Shading tape and display device

A technology of shading tape and tape, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of reliability test wrinkles, achieve good creep and stability, improve product yield, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

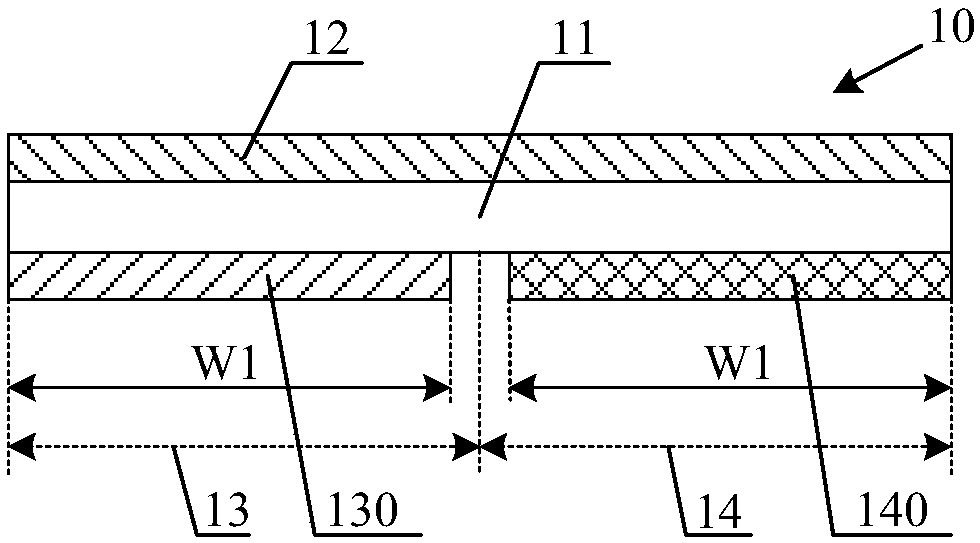

[0036] figure 1 It is a structural schematic diagram of the light-shielding tape according to the first embodiment of the present invention. from figure 1 It can be seen from the figure that the light-shielding adhesive tape 10 includes an adhesive tape body 11 and a first adhesive layer 12 disposed on the first surface of the adhesive tape body 11 . The second surface of the adhesive tape body 11 facing away from the first surface has a first region 13 and a second region 14 that do not intersect each other. The second adhesive layer 130 is disposed in the first area 13 , and the third adhesive layer 140 is disposed in the second area 14 , and the third adhesive layer 140 has creepability and non-transferability. figure 1 The first area 13 and the second area 14 shown in fig.

