Fast loading-unloading and fixing device for high speed rail cargoes

A fixed device and fast technology, applied in the loading and unloading of railway vehicles, cargo support/secured components, transportation and packaging, etc., can solve the problems of low loading and unloading efficiency, limited parking time for high-speed rail, and inability to make full use of the interior space of the carriage. The effect of meeting placement requirements and efficient loading and unloading requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

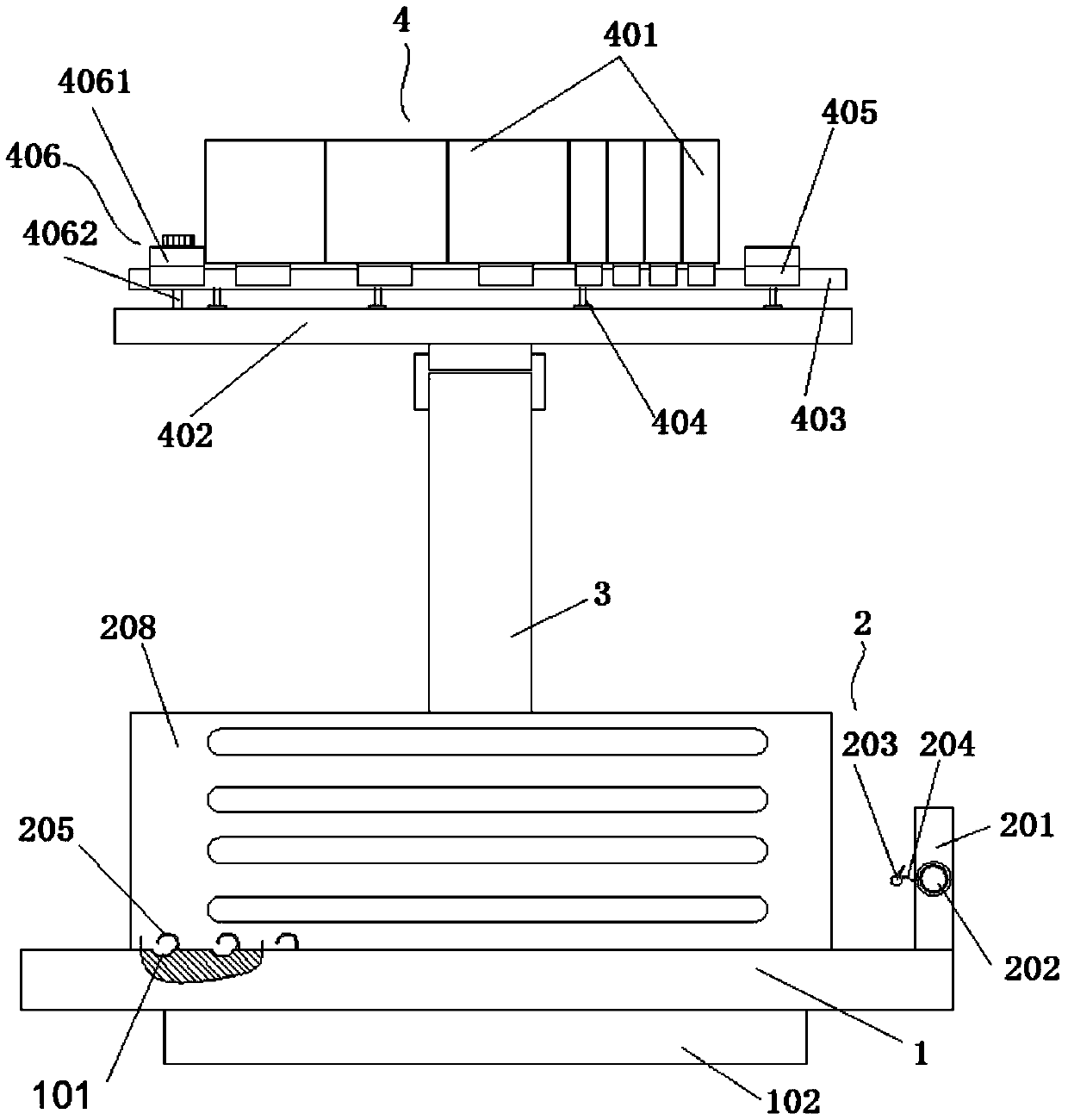

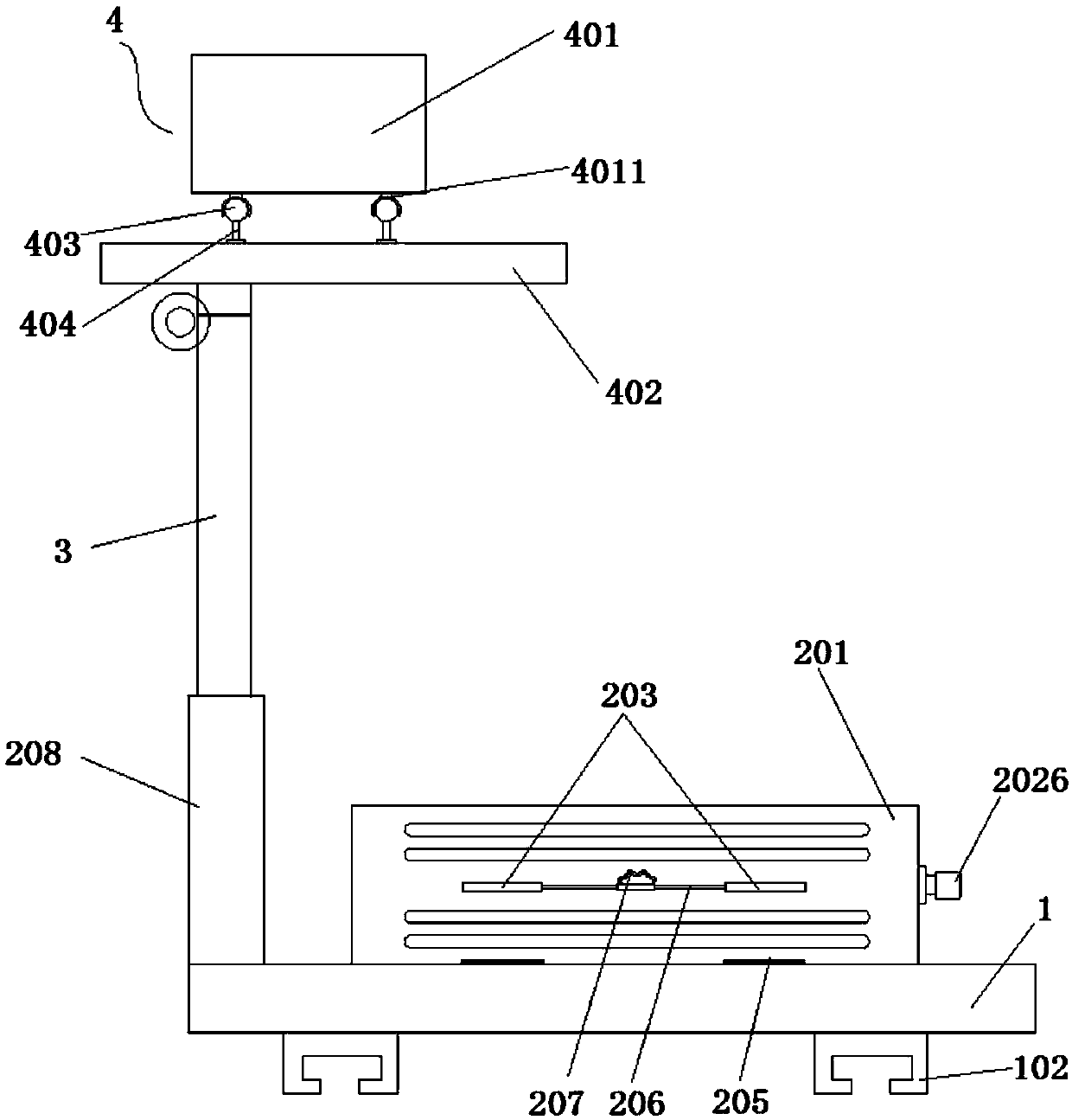

[0043] figure 1 , figure 2 Disclosed in is a fast loading and unloading fixture for high-speed rail cargo, including a transmission device, a first placement plate 1, a fast fastening device 2 for heavy objects and a placement