Roll stand and method for changing work rolls

A technology for rolling mill stands and work rolls, applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., capable of solving problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

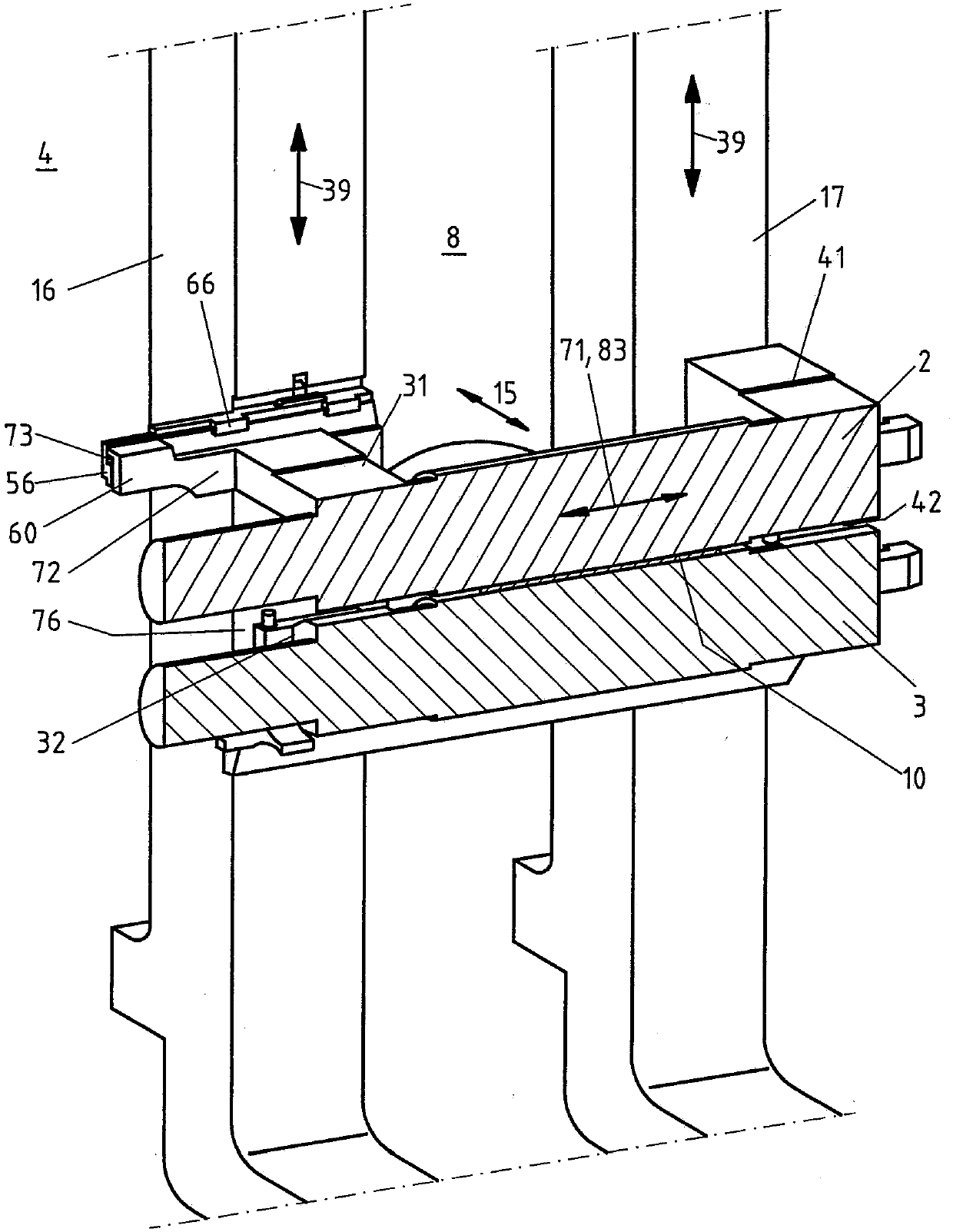

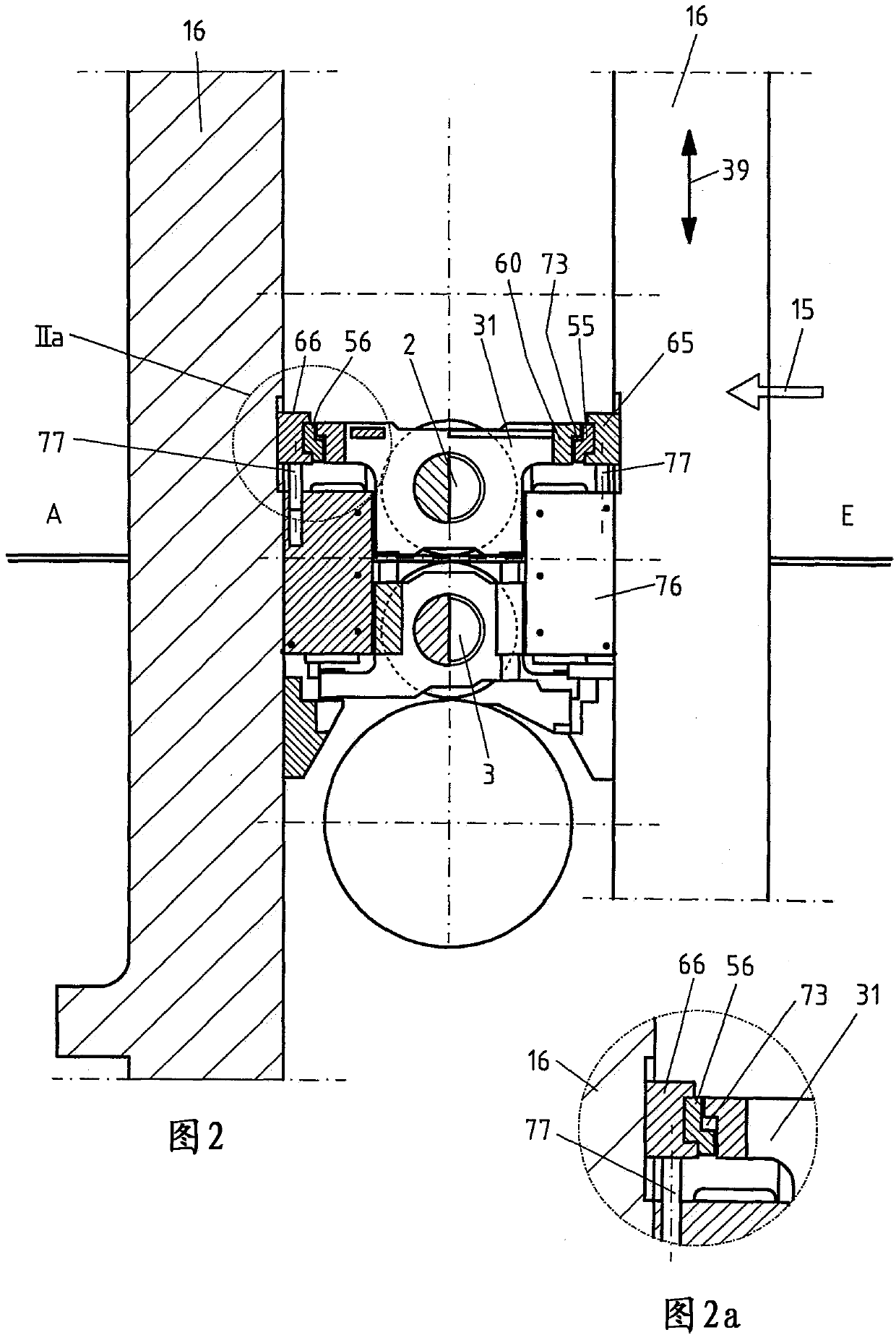

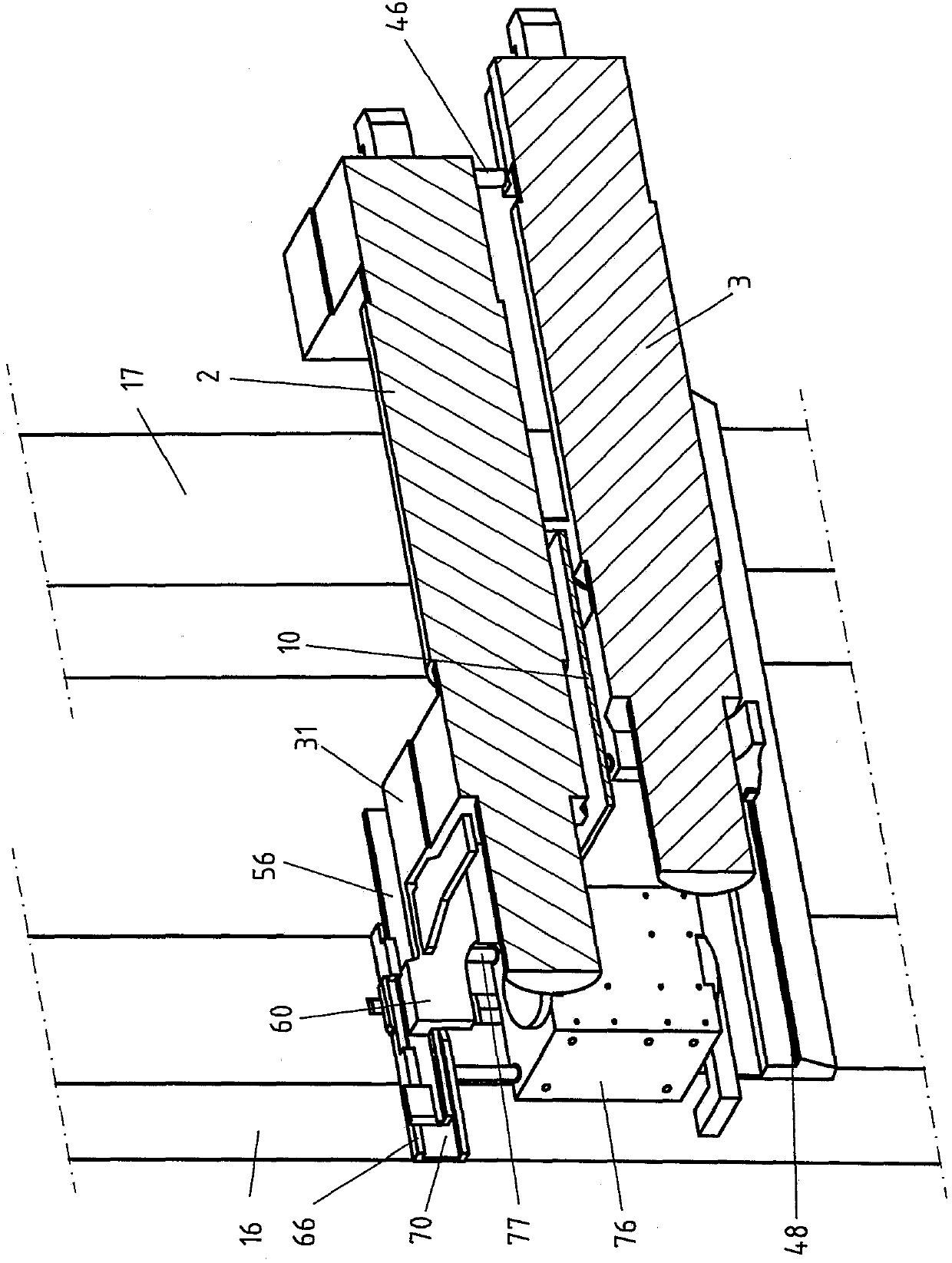

[0050] figure 1 A longitudinal section view of the rolling mill stand 4 is shown. The upper work roll 2 and the lower work roll 3 form a roll pair and form a roll nip at the rolling line 8 in which the rolling stock 10 is rolled. The rolled product 10 is, for example, a flat metal strip.

[0051] The rolling line 8 extends along the rolling direction 15 between the rolling stand column 16 on the drive side of the rolling mill stand 4 and the rolling stand column 17 on the operating side. The rolling stand column 16 on the drive side is characterized in that a drive unit (not shown) for rotationally driving the work rolls 2 and 3 is arranged here.

[0052] The upper work roll 2 is rotatably supported in the mounting member 31 on the driving side and the mounting member 41 on the operating side. Similarly, the lower work roll 3 is rotatably supported in the mounting member 32 on the driving side and the mounting member 42 on the operating side. Mounting pieces 31, 41, 32, 42, also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com