Handheld electric tool noise and vibration reducing device

A technology of hand-held electric tools and vibration damping devices, which is applied in the direction of portable motorized devices and manufacturing tools, which can solve the problems of motor part damage and loud noise, and achieve the effect of reducing noise and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

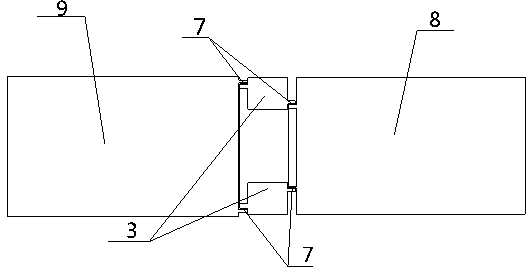

[0028] see Figure 1-2 A noise reduction and vibration reduction device for a hand-held electric tool, comprising a clamping transmission part of the hand-held electric tool and a motor output part, the motor output part is connected to the clamping transmission part of the hand-held electric tool through the noise reduction and vibration reduction device; The noise reduction and vibration reduction device includes an annular metal extension section fixedly connected to the end faces of the output part of the motor and the clamping transmission part of the hand-held electric tool, a pair of annular metal plates, and a noise reduction and shock absorption part filled between the pair of annular metal plates. The material and the ring-shaped metal extension section fixedly connected to the left and right sides of a pair of ring-shaped metal plates, the ring-shaped metal extension section located on the end face of the motor output part and the clamping transmission part of the ha...

Embodiment 2

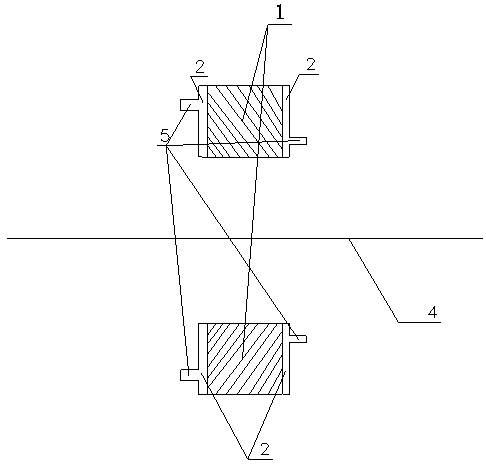

[0031] see Figure 2-4 A noise reduction and vibration reduction device for a hand-held electric tool, comprising a clamping transmission part of the hand-held electric tool and a motor output part, the motor output part is connected to the clamping transmission part of the hand-held electric tool through the noise reduction and vibration reduction device; The noise reduction and vibration reduction device includes an annular metal extension fixedly connected to the end surface of the motor output part and the clamping transmission part of the hand-held electric tool, a pair of annular metal plates, and a ring-shaped ring is integrally formed in the middle of the annular metal plate facing the motor output part. Flange, noise-reducing and shock-absorbing material filled between a pair of ring-shaped metal plates, a ring-shaped metal extension fixedly connected to the side of the ring-shaped metal plate facing the clamping transmission part of the hand-held electric tool, locate...

Embodiment 3

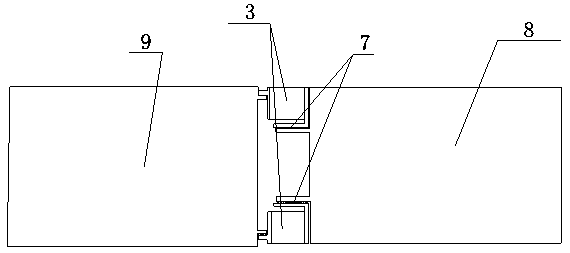

[0034] see Figure 5-6 A noise reduction and vibration reduction device for a hand-held electric tool, comprising a clamping transmission part of the hand-held electric tool and a motor output part, the motor output part is connected to the clamping transmission part of the hand-held electric tool through the noise reduction and vibration reduction device; The noise reduction and vibration reduction device includes an annular metal extension section fixedly connected to the end face of the output part of the motor and the clamping transmission part of the hand-held electric tool, a pair of annular metal plates arranged on a coaxial line, and a pair of annular metal plates filled between the pair of annular metal plates. Noise-reducing and shock-absorbing materials, the ring-shaped metal extension sections on the end faces of the motor output part and the clamping transmission part of the hand-held electric tool are respectively provided with external threads and internal thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com