device 4 for light objects. The first placement plate 1 is installed on the transmission device and connected with the transmission device Sliding fit, the fast fast fixing device 2 for heavy objects is installed on the first placement plate 1 , and the fast fixing device 4 for light objects is installed above the fast fastening device 2 for heavy objects through the support plate 3 .

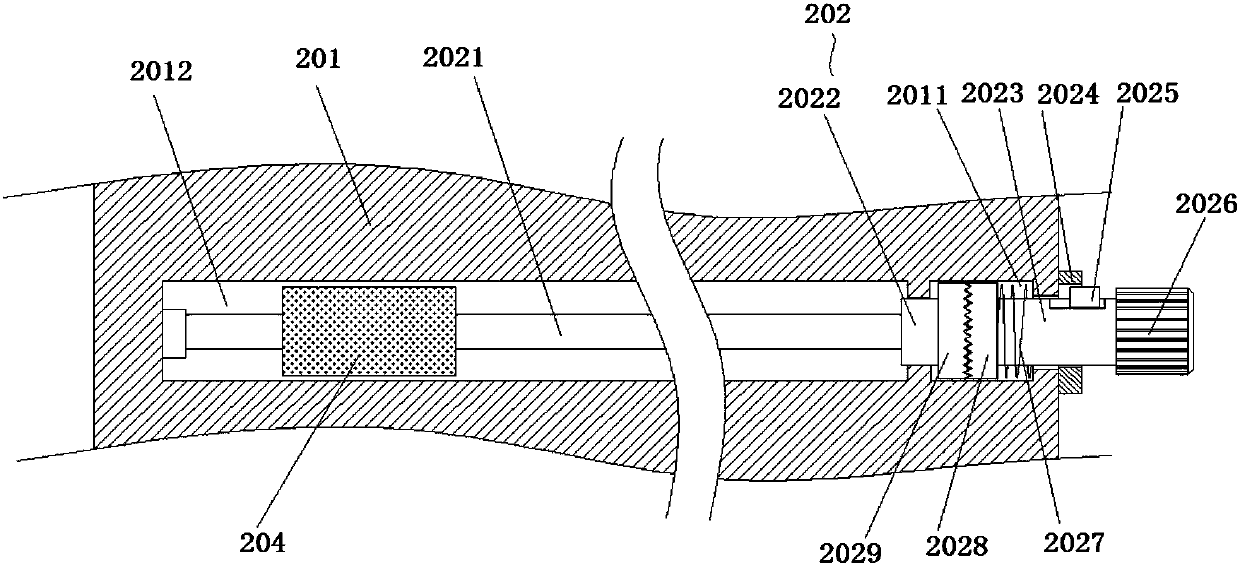

[0044] The heavy fast fixing device 2 includes a first baffle 201 , an anti-loosening device 202 , a fixing rod 203 , and an arc-shaped fixing frame 205 , and the first baffle 201 is fixedly installed on one end of the first placement plate 1 , the anti-loosening device 202 is installed in the first baffle 201, and two sets of elastic bands 204 are wound on the anti-loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com