Balance assembly, rotor assembly and compressor

A technology of balancing components and balancing parts, which is applied in the field of compressors and can solve the problems that the compressor balancing weights cannot be used universally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In each following embodiment of the present invention, all take Image 6 The horizontal direction in is the horizontal direction, Image 6 The vertical direction in is described as the vertical direction, which is only for the convenience of describing the structure, and does not limit the structure to be protected by the present invention.

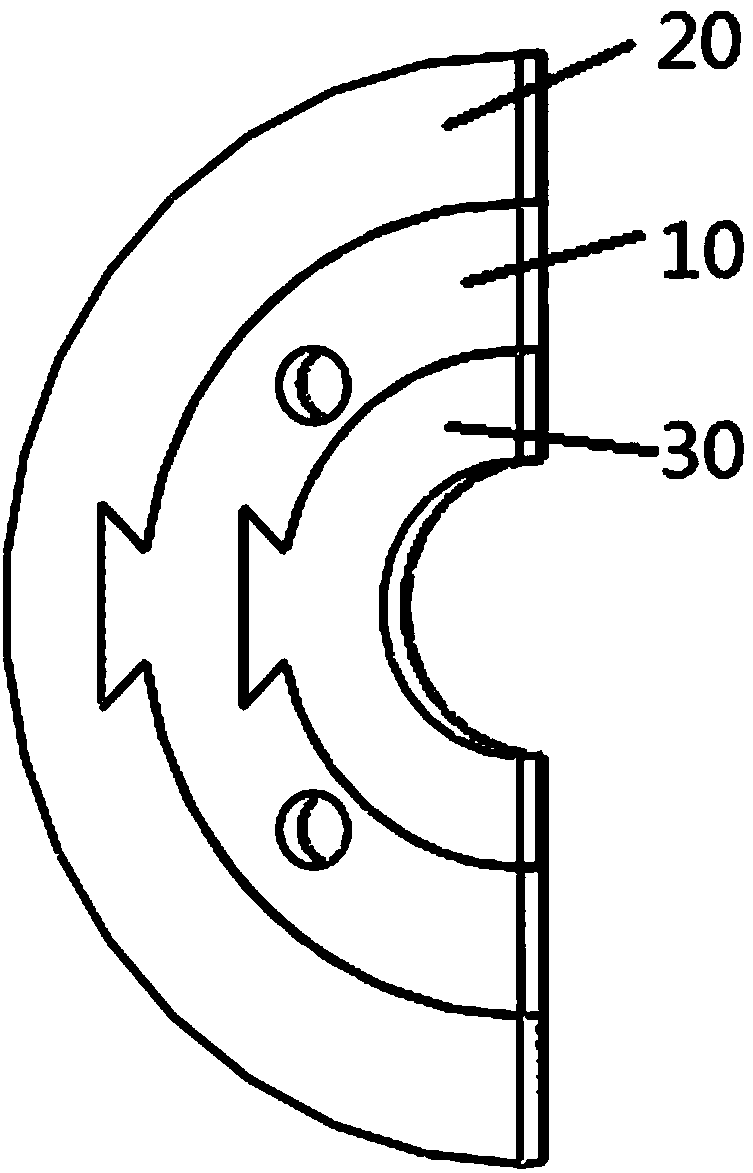

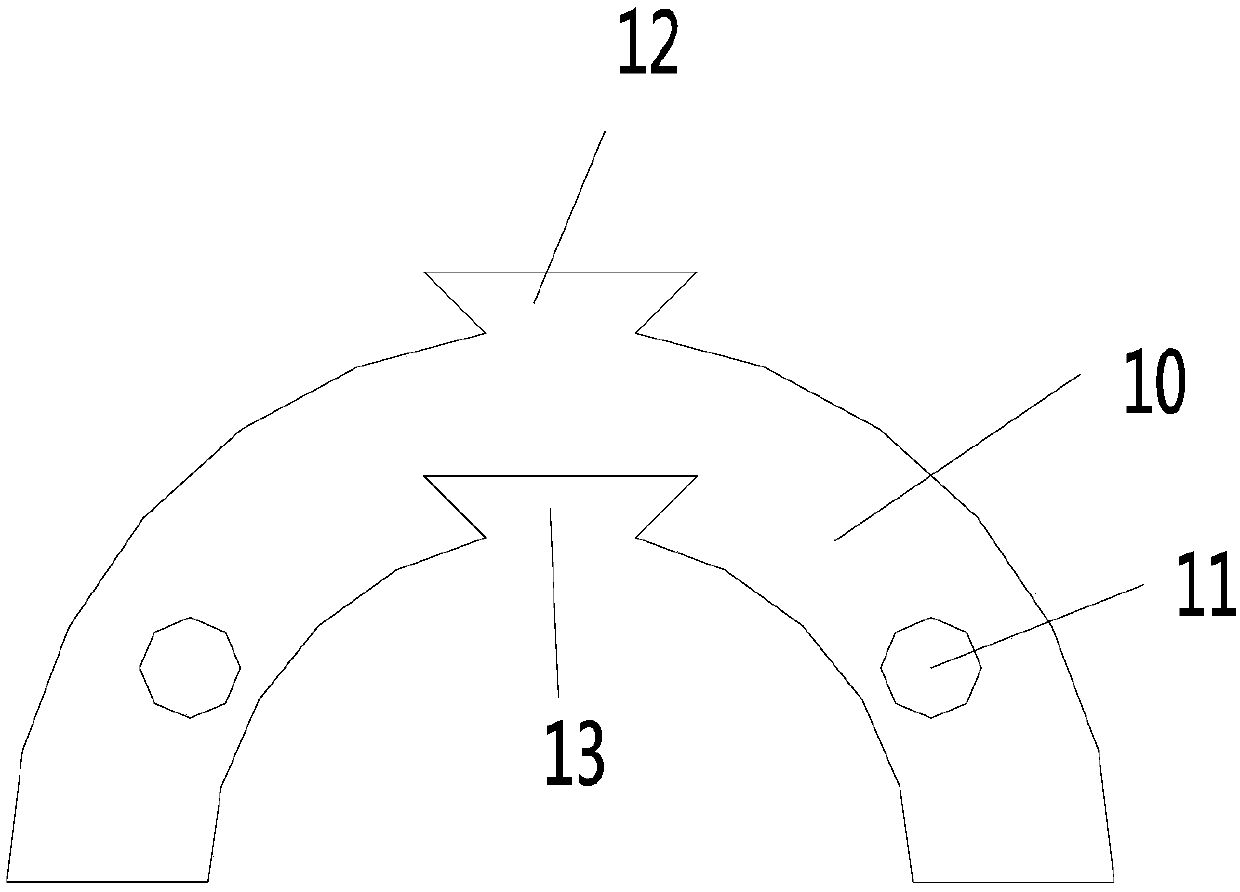

