Cover plate glass stacked structure and processing method thereof

A technology of laminated structure and cover glass, which is applied in the input/output process of instruments, electrical digital data processing, and data processing, etc., can solve the problems of poor vision, wrinkles of curved cover glass, deformation of decorative film, etc., to ensure the appearance Yield, improve yield, reduce the effect of direct exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

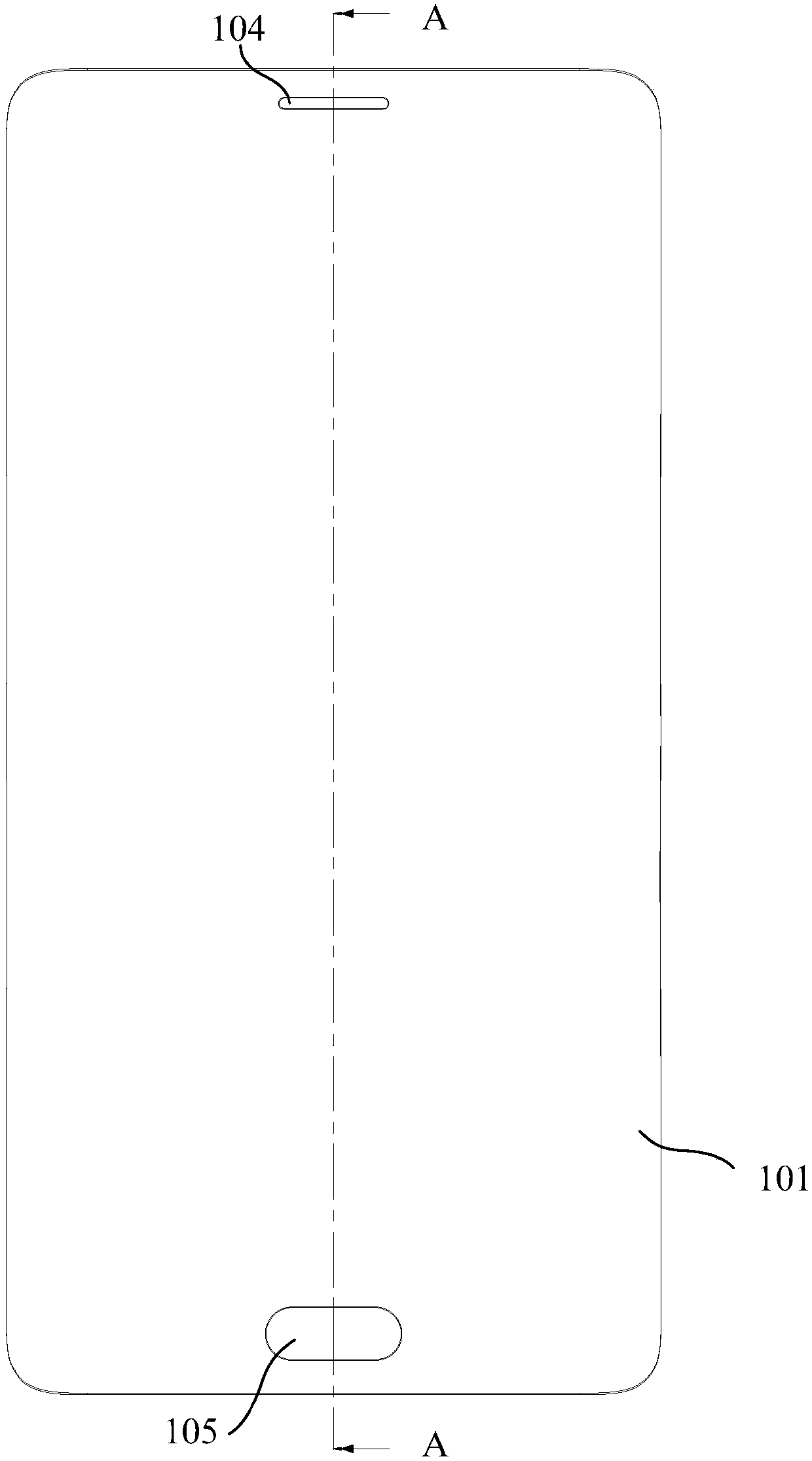

[0045] The cover glass laminated structure provided by the present invention can be used as a display case of electronic products with touch function, such electronic products include but not limited to mobile phones, cameras, tablet computers, terminal displays and the like.

