Thyratron transistor valve water-cooling radiator

A technology of water-cooled radiators and thyristor valves, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of difficult system maintenance, large investment at one time, and low cooling efficiency, and achieve increased heat dissipation area, Reduced maintenance and reduced thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

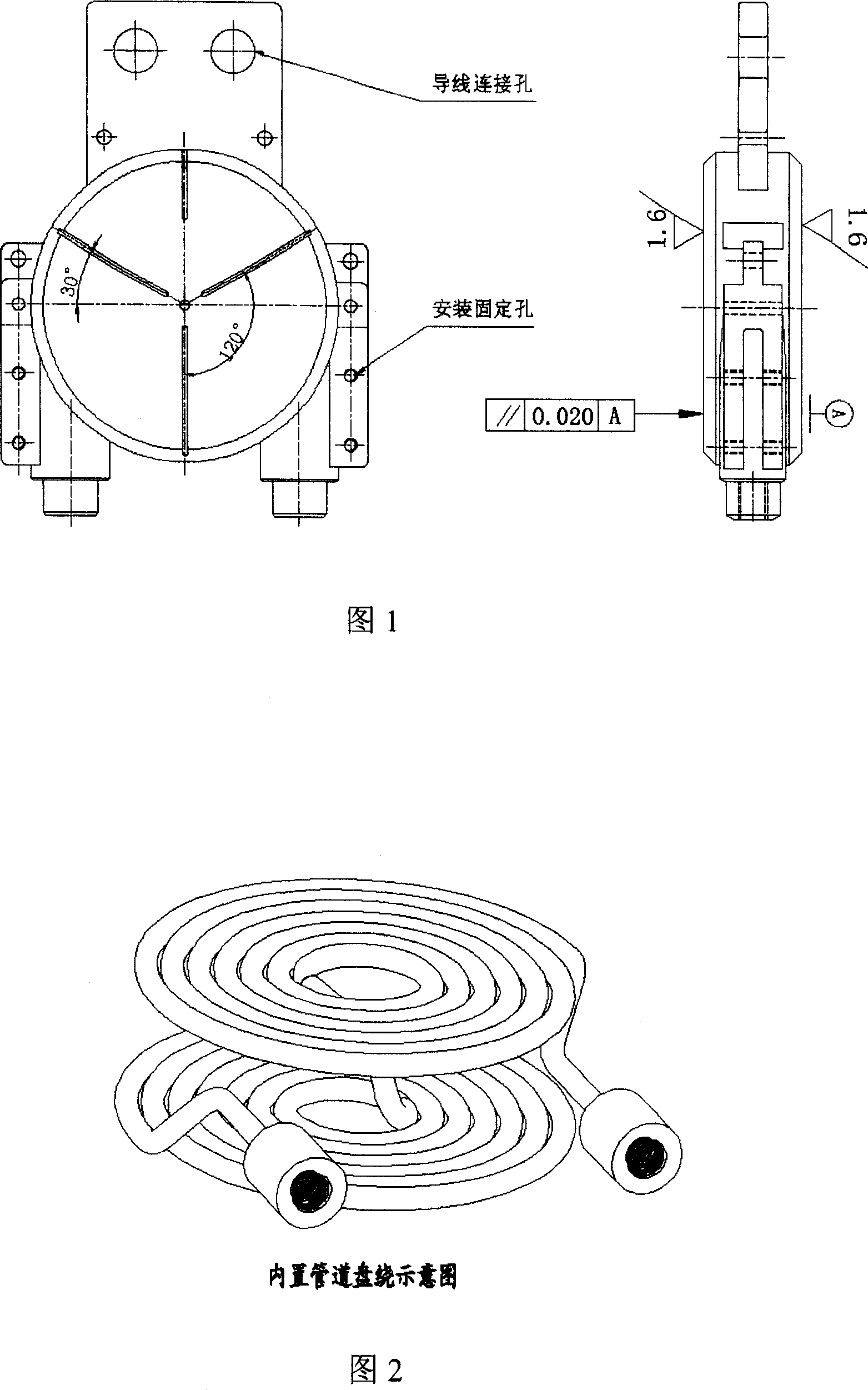

[0030] See Figure 1. The thyristor valve water-cooled radiator adopts a flat surface contact heat transfer structure. The parallelism of the two tables of the water-cooled radiator is within 0.02mm, and the surface roughness of the two tables is below 1.6μm, which can improve the microscopic heat transfer area and heat transfer efficiency. , At the same time, it can ensure that the number of crimping thyristor valves and water-cooled radiators reaches more than 20 strings.

