Pre-plating treatment agent and pre-plating treatment process

A technology for electroplating pretreatment and treatment process, applied in the field of metal surface treatment, can solve the problems of oxide residue, poor adhesion of electroplating layer, affecting electroplating effect, etc., to ensure environmental protection, avoid strong acid pollution, ensure appearance yield and The effect of electroplating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

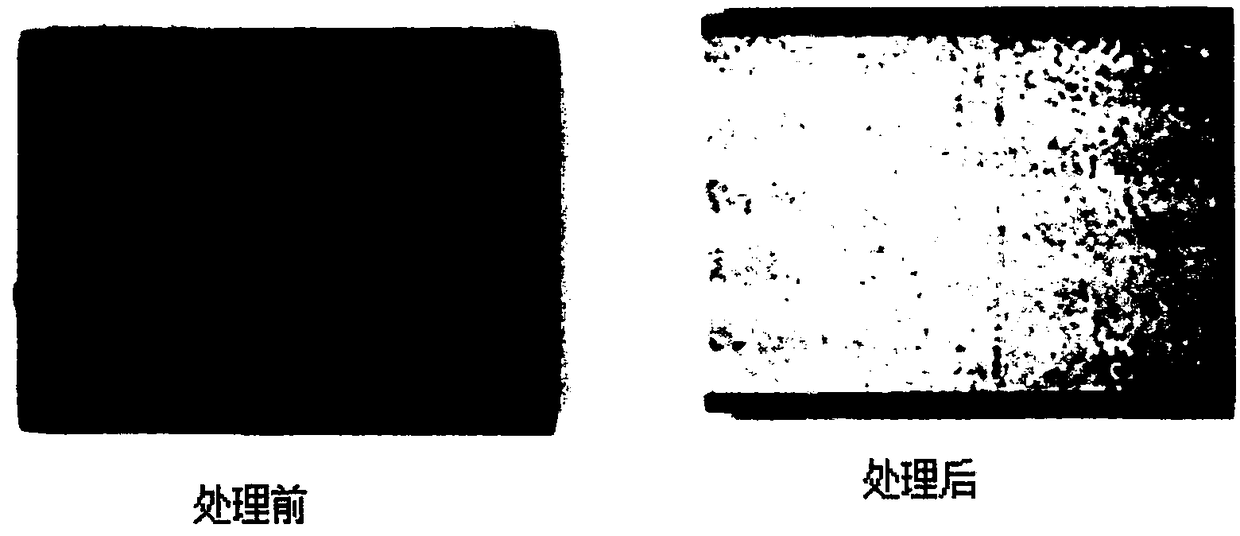

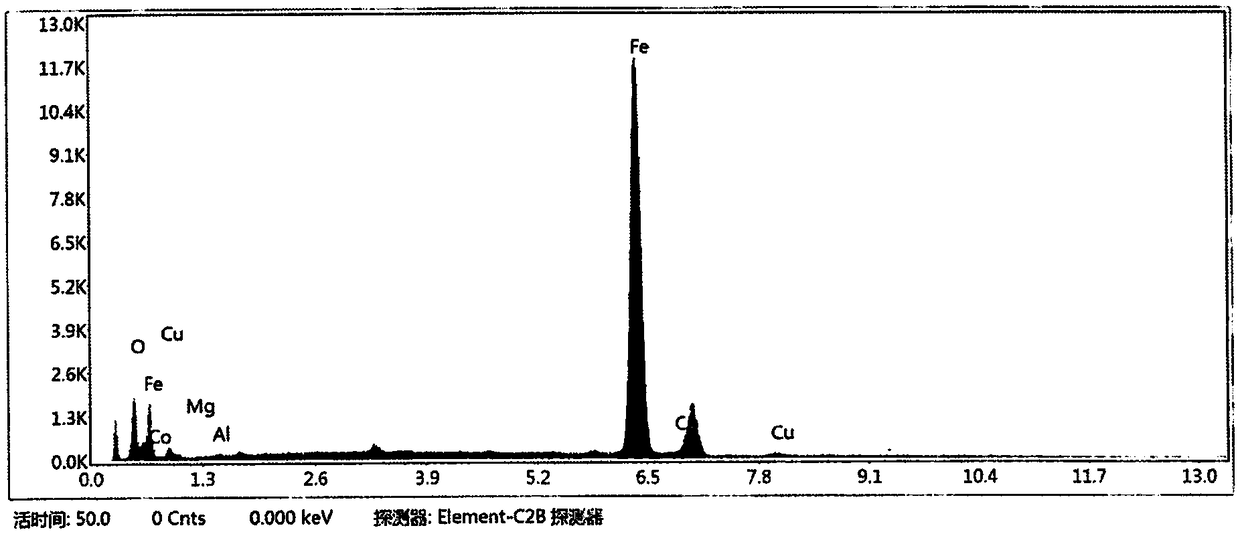

[0046] The substrate to be treated in this embodiment is an iron substrate.

[0047] A kind of electroplating pretreatment process, described treatment process comprises the following steps:

[0048] S100: Use the first treatment agent to soak the substrate to be treated; the specific formula of the first treatment agent is to contain 10g of ammonium fluoride, 60g of oxalic acid and 5g of hydrogen peroxide per liter of water; the soaking time is 20S;

[0049] S200: Use the second treatment agent to perform a second soaking treatment on the substrate treated in step S100; the second treatment agent is a dilute hydrochloric acid solution with a mass concentration of 10%; wherein the second treatment agent is treated with 30% dilute hydrochloric acid. configure. The soaking time in step S200 is 20S.

[0050] S300: Perform cleaning treatment on the base material after the treatment in step S200.

[0051] The substrate processed in step S300 of this embodiment can be subjected t...

Embodiment 2

[0054] The substrate to be treated in this embodiment is an iron substrate.

[0055] A kind of electroplating pretreatment process, described treatment process comprises the following steps:

[0056] S001: Soak the substrate to be treated in an aqueous sodium hydroxide solution with a mass concentration of 30 g / L for 10 seconds;

[0057] S002: cleaning the substrate after step S001 to remove the sodium hydroxide solution on the surface of the substrate;

[0058] S100: Use the first treatment agent to soak the substrate treated in step S002; wherein the specific formula of the first treatment agent contains 20g of ammonium fluoride, 40g of oxalic acid and 20.26g of hydrogen peroxide per liter of water; the soaking time is 30S ;

[0059] S200: Use the second treatment agent to soak the substrate treated in step S100 for a second time; the second treatment agent is a dilute hydrochloric acid solution with a mass concentration of 7%; wherein the second treatment agent is treated...

Embodiment 3

[0091] The substrate to be treated in this embodiment is an iron substrate.

[0092] A kind of electroplating pretreatment process, described treatment process comprises the following steps:

[0093] S001: Soak the base material to be treated with an aqueous solution of sodium hydroxide having a mass concentration of 40 g / L, and the soaking time is 10 seconds;

[0094] S002: cleaning the substrate after step S001 to remove the sodium hydroxide solution on the surface of the substrate;

[0095] S100: Use the first treatment agent to soak the substrate treated in step S002; wherein the specific formula of the first treatment agent contains 40g of ammonium fluoride, 20g of oxalic acid and 30g of hydrogen peroxide per liter of water; the soaking time is 40S;

[0096] S200: Use the second treatment agent to perform a second soaking treatment on the substrate treated in step S100; the second treatment agent is a dilute hydrochloric acid solution with a mass concentration of 15%; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com