Cover glass laminated structure and processing method thereof

A laminated structure, cover glass technology, applied in glass/slag layered products, chemical instruments and methods, coatings, etc., can solve problems such as poor appearance, reduce production costs, and ensure the effect of appearance yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

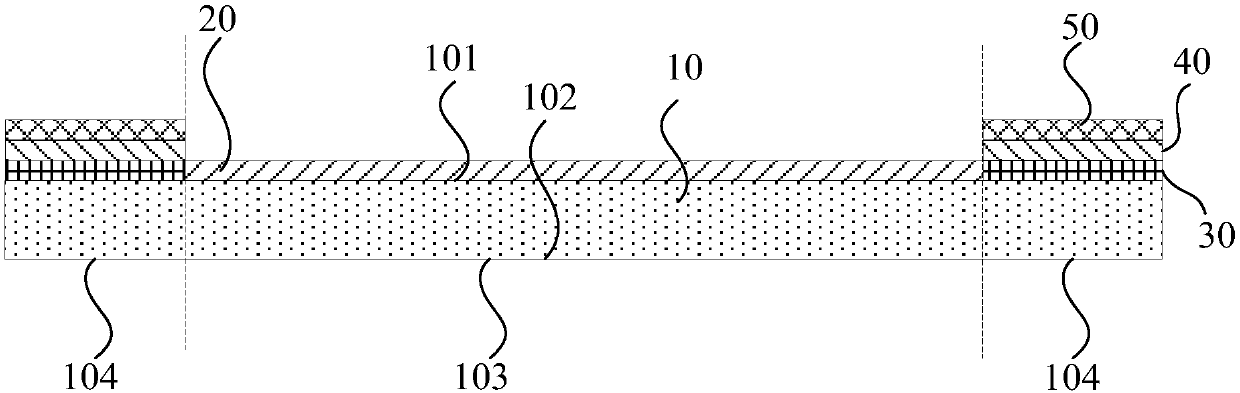

[0036] like figure 1 As shown, a cover glass laminated structure provided by an embodiment of the present invention can be used as a display case of an electronic product with a touch function, and these electronic products include but are not limited to mobile phones, cameras, tablet computers, terminal displays, etc. .

[0037] The cover glass laminated structure includes a glass substrate 10 , a UV glue layer 20 , a UV texture layer 30 , a coating layer 40 and a cover ink layer 50 .

[0038] The glass substrate 10 has opposite first and second surfaces 101 and 102 . In this embodiment, the glass substrate 10 is flat glass, and it is not excluded that the glass substrate 10 has at least part of a curved surface in some other embodiments. The glass substrate 10 can be in the shape of a rectangle, a circle, a square, etc. according to the applied electronic products.

[0039] In this embodiment, the first surface 101 of the glass substrate 10 is a surface facing the interio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com