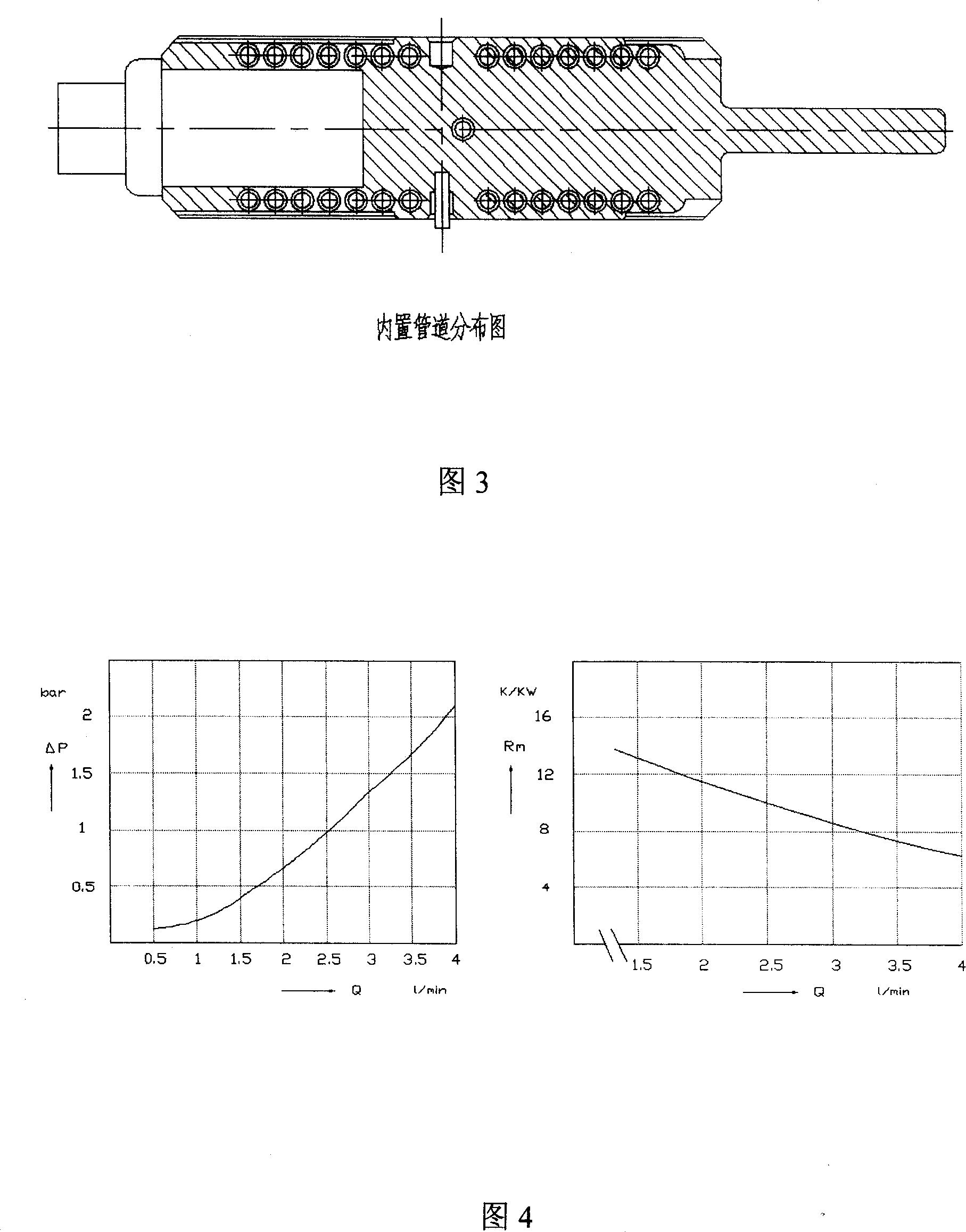

[0031] The interface of the cooling water pipe is one in and one out, so as to reduce the number of water distribution pipes at the interface, simplify the layout and facilitate installation.

[0032] The built-in pipe of the water-cooling radiator is close to the table to shorten the heat transfer stroke and dissipate heat in time.

[0033] There are dedicated wire connection holes and installation fixing holes outside the table of the water-cooling radiator.

[0034] The built-in pipes of the water-cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com