Scribing method

A scribing and scribing technology, which is applied in laser welding equipment, electrical components, circuits, etc., can solve problems such as insufficient ablation zone width, fragmentation of LED epitaxial wafers, excessive stress, etc., to ensure appearance yield and reduce fragmentation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

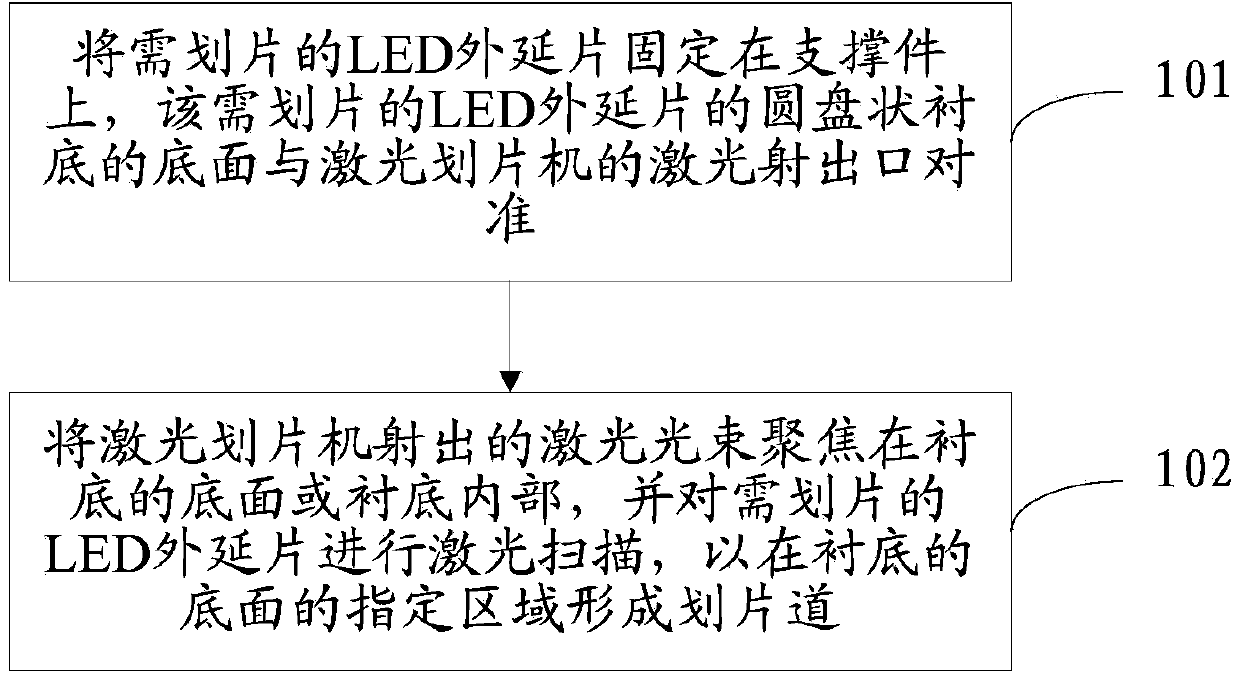

[0044] The embodiment of the present invention provides a scribing method, see figure 1 , the method includes:

[0045] Step 101: Fix the LED epitaxial wafer to be diced on the support member, and align the bottom surface of the disk-shaped substrate of the LED epitaxial wafer to be diced with the laser injection port of the laser scribing machine.

[0046] As an optional mode of this embodiment, the LED epitaxial wafer to be diced can be fixed on the support in such a way that the bottom surface of the disc-shaped substrate of the LED epitaxial wafer is horizontally upward, and the support is located on the laser scribing machine. Right below the laser exit.