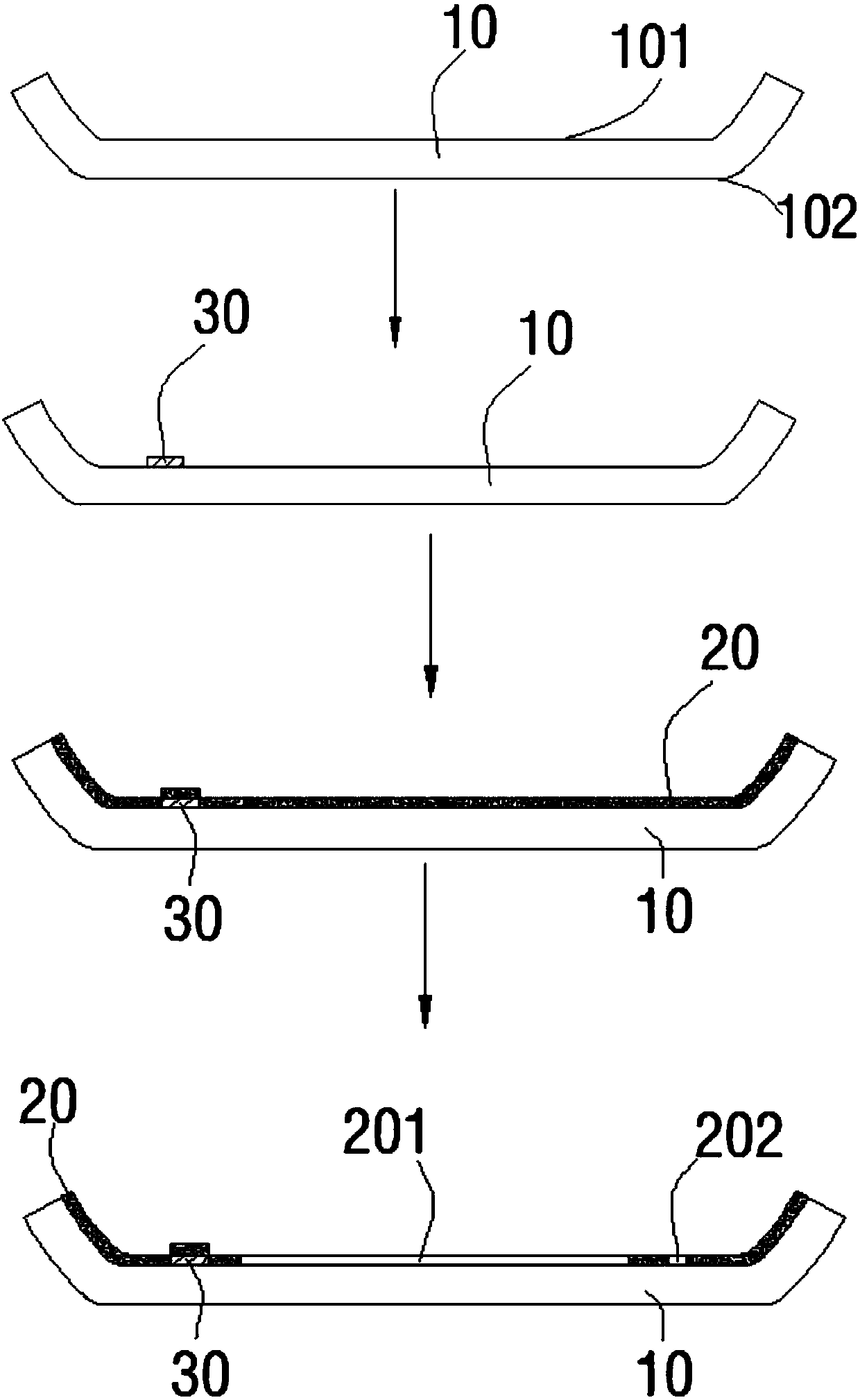

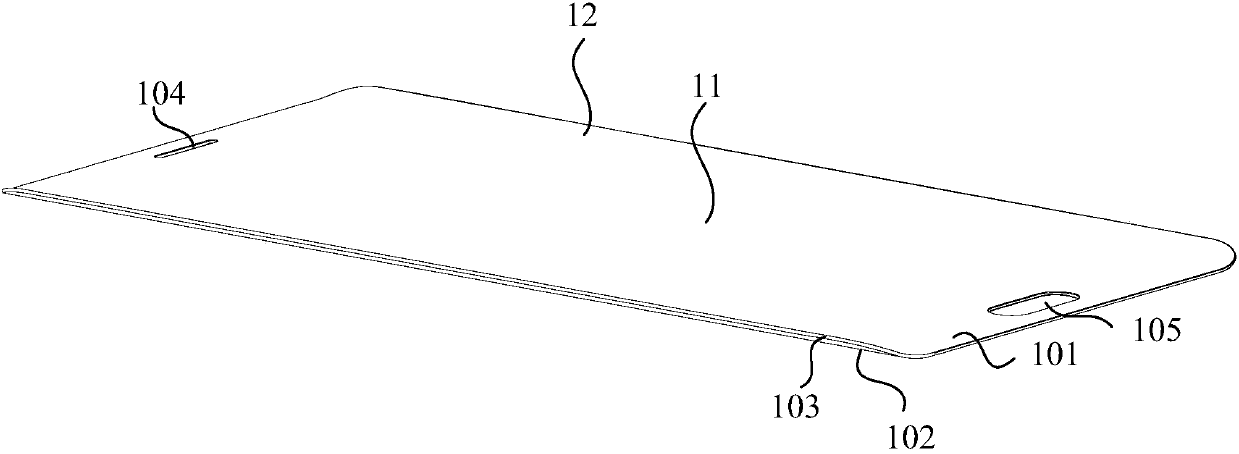

[0046] figure 1 The structure obtained in each step during the processing of the cover glass laminated structure provided by an embodiment of the present invention is shown. The cover glass laminated structure includes a glass substrate 10 , a decoration layer 30 , a photoresist ink layer 20 and a cover ink layer (not shown).

[0047] The glass substrate 10 has opposite first and second surfaces 101 and 102 . In this embodiment, the glass substrate 10 has at least a part of the curved surface, and it is not excluded that the glass substrate 10 is flat glass in some other embodiments. The glass substrate 10 can be in the shape of a rectangle, a circle, a square, etc. according to the applied electronic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com