Full-automatic grinder for soybean milk and other drinks

A fully automatic grinding machine and beverage technology, applied in milk substitutes, dairy products, beverage preparation devices, etc., can solve the problems of destroying the nutritional components of food, separation, affecting the normal life of consumers, etc., and achieve the effect of fine food and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

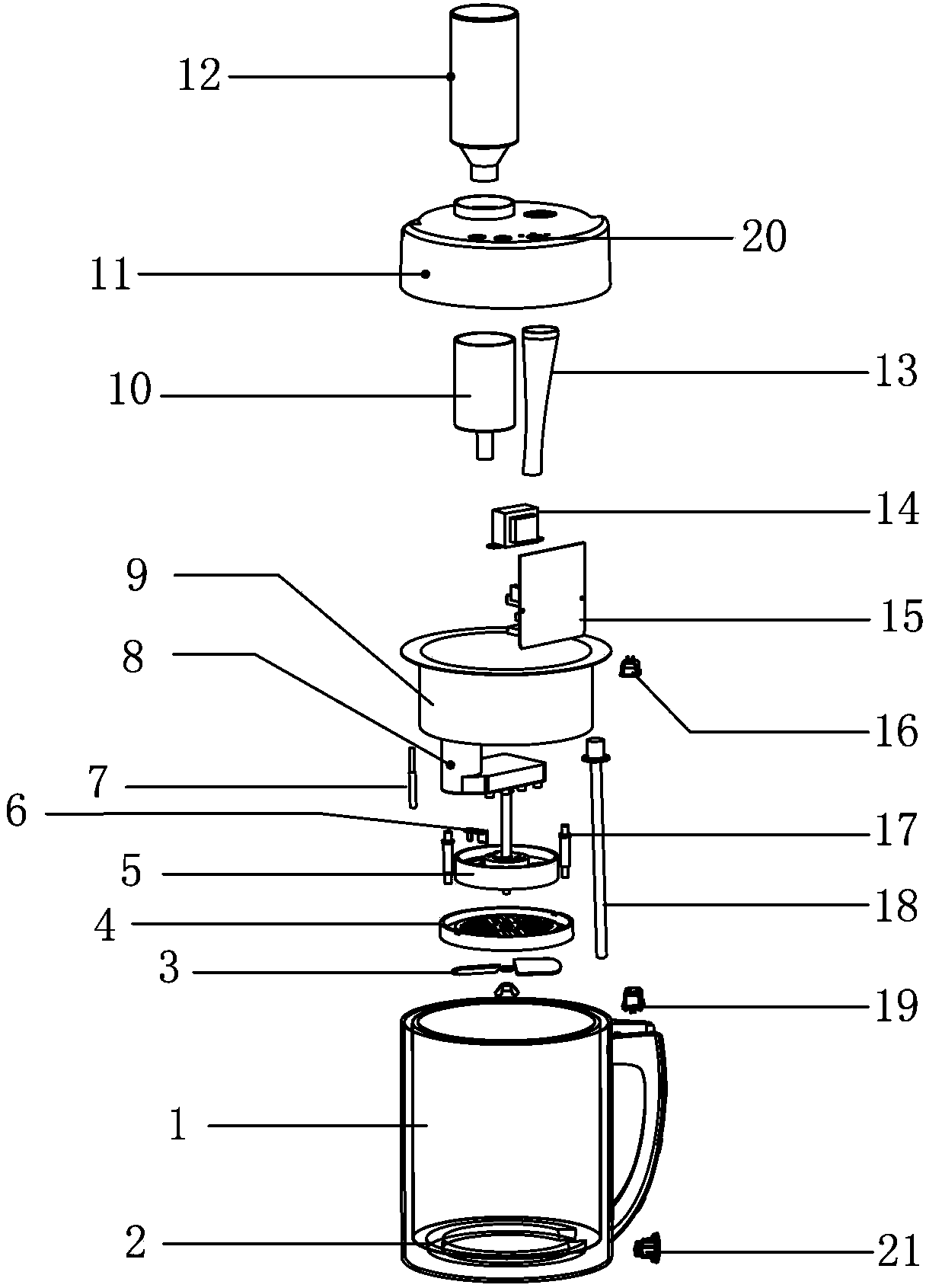

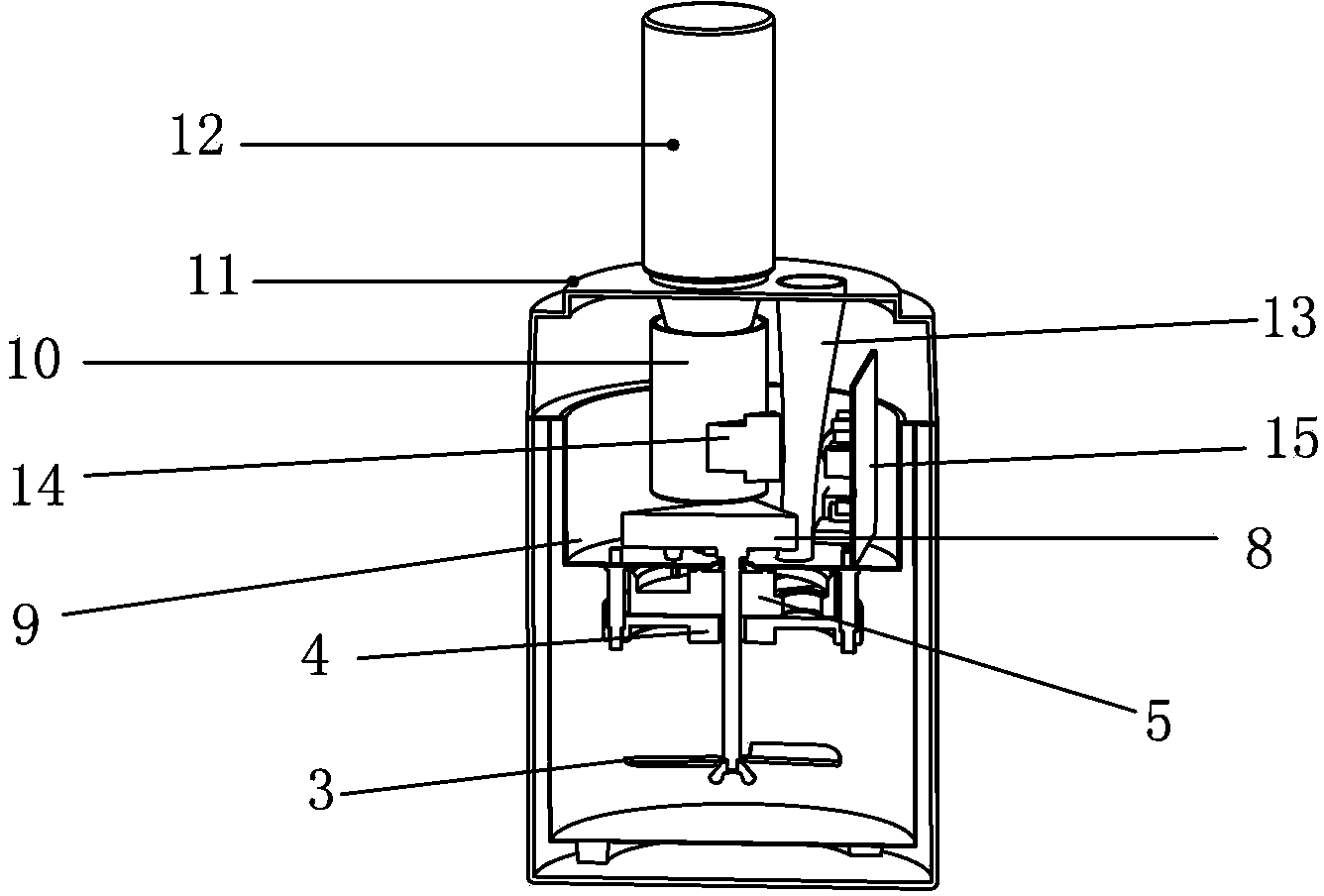

[0029] The fully automatic grinding machine of this embodiment includes a cup body assembly and a machine head assembly.

