Electrostatic protection device and manufacturing method thereof

A technology of electrostatic protection device and manufacturing method, which is applied in the semiconductor field, can solve problems such as false triggering of parasitic SCR, and achieve the effect of avoiding false triggering of latch phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below, but it should be explained, and these embodiments are not intended to limit the functions, methods, or structural equivalent transformations or substitutions of these embodiments according to these embodiments. It is within the scope of the invention.

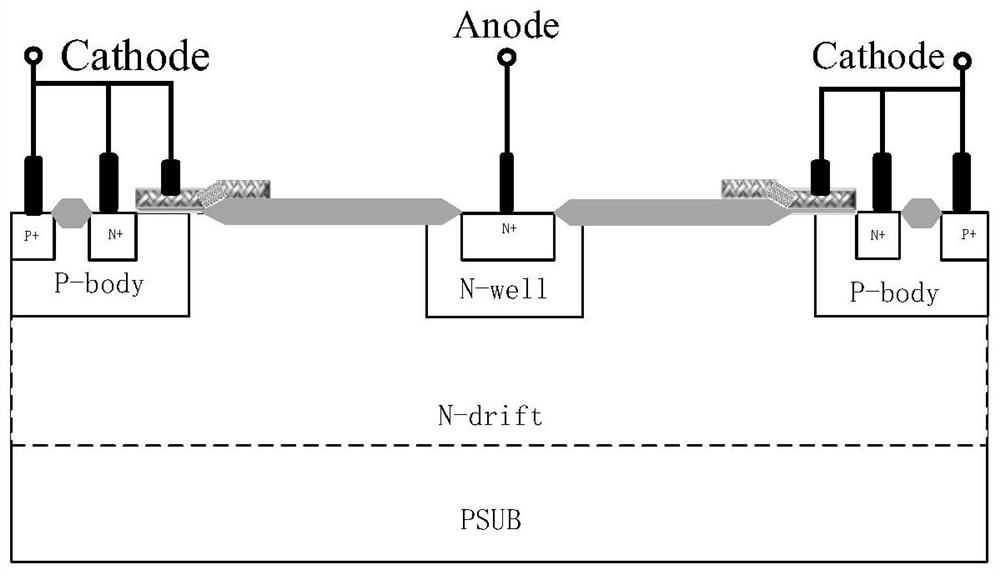

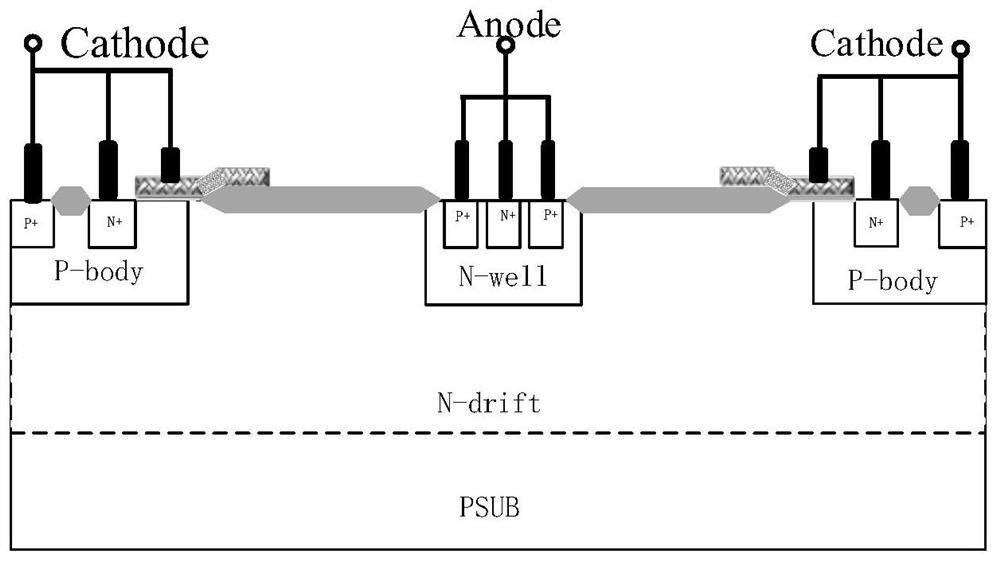

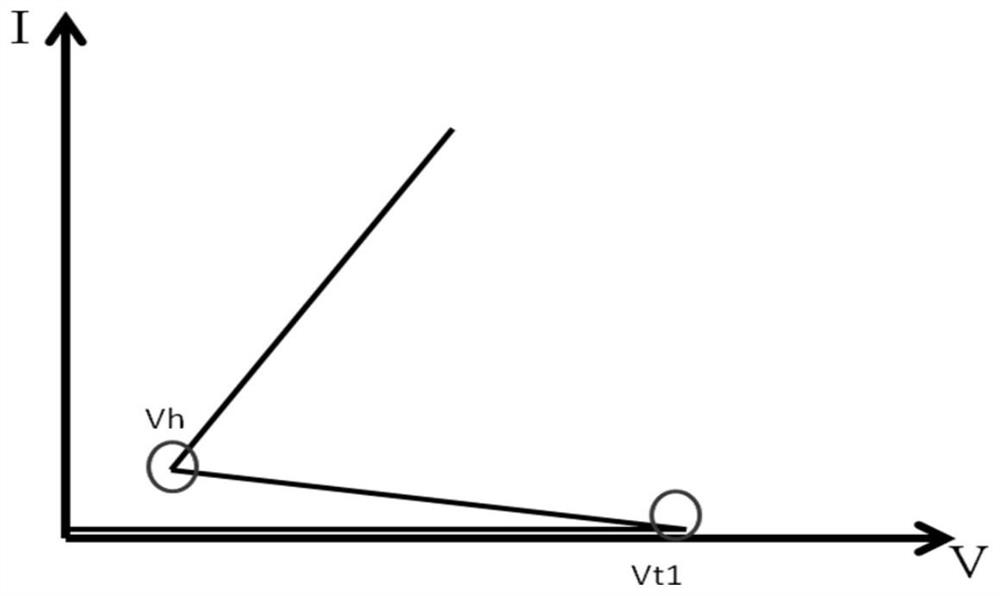

[0038] As described in the conventional LDMOS-SCR structure, it is prone to the latching effect, which is prone to the devices to be burned after misconcing. After the applicant has undergone this phenomenon, the principle of discovering the technical problem is as follows: For a traditional LDMOS-SCR structure, its equivalent circuit is like figure 2 As shown, two symmetric distributed MOS devices, wherein N-Well constitutes a drain region, and since a n-type retaining region is included in the drain region, a N-type diver is included, each MOS is included. The devices produce parasitic triode NPN and PNP. When the ESD pulse is in the ESD pulse, the positive voltage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com