a terminal device

A technology of terminal equipment and discharge end, which is applied in the field of terminal equipment, can solve problems such as the inability to discharge static electricity in the restricted area of the antenna, the inability to ensure the uniformity of glue dispensing, and the excessive glue in the area, so as to ensure the consistency of electrostatic protection and effective electrostatic protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

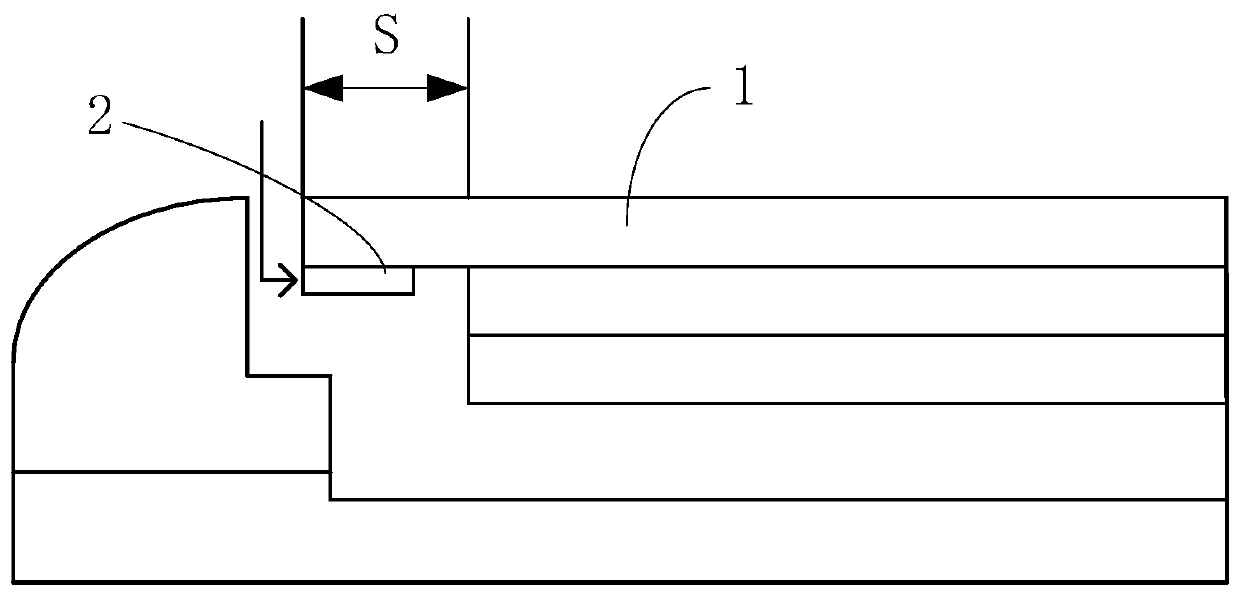

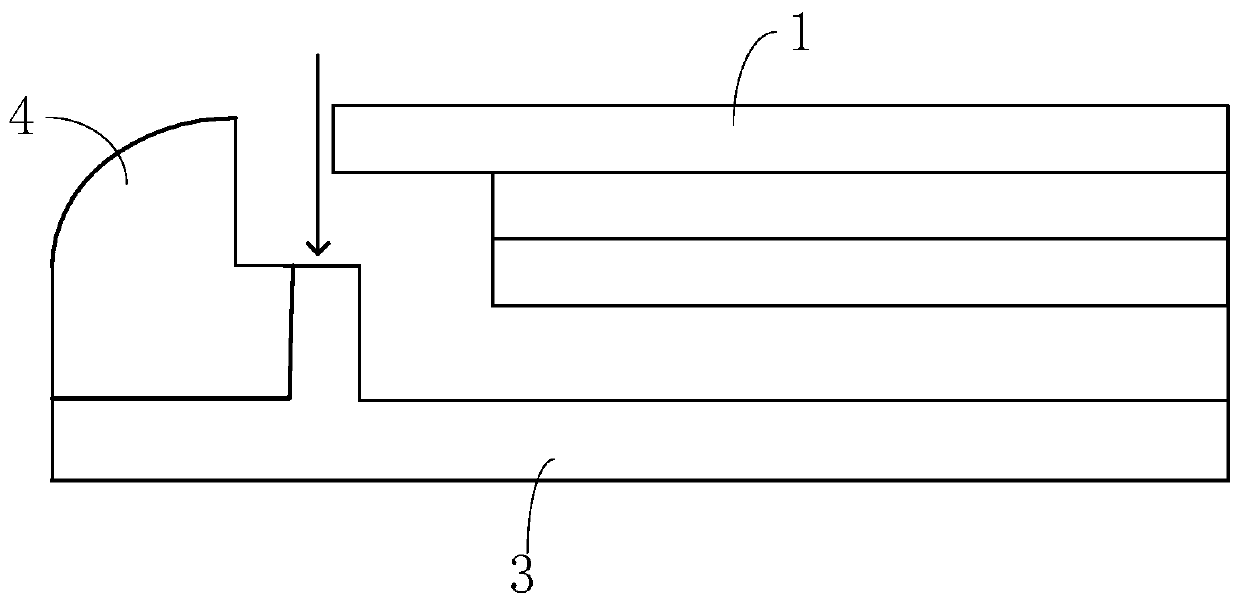

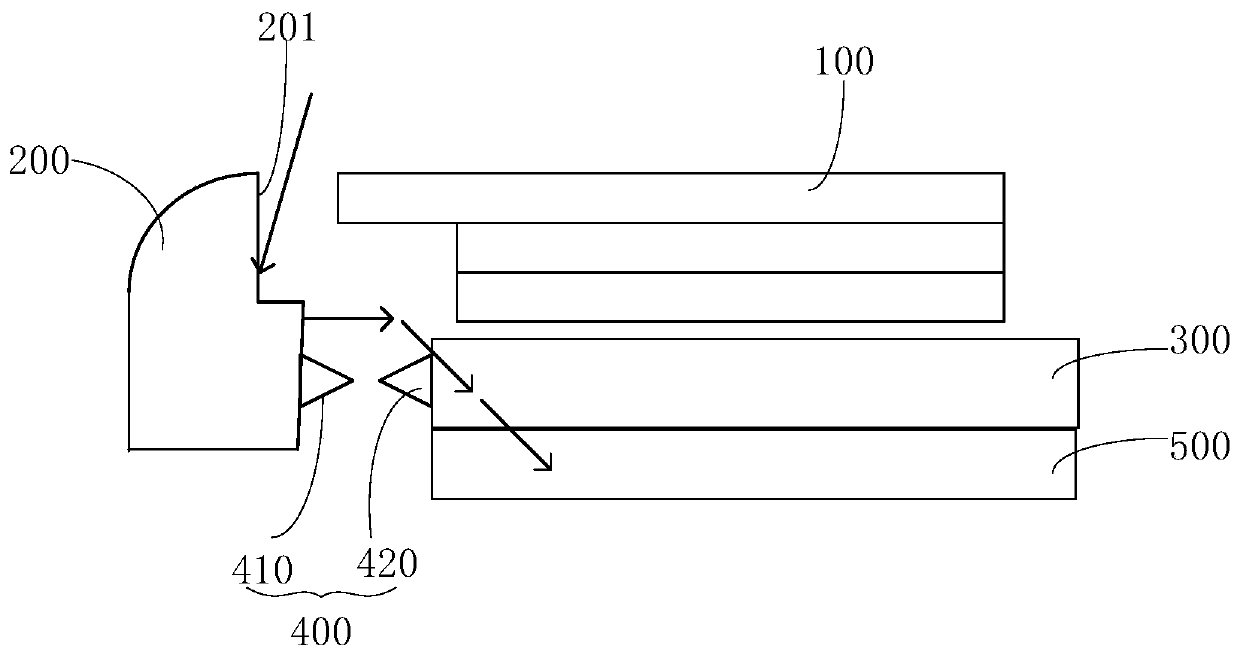

[0039] Such as image 3As shown, in this embodiment, the electrostatic protection structure 400 includes multiple sets of discharge components; each set of discharge components includes: a first discharge terminal 410 disposed on the metal surface of the support 200, the first discharge end 410 A discharge end 410 includes a first sharp portion; and, a second discharge end 420 disposed on the metal middle frame 300, the second discharge end 420 includes a second sharp portion; wherein the first discharge end 410 and the second The discharge ends 420 are arranged at a predetermined distance apart, and the first sharp portion is opposite to the second sharp portion.

[0040] In the above solution, the static electricity protection structure 400 is implemented by using two discharge terminals respectively arranged on the metal surface of the bracket 200 and the metal middle frame 300. When static electricity enters from the side of the screen module 100, due to the The two disch...

Embodiment 2

[0048] Such as Figure 4 As shown, in this embodiment, the electrostatic protection structure 400 includes an ESD (Electro-Static discharge, electrostatic discharge) device disposed at the gap between the inner surface 201 of the bracket 200 and the metal middle frame 300 , the ESD device 403 includes a first port and a second port, the first port is connected to the inner surface 201 of the bracket 200 , and the second port is connected to the metal middle frame 300 .

[0049] Using the above solution, the electrostatic protection structure 400 is realized by using the ESD device 403, by connecting the two ports of the ESD device 403 to the metal surface of the bracket 200 and the metal middle frame 300 respectively, when there is static electricity on the side of the screen module 100 When entering, because the first port of the ESD device 403 is in contact with the metal surface of the bracket 200, and the second port of the ESD device 403 is in contact with the metal middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com