[0030] The cup body assembly includes: a stainless steel double-layer cup body 1, a heating element 2 arranged at the bottom of the stainless steel double-layer cup body 1, a lower connector 19 arranged at the handle of the stainless steel double-layer cup body 1, and a bottom connector 19 arranged at the bottom of the stainless steel double-layer cup body 1. The power socket 21 on the outer side of the stainless steel double-layer cup body 1 bottom.

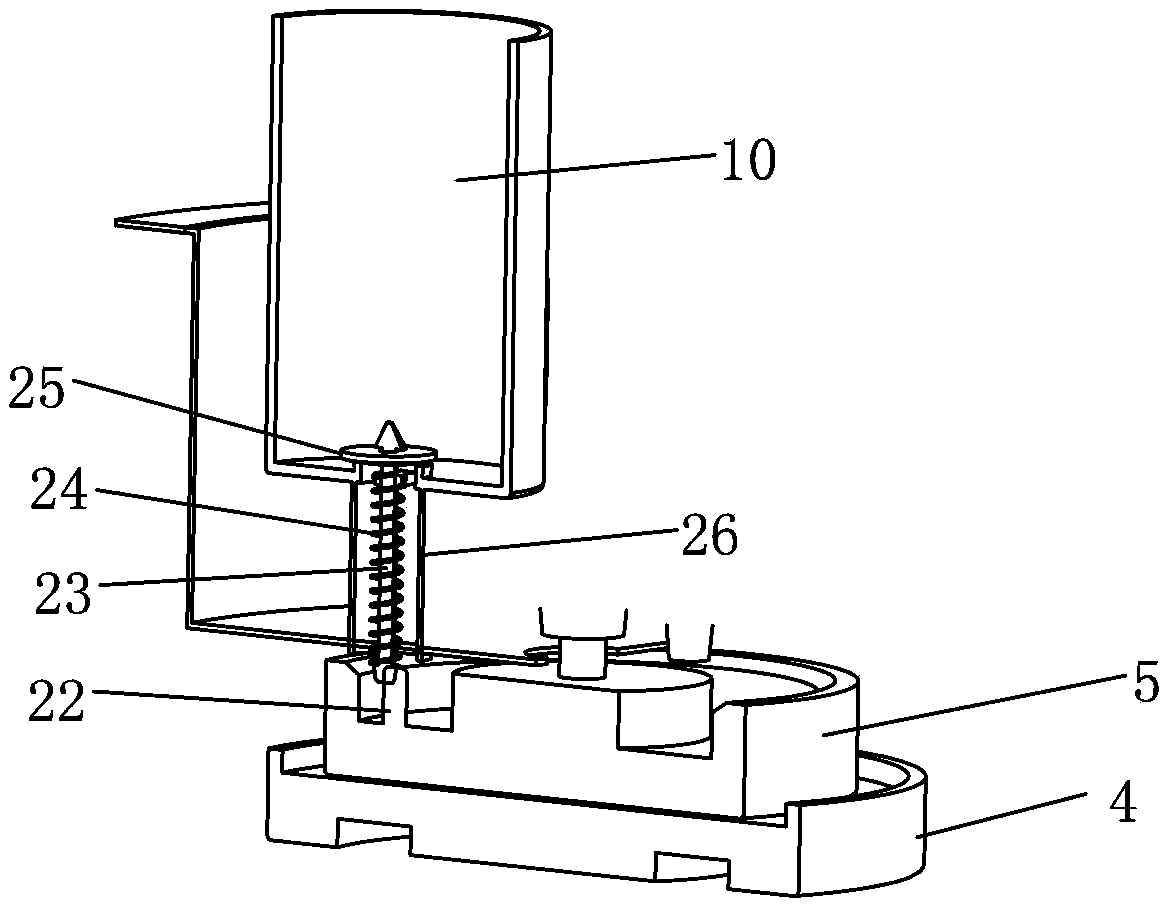

[0031] The head assembly includes: motor base 9, slow motor 8, upper grinding disc 5, lower grinding disc 4, temperature sensor 18, anti-overflow sensor 7, food stirrer 6, water storage tank 10, face cover 11, Detachable water tank 12, feeding trough 13, transformer 14, intelligent circuit board 15, upper connector 16, screw rod 17, stirring blade 3, and display board button 20 from the upper cover 11; the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com