A metal pipe welding heat exchange device

A technology for heat exchange devices and metal pipes, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of affecting the metal structure of the weld, poor cooling effect, uneven preheating, etc., and achieve good wetting effect, Improved welding efficiency and improved flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take pipes with a nominal diameter of DN100 to DN150 as an example:

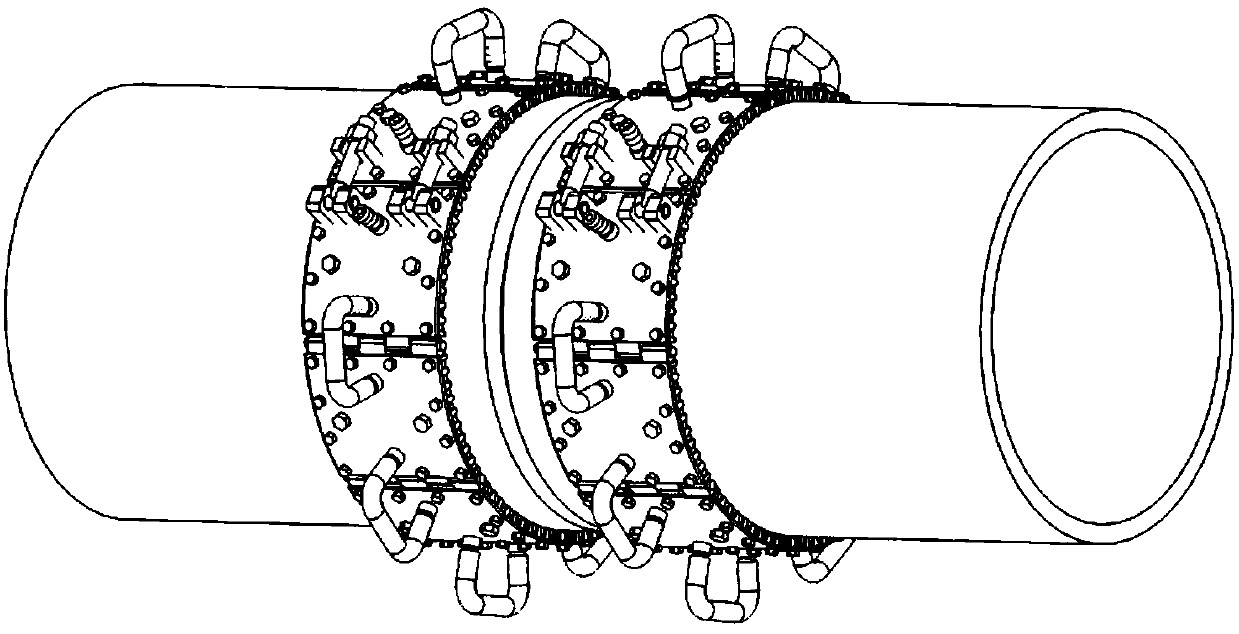

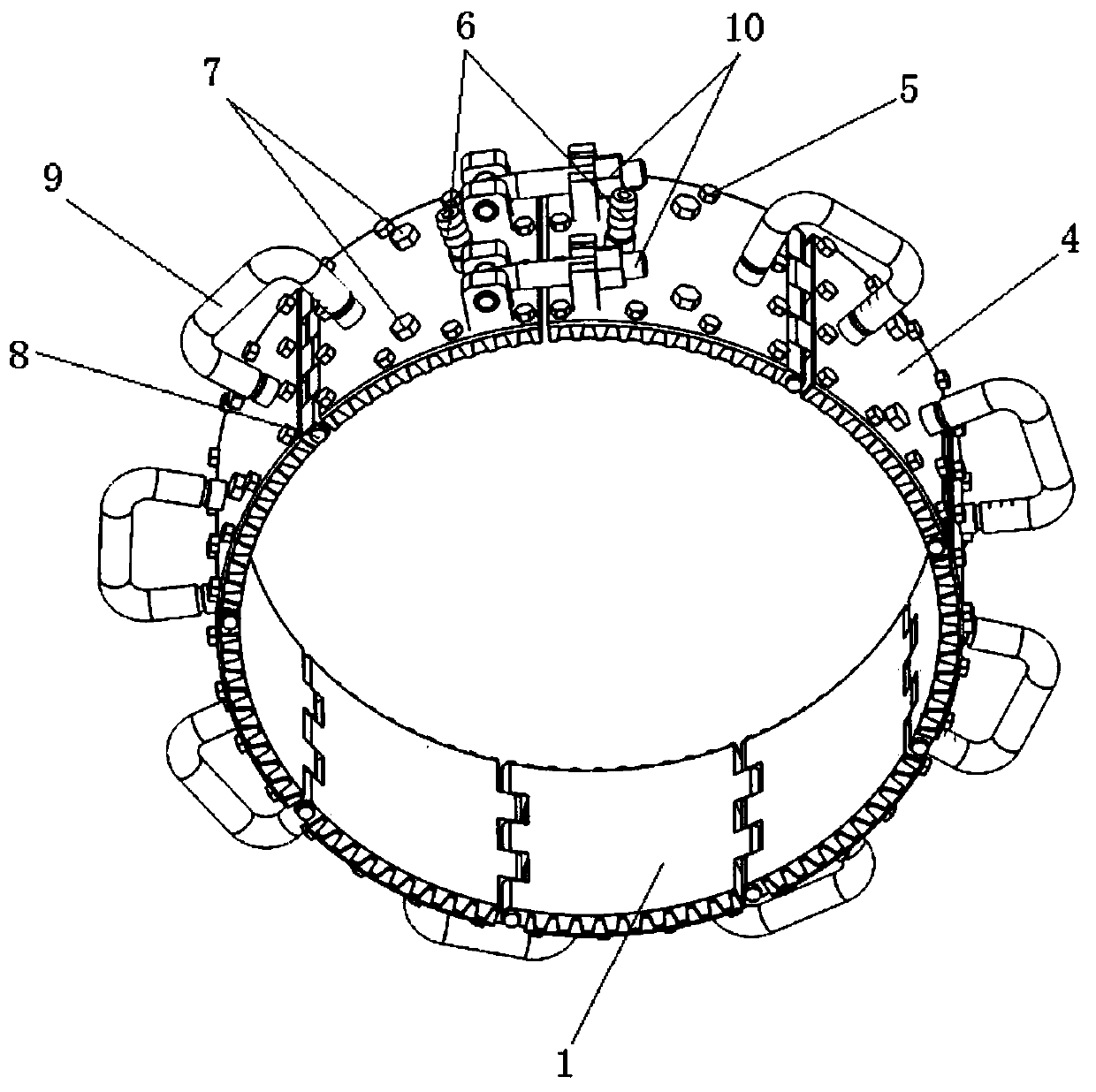

[0034] as attached Figure 1-5 As shown, a metal pipe welding heat exchange device of this patent includes multi-section arc-shaped plate heat exchange fins, inter-node connecting pins 8 , inter-node connecting pipes 9 and adjusting bolts 10 .

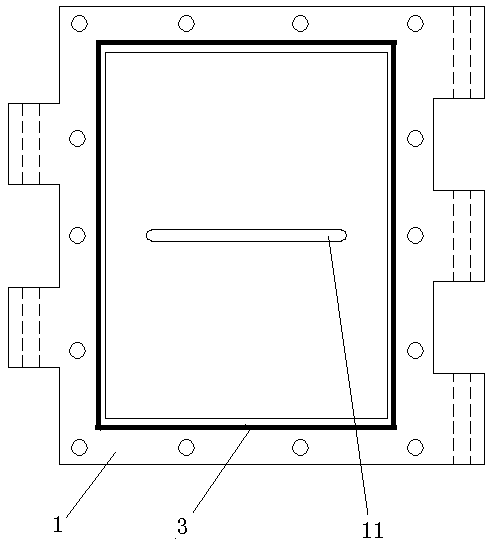

[0035] The arc-shaped plate heat exchanger includes arc-shaped copper plate 1, foam copper 2, sealing ring 3, arc-shaped stainless steel shell 4 and compression bolt 5; The outer side of the arc-shaped red copper plate 1; the width of the arc-shaped red copper plate 1 is 80 mm, the arc diameter is ø140, and the arc length is 86 mm.

[0036] A water tank is provided in the central area of the outer arc surface of the arc-shaped red copper plate 1, and a 2 mm reinforcing rib 11 is provided inside the water tank along the arc direction; a sealing groove is provided on the frame of the water tank, and a sealing ring 3 is arranged in the sealing groove; foam cop...

Embodiment 2

[0041] Embodiment 2 has the same technical solution as Embodiment 1, but adopts an arc-shaped red copper plate 1 with an arc diameter of ø325 and an arc length of 85 mm, which is suitable for pipes with a nominal diameter of DN200-DN350.

Embodiment 3

[0043] The technical solution of embodiment 3 is also the same as that of embodiment 1. The arc-shaped red copper plate 1 with an arc diameter of ø508 and an arc length of 159 mm is used to adapt to pipes with a nominal diameter above DN400.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com