Novel motor wind path structure

A new type of wind circuit technology, applied in the field of motors, can solve the problems of poor cooling effect of motor windings and iron cores, and achieve the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

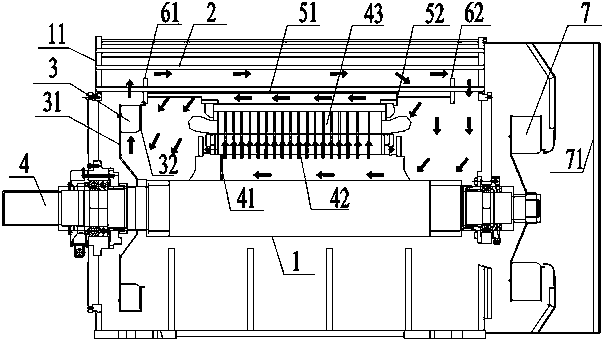

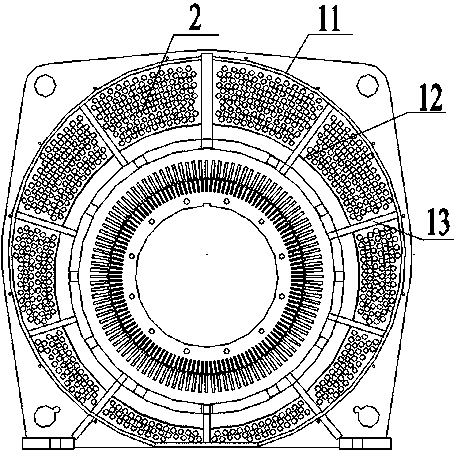

[0015] The present invention provides a new motor air path structure, such as figure 1 with figure 2 As shown, it is especially suitable for flameproof self-lubricating motors (IC511 motors for short). The new motor air duct structure includes a machine base, a cooling pipe 2, an axial rib 13 and an inner fan 3, the machine base includes a machine base body 11, a machine base inner ring 12, and the machine base body 11 and the machine base inner ring 12 There is a cooling cavity in the middle, and a plurality of axial ribs 13 are arranged at intervals along the circumferential direction in the cooling cavity, and each axial rib 13 is fixedly arranged with the machine base. Preferably, the axial ribs 13 are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com