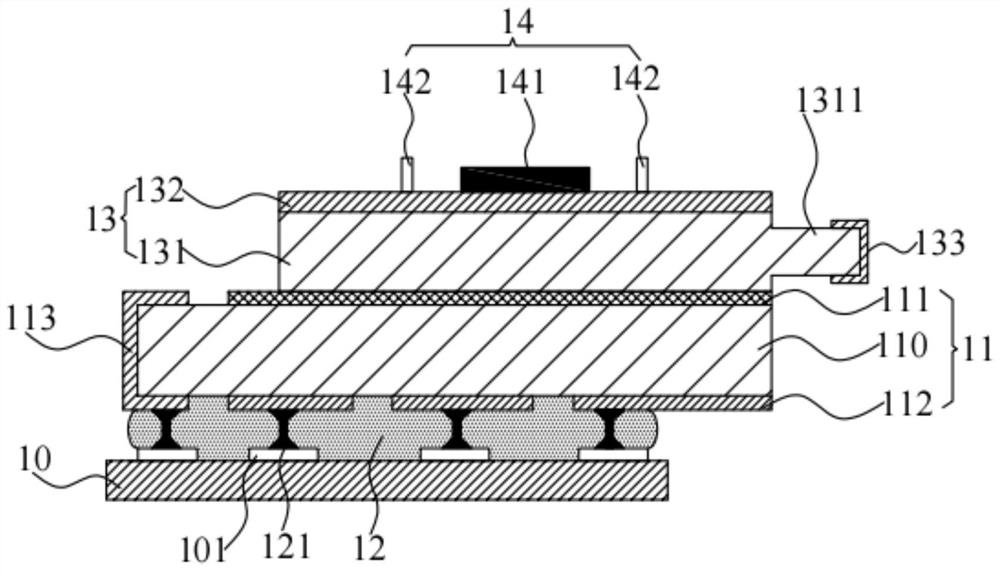

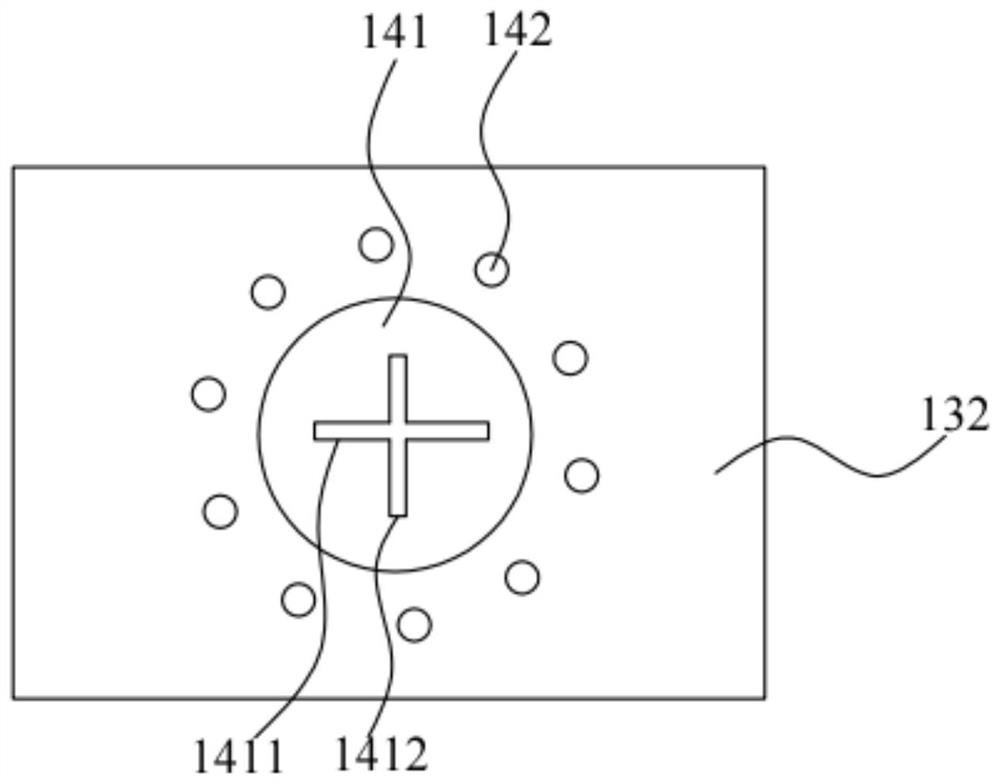

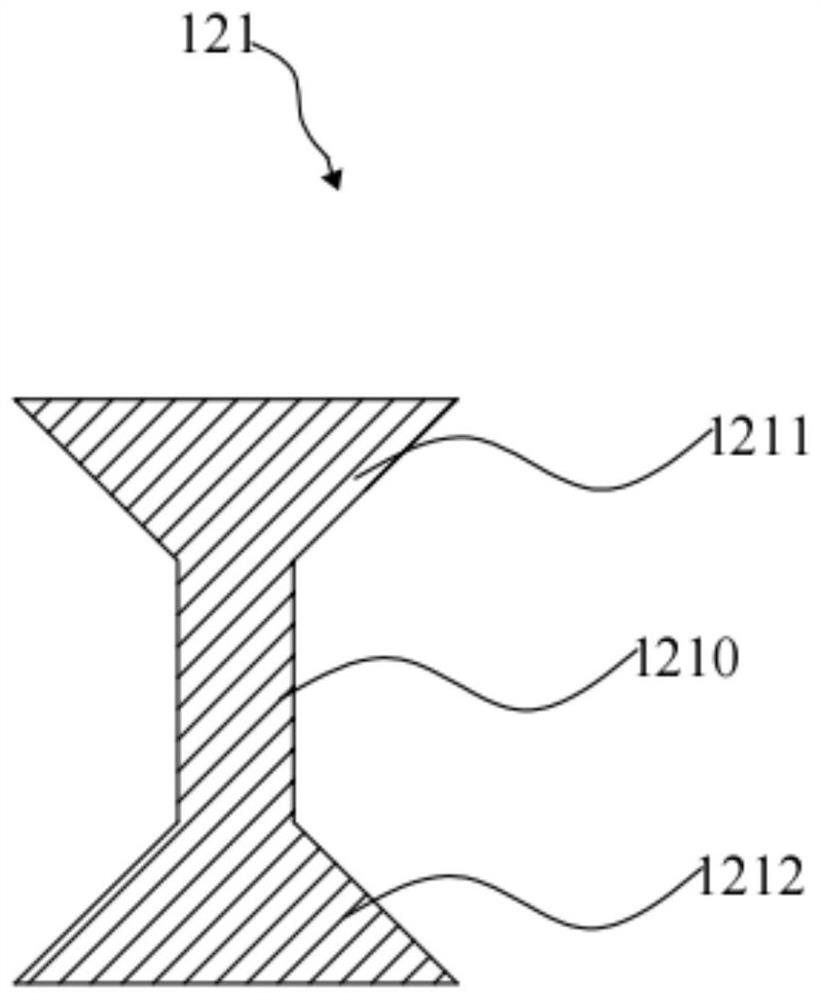

[0037]SeeFigure 1 to Figure 3 , A chip antenna includes a base chip 10, wherein a first patch antenna 11 and a second patch antenna 13 are provided above the base chip 10, and the upper surface of the first patch antenna 11 is The lower surfaces of the second patch antenna 13 are attached to each other.

[0038]Wherein, the first patch antenna 11 includes a metal microstrip feed line 111, a first dielectric layer 110, and a first conductive layer 112 arranged in order from top to bottom. The second patch antenna 13 includes a metal radiation patch 132 and a second dielectric layer 131 arranged in order from top to bottom. In addition, an underfill layer 12 is also provided between the base chip 10 and the first patch antenna 11, and the base chip 10 and the first patch antenna 11 are electrically connected. A signal emitting component 14 is provided on the upper surface of the metal radiation patch 132. The signal emitting component 14 includes a signal radiating part 141 for emitting ...

Embodiment 2

[0045]SeeFigure 4 to Figure 6 , A chip antenna includes a base chip 10, wherein a first patch antenna 11 and a second patch antenna 13 are provided above the base chip 10, and the upper surface of the first patch antenna 11 is The lower surfaces of the second patch antenna 13 are attached to each other.

