Tower for a wind turbine

A technology for wind power generators and pipe towers, applied in wind power generation, installation/supporting configuration of wind power engines, engine manufacturing, etc., can solve the problems of expensive grid support structure, impact on accessibility, high cost, etc., and achieve simple and reliable Effects of contactability, optimized force transmission, simplified accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

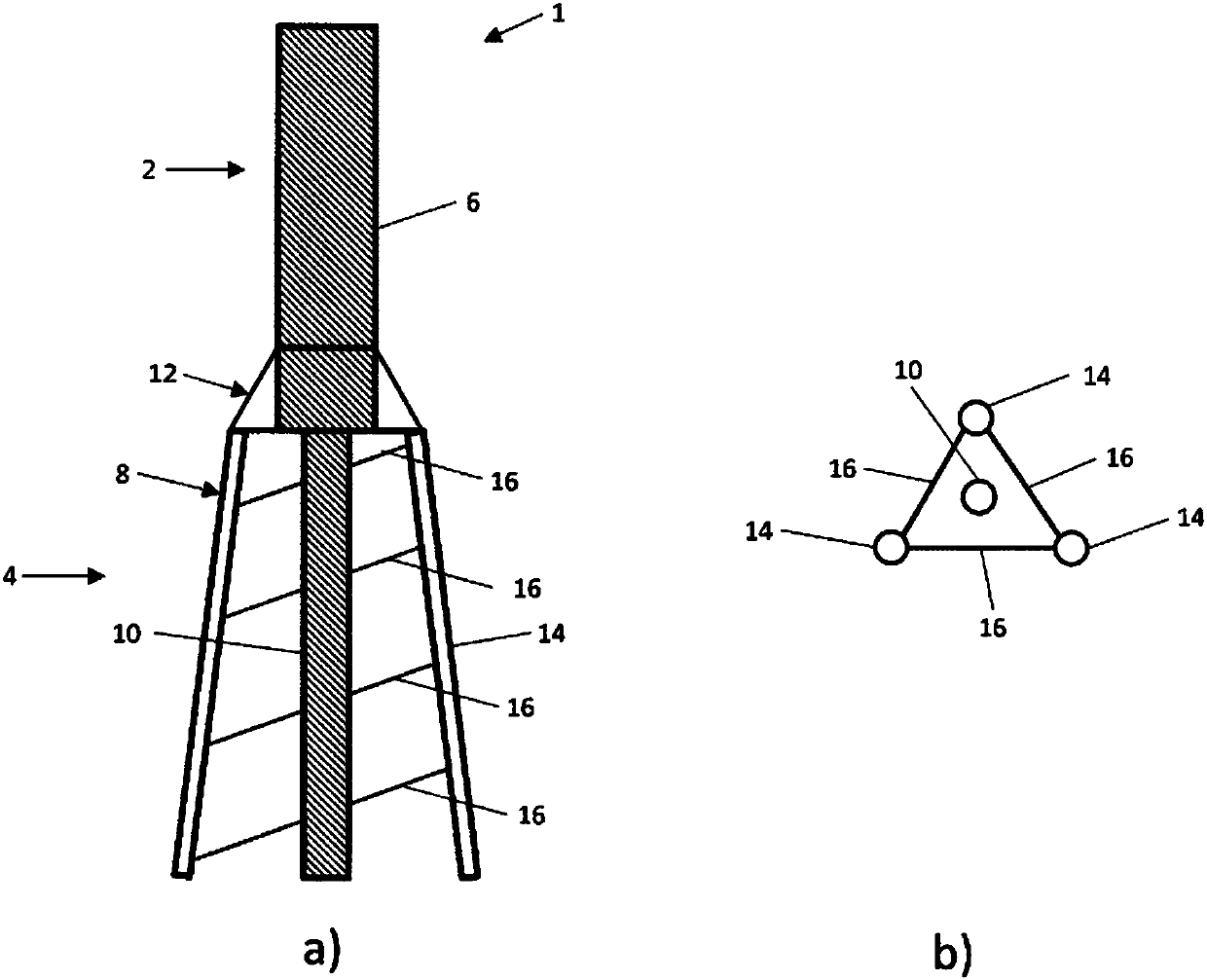

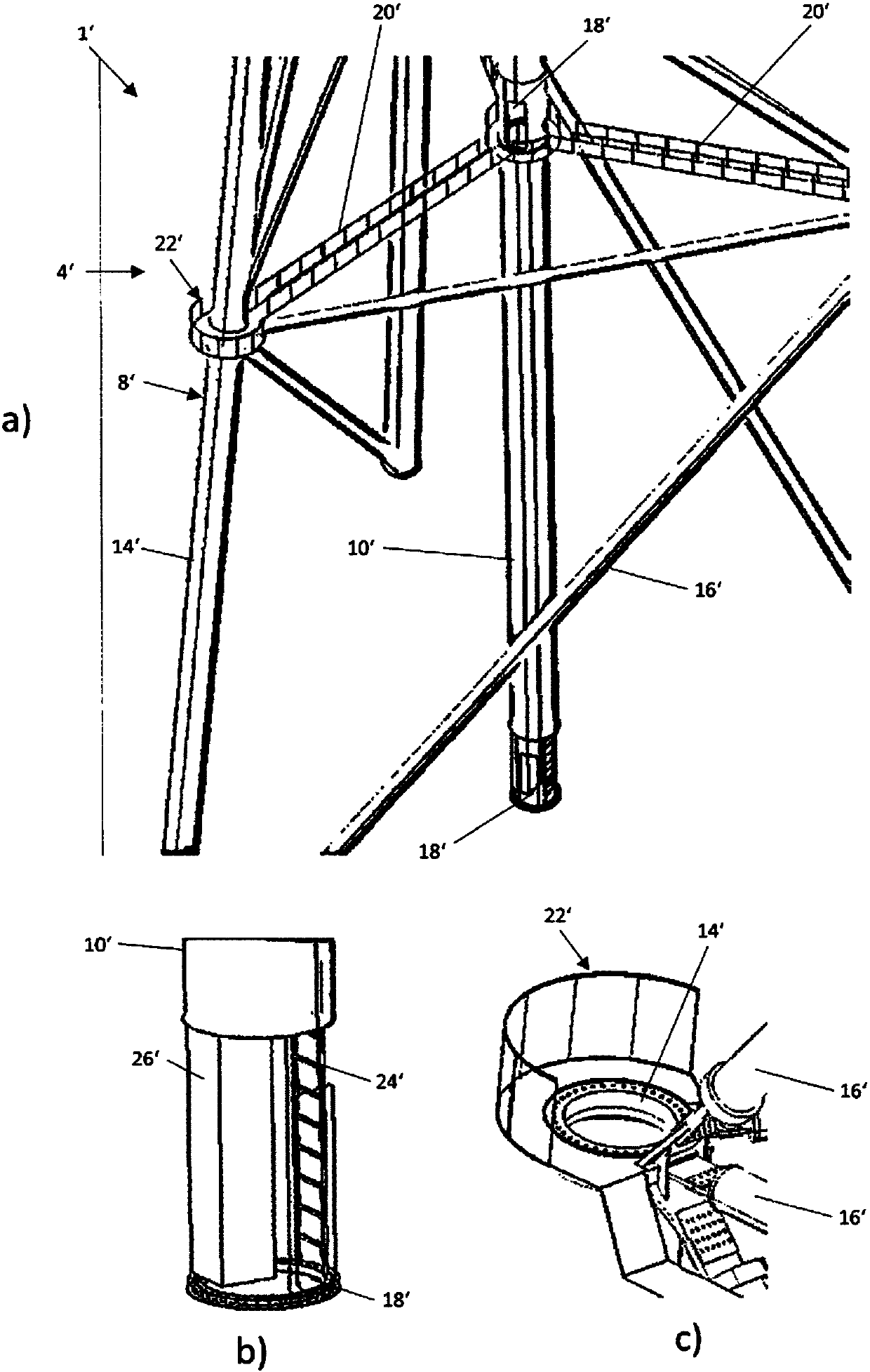

[0042] figure 1 a shows a longitudinal section of a first embodiment of a tower according to the invention, while figure 1 b shows figure 1 a Cross-sectional view of the embodiment shown.

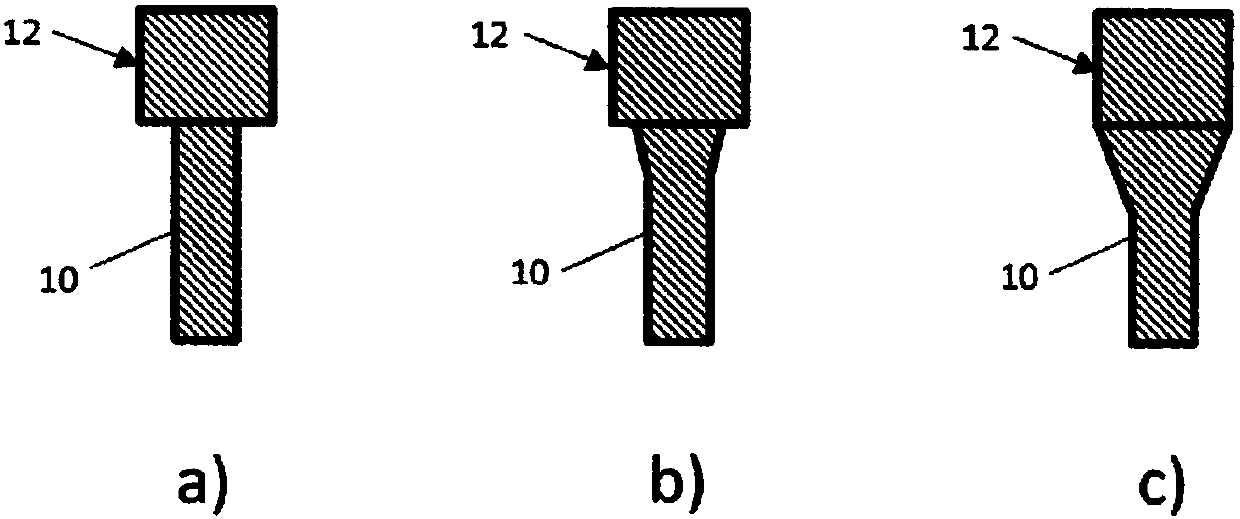

[0043] The tower 1 is part of a wind generator with a nacelle and a rotor (not shown). Column 1 has an upper column section 2 and a lower column section 4 . The upper column section 2 comprises a tube column 6 . The lower tower section 4 comprises a lattice frame 8 and an intermediate pipe 10 which is arranged centrally inside the lattice frame 8 . The intermediate tube 10 generally has a smaller diameter than the tube column 6 of the upper column section 2 . The tower 1 also comprises an intermediate part 12 through which the lattice frame 8, the intermediate pipe 10 and the tube tower 6 are connected to each other. The intermediate pipe 10 is connected at its lower end to the base (not shown) of the column 1 and at its upper end to the intermediate part 12 .

[0044] The central tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com