A kind of polypropylene composite material suitable for electroplating reaction and preparation method thereof

A composite material and polypropylene technology, applied in the field of polypropylene composite material and its preparation, can solve the problems of complicated process, unsatisfactory hydrophilicity and coating gloss of polypropylene composite material, and high production cost, and achieves simple production process, The effect of easy pre-plating treatment and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

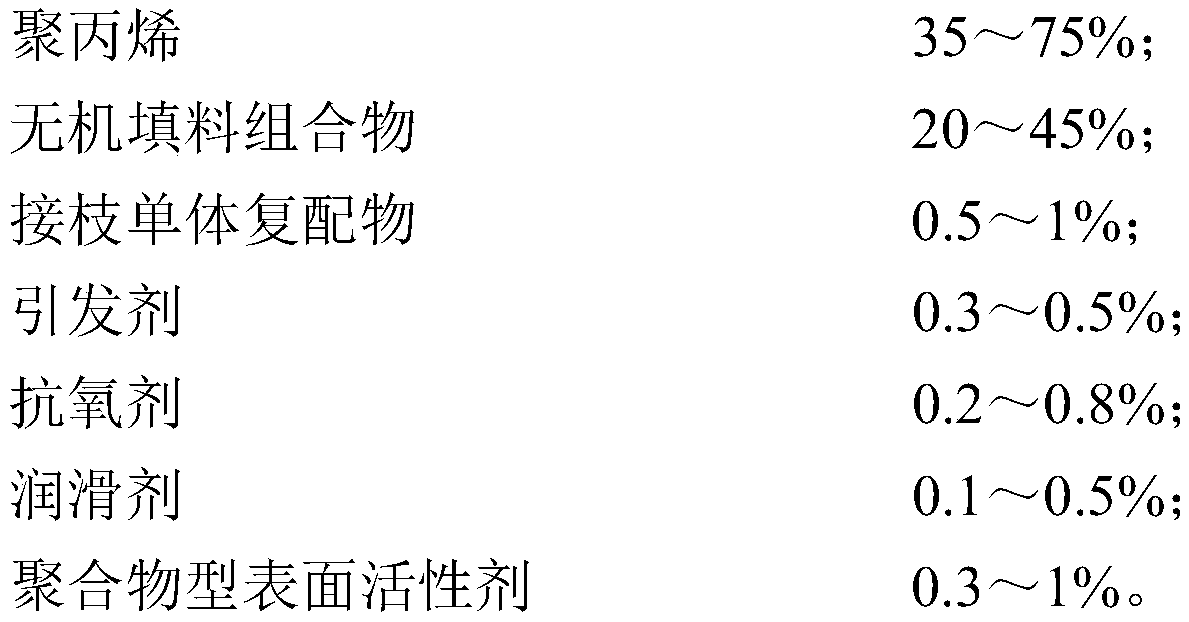

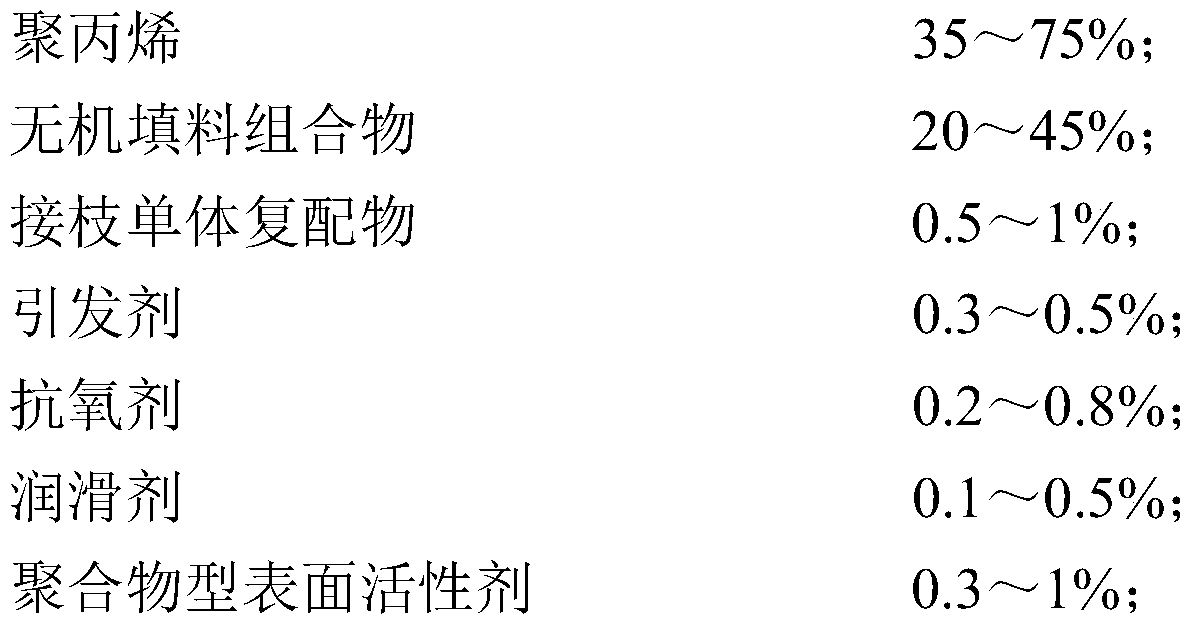

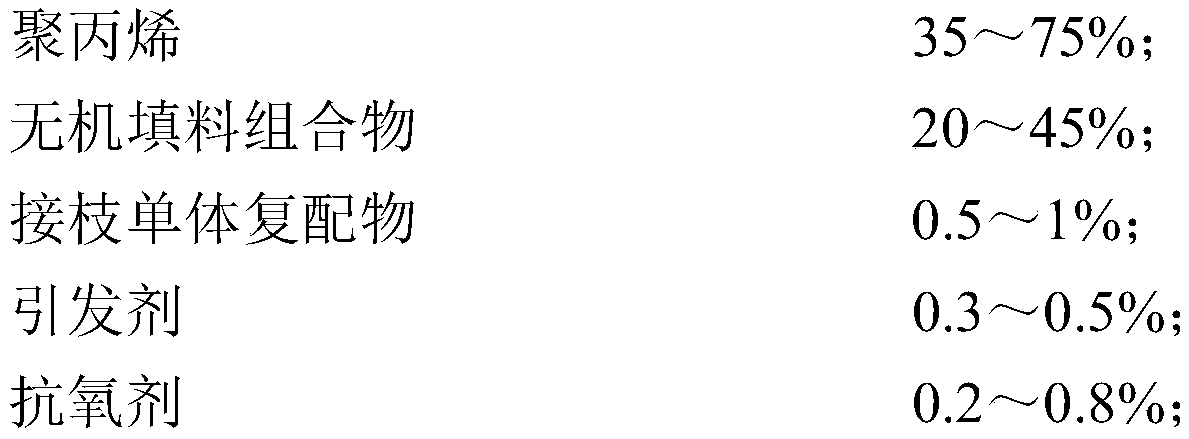

[0030] A polypropylene composite material suitable for electroplating reactions comprising, by weight percent:

[0031]

[0032]

[0033] The polypropylene in this example is homopolypropylene, and its melt index at a temperature of 230°C and a test load of 2.16kg is 2-4g / 10min; the inorganic filler composition is calcium carbonate and calcium carbonate with a particle size of 3-10 microns. Two mixtures of barium sulfate; the mixing ratio is calcium carbonate: barium sulfate = 2:1 by mass ratio. The grafted monomer compound is a compound system of two unsaturated carboxylic acids, and two monomers of glycidyl methacrylate and acrylic acid are used for compounding, wherein glycidyl methacrylate and acrylic acid are grafted The weight ratio of the monomers is 1.5:1 to 2:1 respectively.

[0034] The initiator in the present embodiment is benzoyl peroxide; Antioxidant includes main antioxidant and auxiliary antioxidant, main antioxidant and auxiliary antioxidant are mixed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com