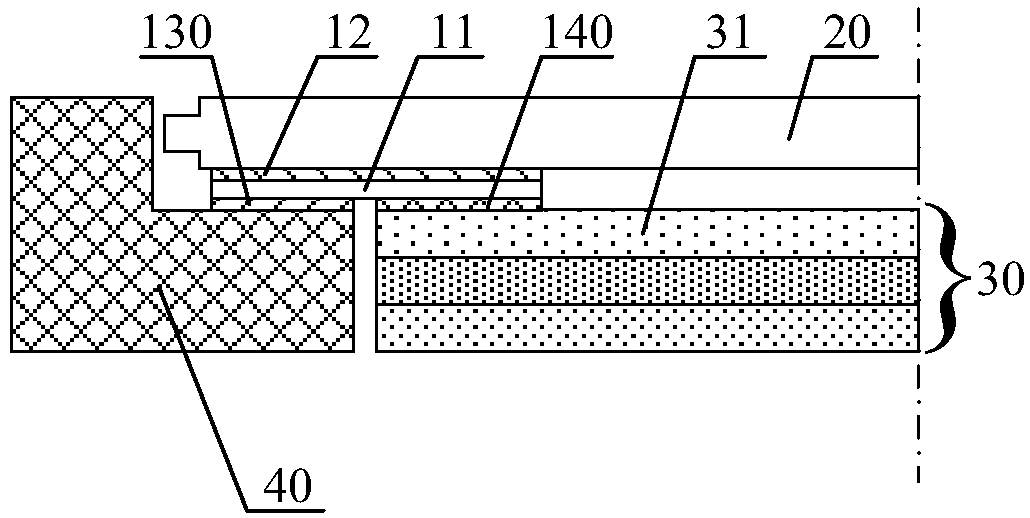

[0037] figure 2 It is a schematic structural diagram of a display device using a light-shielding tape according to the first embodiment of the present invention. When the light-shielding tape 10 ...

no. 2 example

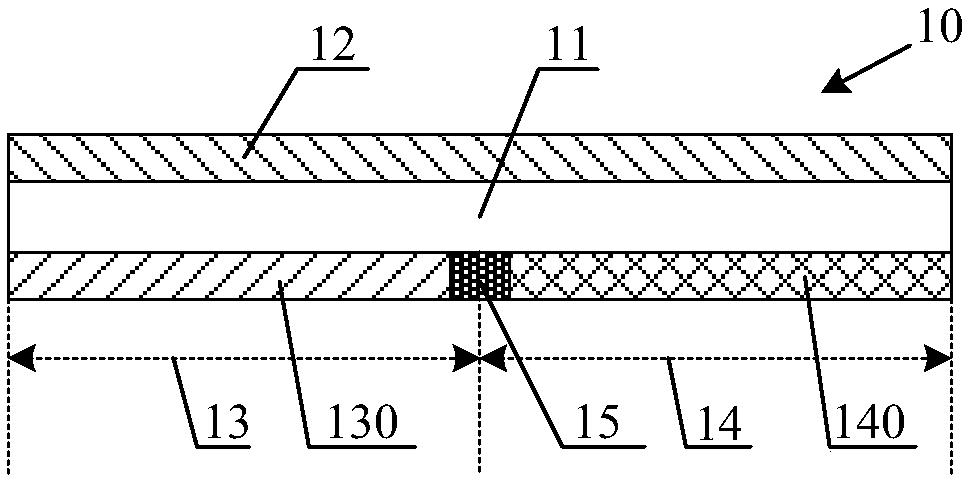

[0044] image 3 It is a schematic structural diagram of the light-shielding adhesive tape according to the second embodiment of the present invention. This embodiment is an extension of the first embodiment, and the main structure of the light-shielding tape in this embodiment is the same as that of the first embodiment. In this embodiment, a light-blocking tape 15 is disposed between the second surface of the adhesive tape body 11 and between the second adhesive layer 130 and the third adhesive layer 140 .

[0045] like figure 2 As shown, when the light-shielding tape of the first embodiment is applied to the display device, since there is a certain gap between the plastic frame 40 and the backlight module 30, there will be a gap between the plastic frame 40 and the backlight module 30 on the second surface of the light-shielding tape. Gap area between groups of 30. The gap area is located between the second adhesive layer 130 and the third adhesive layer 140 . In actual...

no. 3 example

[0047] Figure 4 It is a schematic structural diagram of a display device according to the third embodiment of the present invention. from Figure 4 It can be seen from the figure that the display device includes a plastic frame 40, a backlight module 30 disposed on the same side as the plastic frame 40, and a display panel 20 located above the backlight module 30, and the display device also includes the above-mentioned light-shielding tape 10, The light-shielding tape 10 is sandwiched between the plastic frame 40 , the backlight module 30 and the display panel 20 . Wherein, the second surface of the adhesive tape body 11 faces the plastic frame 40 and the backlight module 30, the surface of the plastic frame 40 is pasted to the second adhesive layer 130, the surface of the backlight module 30 is pasted to the third adhesive layer 140, and the surface of the display panel 20 The surface is pasted to the first adhesive layer 12 .

[0048] Those skilled in the art understand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com