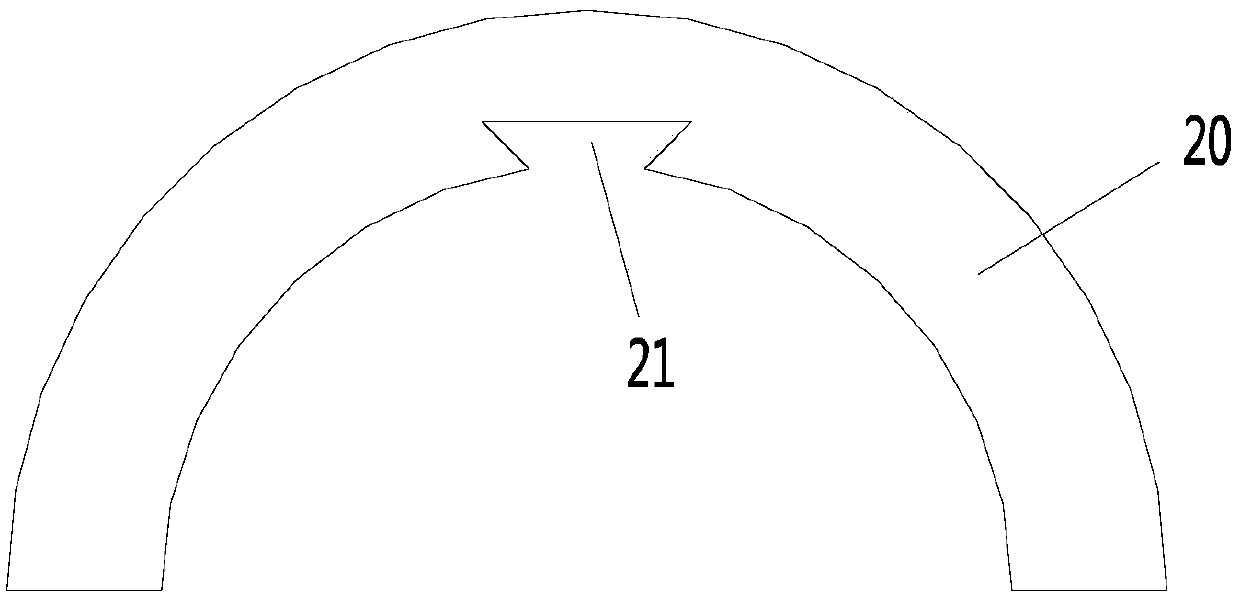

[0029] see in conjunction Figure 1 to Figure 6 As shown, according to the embodiment of the present invention, a balance assembly is provided. The balance assembly includes a first balance piece 10 for fixing on the rotor 2 and a handle for adjusting the balance assembly that can be assembled on the first balance piece 10. The weight and / or the second balance of the distance from the center of gravity of the assembly to the centerline of rotation of the rotor 2 . The present invention can adjust the weight of the balance assembly and / or the distance between the center of gravity of the balance assembly and the center line of rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com