Method for aluminum alloy electroplating powder cloud nickel composite coating

A composite coating and aluminum alloy technology, applied in coatings, electrolytic coatings, etc., can solve the problems of poor surface corrosion resistance, large consumption of electroplating materials, and high discharge of electroplating wastewater, so as to shorten production time and simplify the electroplating process , The effect of electroplating process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

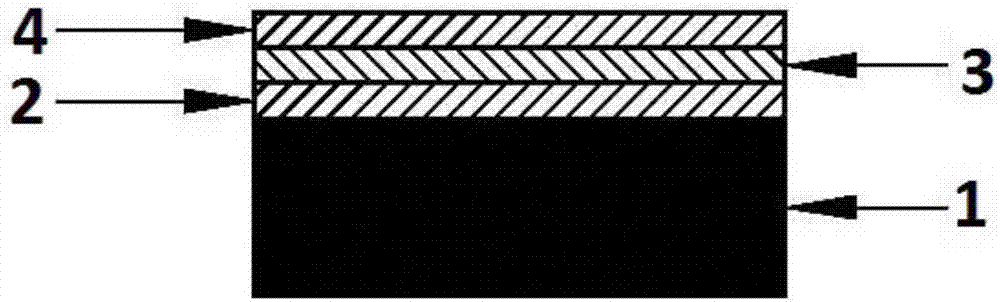

[0038] see figure 1 , an aluminum alloy electroplating powder mist nickel composite coating structure, comprising an aluminum alloy substrate 1 and a composite coating, the composite coating includes a replacement zinc coating 2, a bottom nickel coating 3 and a powder mist nickel coating 4; the surface of the aluminum alloy substrate 1 The composite coatings are made according to the following coating sequence: replacement zinc coating 2, bottom nickel coating 3, powder mist nickel coating 4, which are composited by electroplating.

[0039] A method for aluminum alloy electroplating powder mist nickel composite coating, comprising the following steps:

[0040] (1) Pre-treatment of electroplating; including the following steps:

[0041] 1) Hot water degreasing and degreasing: The composition of the hot water degreasing and degreasing tank liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com