Steel strand finished cable

A steel strand and finished product technology, which is applied in the field of steel strand finished cables, can solve the problems that the anchoring quality cannot meet the ideal requirements of the design, the difficulty of increasing the corrosion resistance of the external thread, and the length of the cable body are limited, etc., so as to achieve good anchoring quality and simplified Construction requirements, effect of axial displacement reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

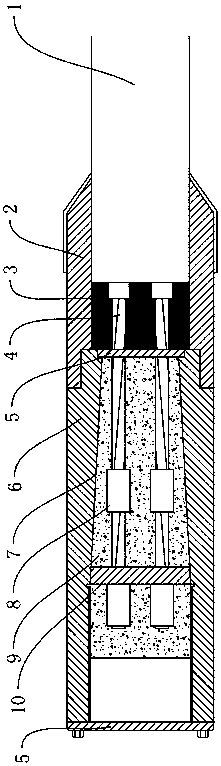

[0019] Embodiment 1: a kind of steel strand finished cable (see figure 1 ), including a cable body 1 stranded by multiple steel strands 4 and an anchoring structure connected to the end of the cable body, each steel strand end is fixed with an extrusion sleeve 8, and the anchoring structure includes an anchoring sleeve 6, setting The support plate 10 in the anchor sleeve and the epoxy cold casting material 9 filled in the anchor sleeve, the end of the extrusion sleeve is in contact with the support plate, and the anchor end sealing cylinder 2 is sleeved outside the cable body, and the anchor end sealing cylinder is in contact with the anchor sleeve. The anchor sleeves are connected and fixed, and the sealing cylinder at the anchor end is filled with anti-corrosion polyurethane 3.

[0020] The inside of the anchor sleeve is provided with an anchor hole 7 with both ends transparent. The anchor hole is divided into two parts, one part is a cylindrical part, and the other part is ...

Embodiment 2

[0022] Embodiment 2: A steel strand finished cable, the difference from Embodiment 1 is that the anchor hole is provided with a positioning step near one end of the anchor sleeve, and the positioning step divides the anchor hole into two parts, one part is a tapered part, The other part is a cylindrical part, wherein the small-diameter end of the tapered part is away from the rectangular part of the anchor hole. The outer periphery of the supporting plate is cylindrical, the outer diameter of the outer cylindrical shape of the supporting plate coincides with the inner diameter of the cylindrical part of the anchoring hole, and one side surface of the supporting plate is in contact with the positioning step. Refer to Example 1 for all the other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com