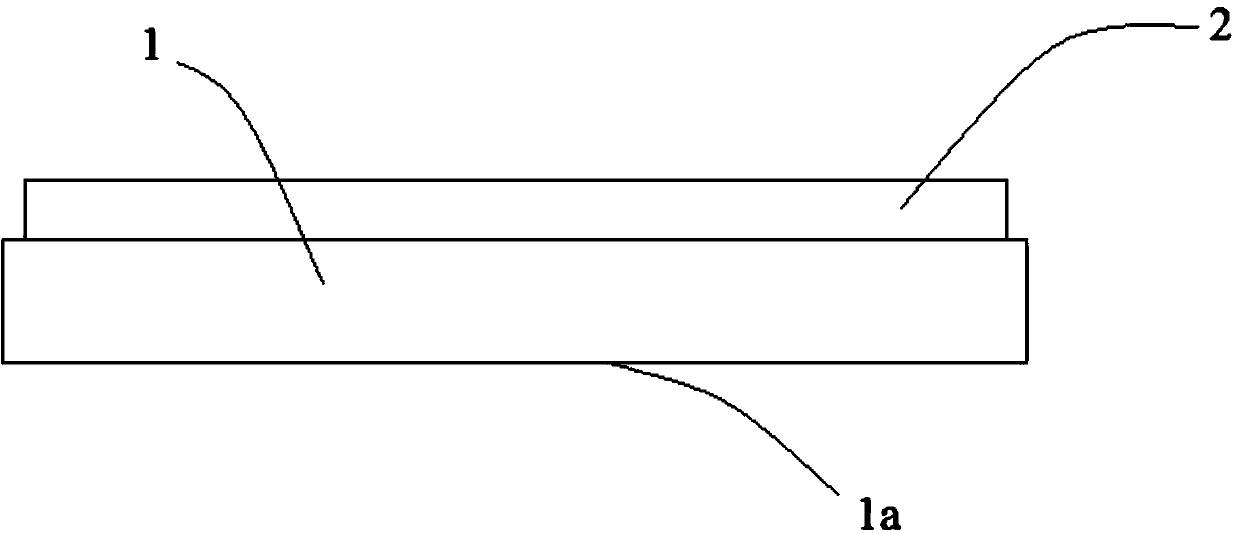

[0047] see figure 2, the LED epitaxial wafer is composed of a substrate 1 and an LED chip array 2 grown on the substrate 1 . The substrate 1 is disc-shaped, and the material of the substrate 1 can be sapphire or silicon carbide. In the embodiment of the present invention, the bottom surface 1a of the substrate 1 re...

Embodiment 2

[0054] The embodiment of the present invention provides a scribing method, see Figure 4 , the method includes:

[0055] Step 201: Fix the LED epitaxial wafer to be diced on the support, and align the bottom surface of the disk-shaped substrate of the LED epitaxial wafer to be diced with the laser injection port of the laser scribing machine.

[0056] Wherein, the supporting member may be a platform or a bracket.

[0057] Optionally, a protective film may be provided between the LED epitaxial wafer to be diced and the support.