[0046]Wherein, the first patch antenna 11 includes a metal microstrip feed line 111, a first dielectric layer 110, and a first conductive layer 112 arranged in order from top to bottom. The second patch antenna 13 includes a metal radiation patch 132 and a second dielectric layer 131 arranged in order from top to bottom. In addition, an underfill layer 12 is also provided between the base chip 10 and the first patch antenna 11, and the base chip 10 and the first patch antenna 11 are electrically connected. A signal emitting component 14 is provided on the upper surface of the metal radiation patch 132, and the signal emitting component 14 includes a signal radiating part 141a for emit...

Embodiment 3

[0054]SeeFigure 7 to Figure 9 , A chip antenna includes a base chip 10, wherein a first patch antenna 11 and a second patch antenna 13 are provided above the base chip 10, and the upper surface of the first patch antenna 11 is The lower surfaces of the second patch antenna 13 are attached to each other.

[0055]Wherein, the first patch antenna 11 includes a metal microstrip feed line 111, a first dielectric layer 110, and a first conductive layer 112 arranged in order from top to bottom. The second patch antenna 13 includes a metal radiation patch 132 and a second dielectric layer 131 arranged in order from top to bottom. In addition, an underfill layer 12 is also provided between the base chip 10 and the first patch antenna 11, and the base chip 10 and the first patch antenna 11 are electrically connected. A signal emitting component 14 is provided on the upper surface of the metal radiation patch 132, and the signal emitting component 14 includes a signal radiating part 141a for emit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com