A new type of object processing extrusion molding device

An extrusion molding and object technology, which is applied in the field of new object processing extrusion molding devices, can solve problems such as inconvenience in use, reduced work efficiency, and troublesome operation, and achieves the effects of convenient use, improved work efficiency, and easy placement and taking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

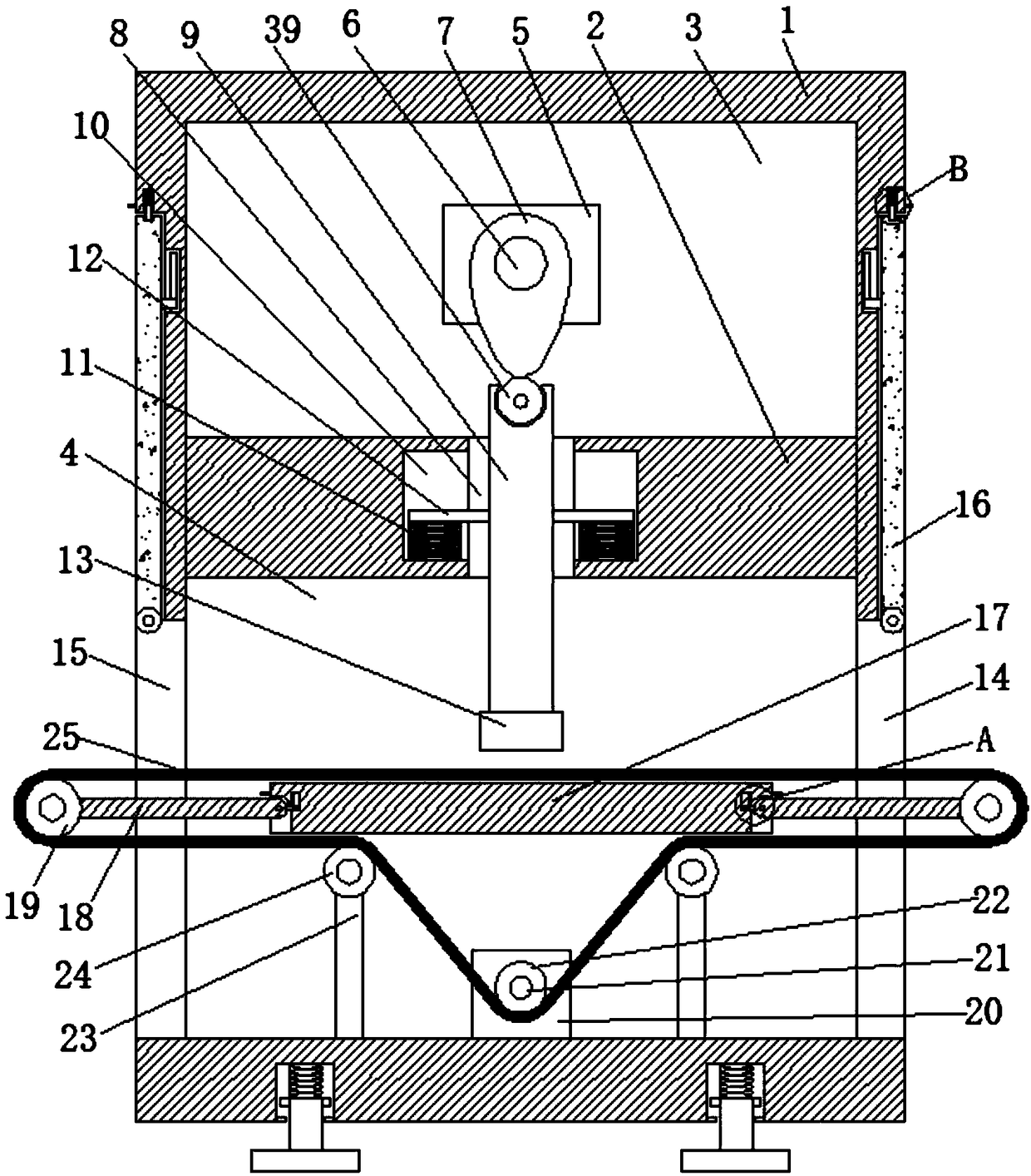

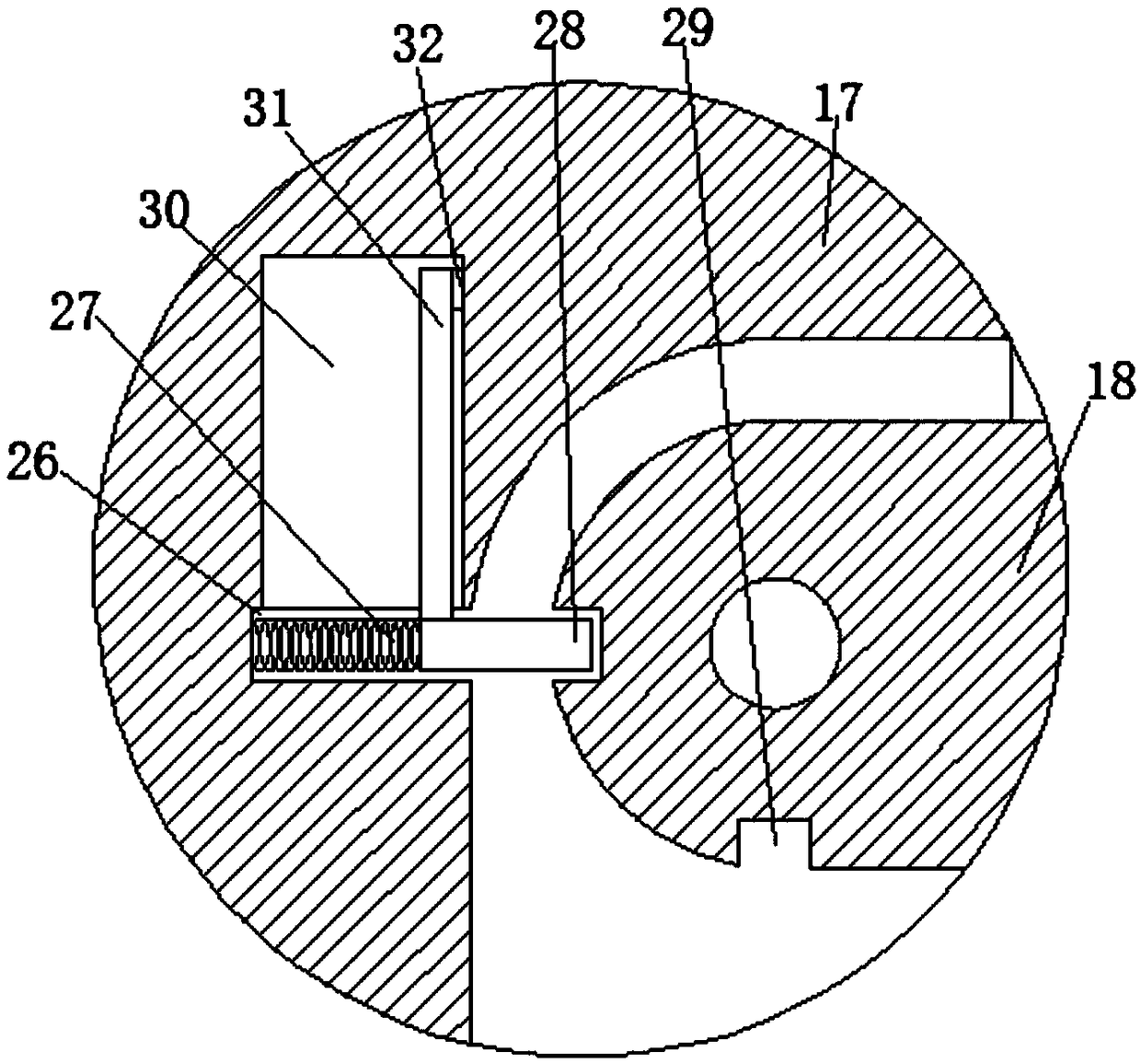

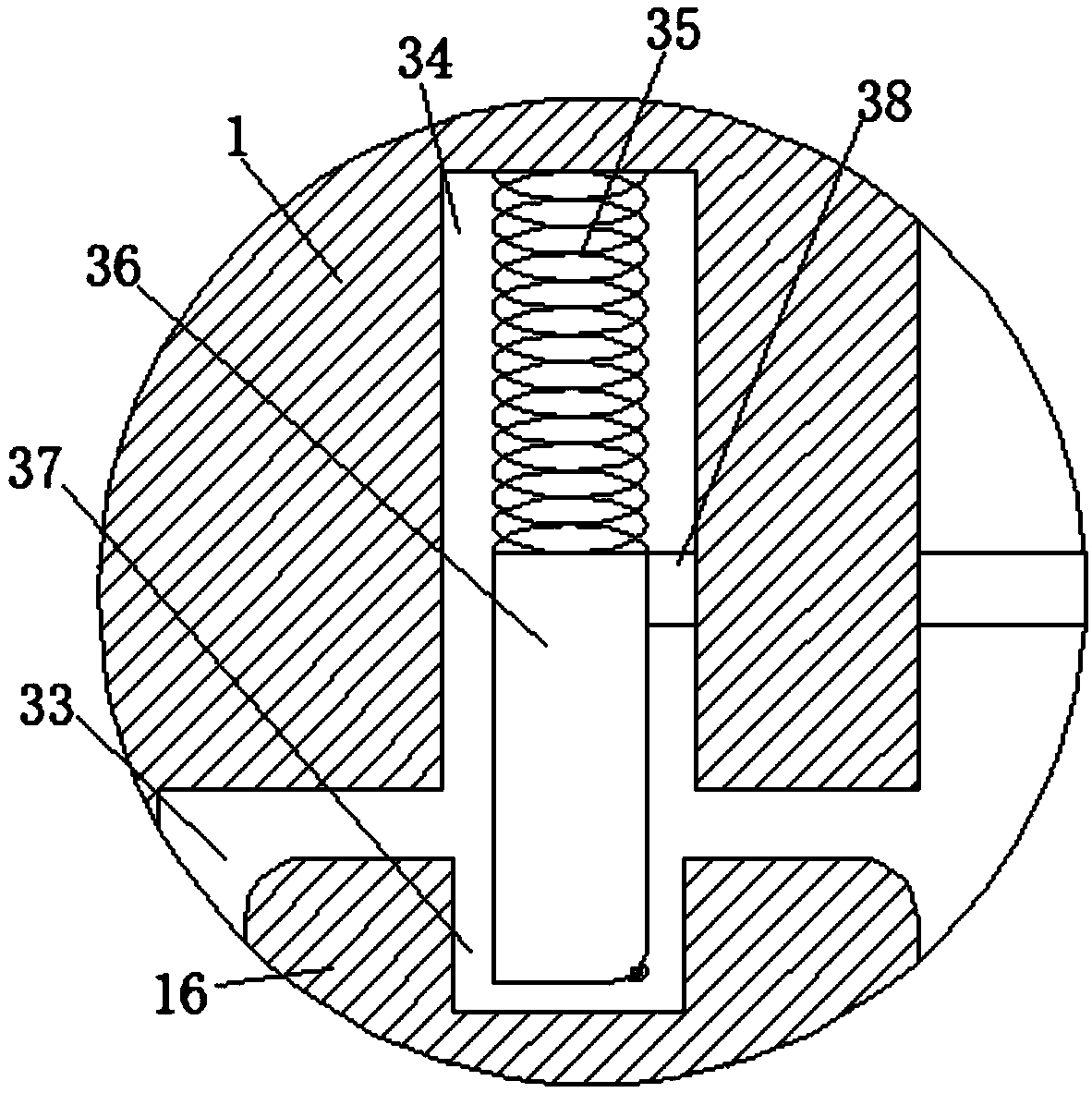

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0017] refer to Figure 1-3 , a new type of object processing extrusion molding device, including a housing 1, the housing 1 is hollow, the housing 1 is provided with a third groove with an opening downward, and the upper inner wall of the third groove passes through the fourth The spring is connected to the base, and the device will vibrate during operation or other conditions. The vibration is greatly weakened by the elastic force of the fourth spring and then transmitted to the ground, which effectively reduces the noise pollution caused by the vibration of the device hitting the ground. The third concave Both inner walls of the groove are provided with limit bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com