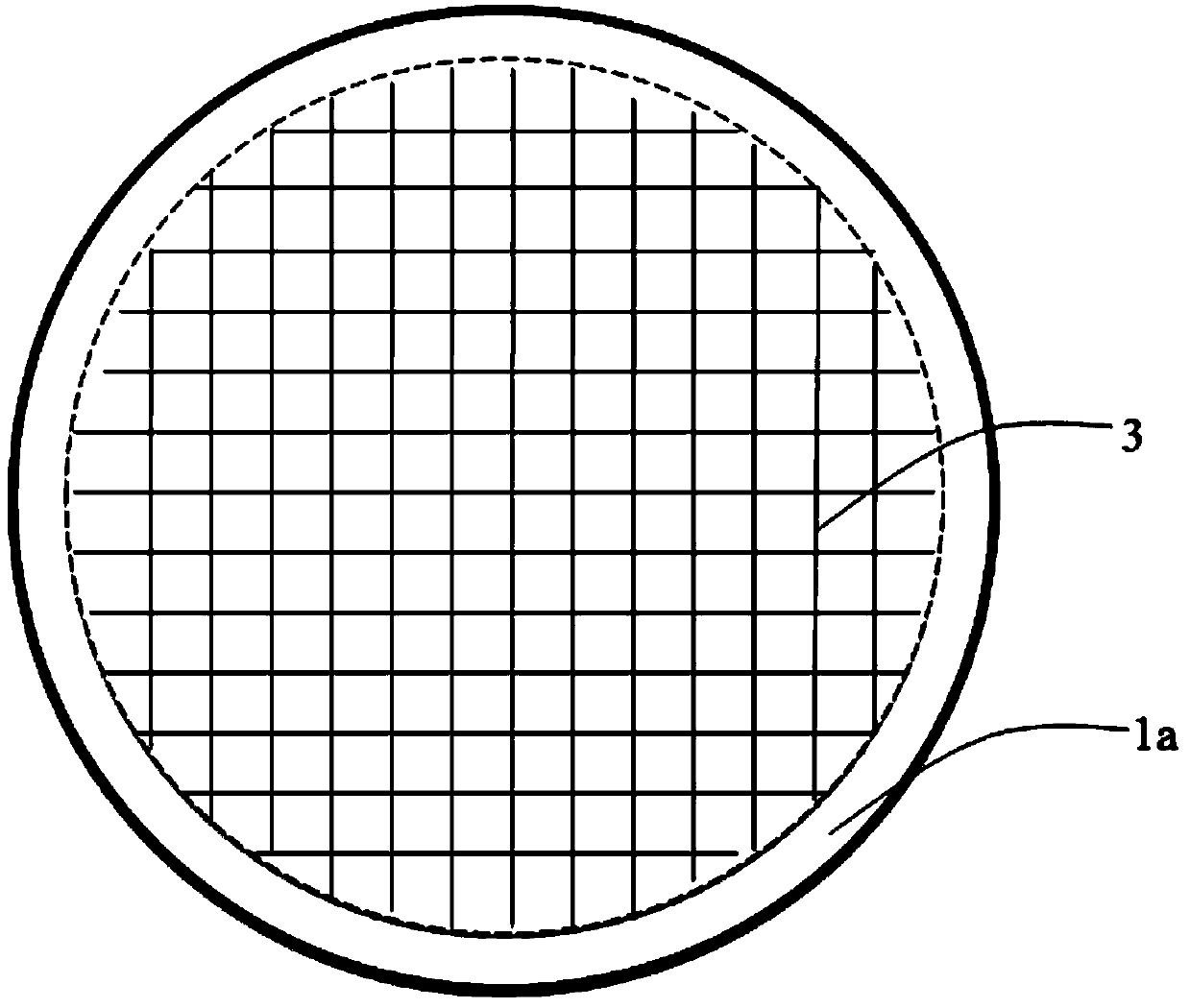

[0058] Step 202: placing a preset tooling on the bottom surface of the substrate, and the preset tooling will cover a designated area of the bottom surface of the substrate.

[0059] Wherein, the specified area is a concentric circle of the bottom surface of the substrate, and the radius of the specified area is smaller than the radius of the bottom surface of the substrate.

[0060] Optionally, the preset tooling may be in the shape of a hollow r...

Embodiment 3

[0074] The embodiment of the present invention provides a scribing method, see Figure 5 , the method includes:

[0075] Step 301: Fix the LED epitaxial wafer to be diced on the support, and align the bottom surface of the disc-shaped substrate of the LED epitaxial wafer to be diced with the laser injection port of the laser scribing machine.

[0076] This step 301 is the same as step 201, and will not be repeated here.

[0077] Step 302: Start the laser scribing machine, and focus the laser beam emitted by the laser scribing machine on the bottom surface of the substrate or inside the substrate, and the laser beam forms spot-like spots on the substrate.

[0078] Step 302 is the same as step 203, and will not be repeated here.

[0079] Step 303 : moving the laser outlet so that the dot-like spots form a plurality of first scribing lanes parallel to each other in a designated area on the bottom surface of the substrate.

[0080] Wherein, the moving direction of the laser inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com